Industrial automation and digitalisation are constantly boosting the economy. With its future-oriented Industry 4.0 project, the German government is even promoting the development of the ‘smart factory’ – a kind of intelligent factory that largely organises itself without human intervention. The ‘Internet of Things’ is designed to help with this: the Internet of Things (IoT for short) allows all devices to independently collect and process data and communicate with each other (machine-to-machine). This approach is designed to optimise processes, increase performance and minimise errors.

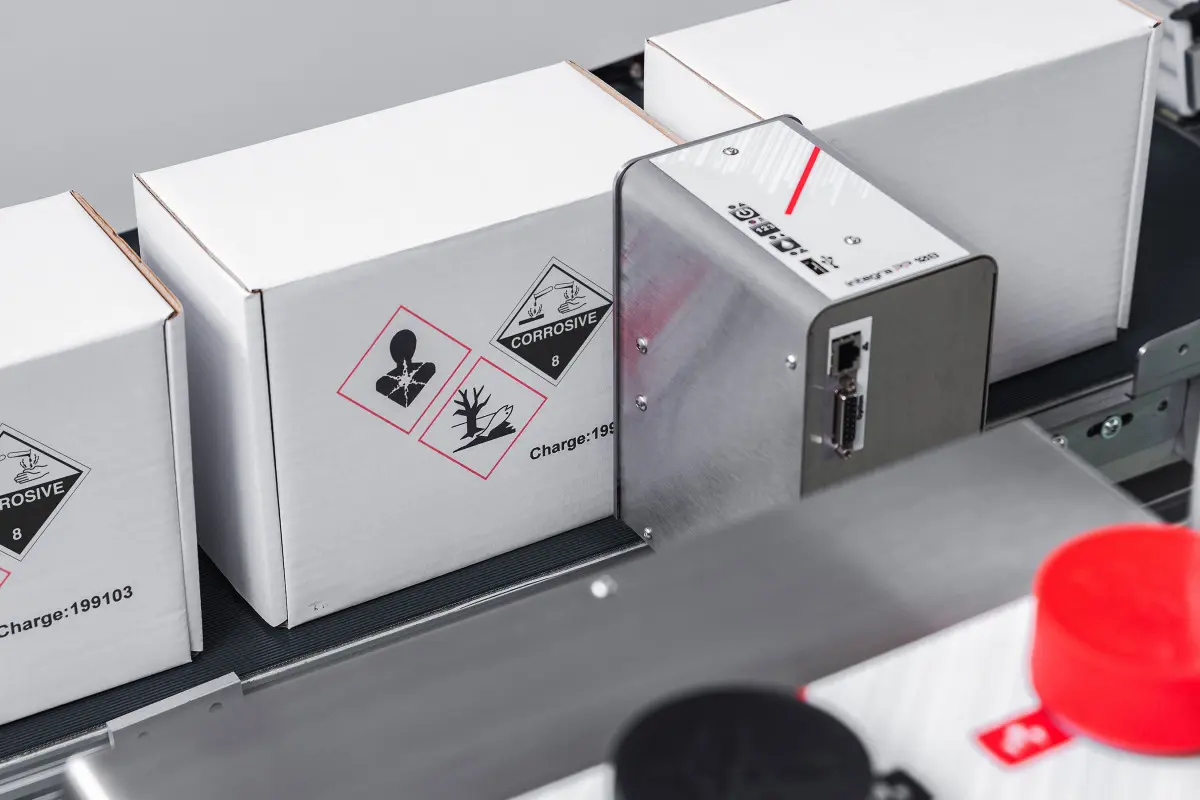

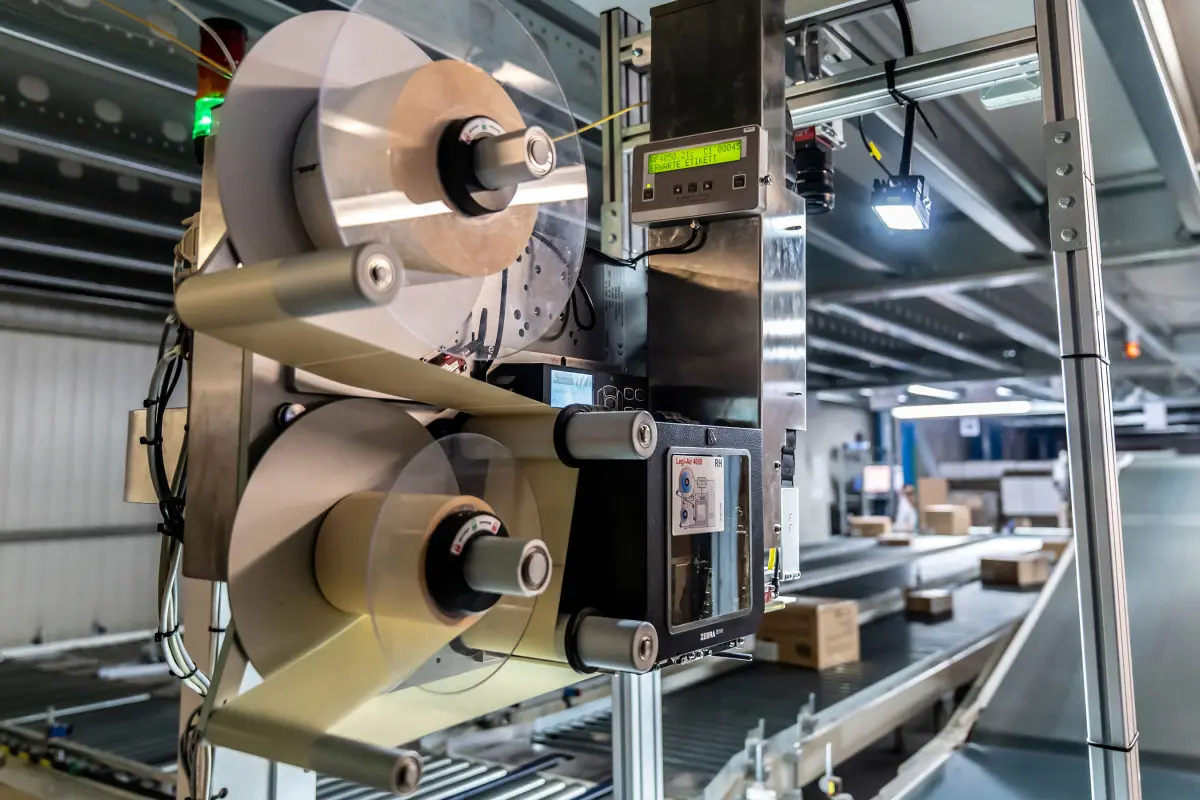

Although many companies still have a long way to go, many processes can already be automated today. This also applies to the labelling of your products. If you want to increase productivity and simplify quality assurance, Weber Marking Systems is the right partner for you.

More productivity, fewer errors

Of course, people will always be indispensable, but their role is changing increasingly: instead of carrying out individual production steps by hand, they take on the overarching control and monitoring of all processes. The actual ‘manual work’ is done by machines and computers, which in turn are networked with each other and thus control production all by themselves.

The advantages are obvious:

- The labelling quality is improved and remains constant

- Production output is increased because products can be marked faster (even with a high degree of customisation)

- The error rate is greatly reduced

- Production downtimes are reduced by IT-supported systems

- People are relieved of monotonous work, for example by robots assisting the marking systems

- Personnel costs are saved

- Intelligent asset tracking and asset management is made possible