Lux Elements

Bathroom designers swear by rigid foam panels. They can be used not only to cover walls and floors, but also to design entire elements such as washbasins, shower trays and bathtubs. Lux Elements GmbH & Co. KG in Leverkusen offers a sophisticated range of technical systems made from rigid foam carrier elements that can be used to implement a wide variety of design ideas. Lux Elements labels its products and packaging with systems from the labelling supplier Bluhm Weber Group.

Products

Label it big – print it small

At Lux Elements, the cardboard boxes are labelled with a 600-millimetre-long strip of labels on the front and left-hand side. ‘Sticking such a strip on without any bubbles or creases is a challenge,’ says Deniz, Production Manager at Lux Elements.

‘One of the special features of our products is their environmental friendliness,’ explains Bernd Richter, Marketing Manager at Lux Elements. This is because the rigid foam made of expanded polystyrene (EPS) is foamed in the company's own factory in France without the use of environmentally harmful propellants, but only with the aid of steam. This means that the material is not only easy to recycle. ‘Due to their water resistance and mould resistance, our rigid foam products are particularly suitable for use in bathrooms, spas and wellness areas.’

During production, the rigid foam panels from Lux Elements are coated with a mixture of mortar and glass fibre fabric. This not only makes them extremely stable and resilient, but also provides an ideal substrate for optimum adhesion of tile adhesives and plasters. After finishing and packaging, the Lux Elements products are labelled.

Up to 300 packaging units per hour are labelled at two different stations using two different label formats. While several label dispensers apply long label strips with batch information to two sides of the carton, a high-performance labeller applies very large design labels to the top of the cartons.

Side label strips

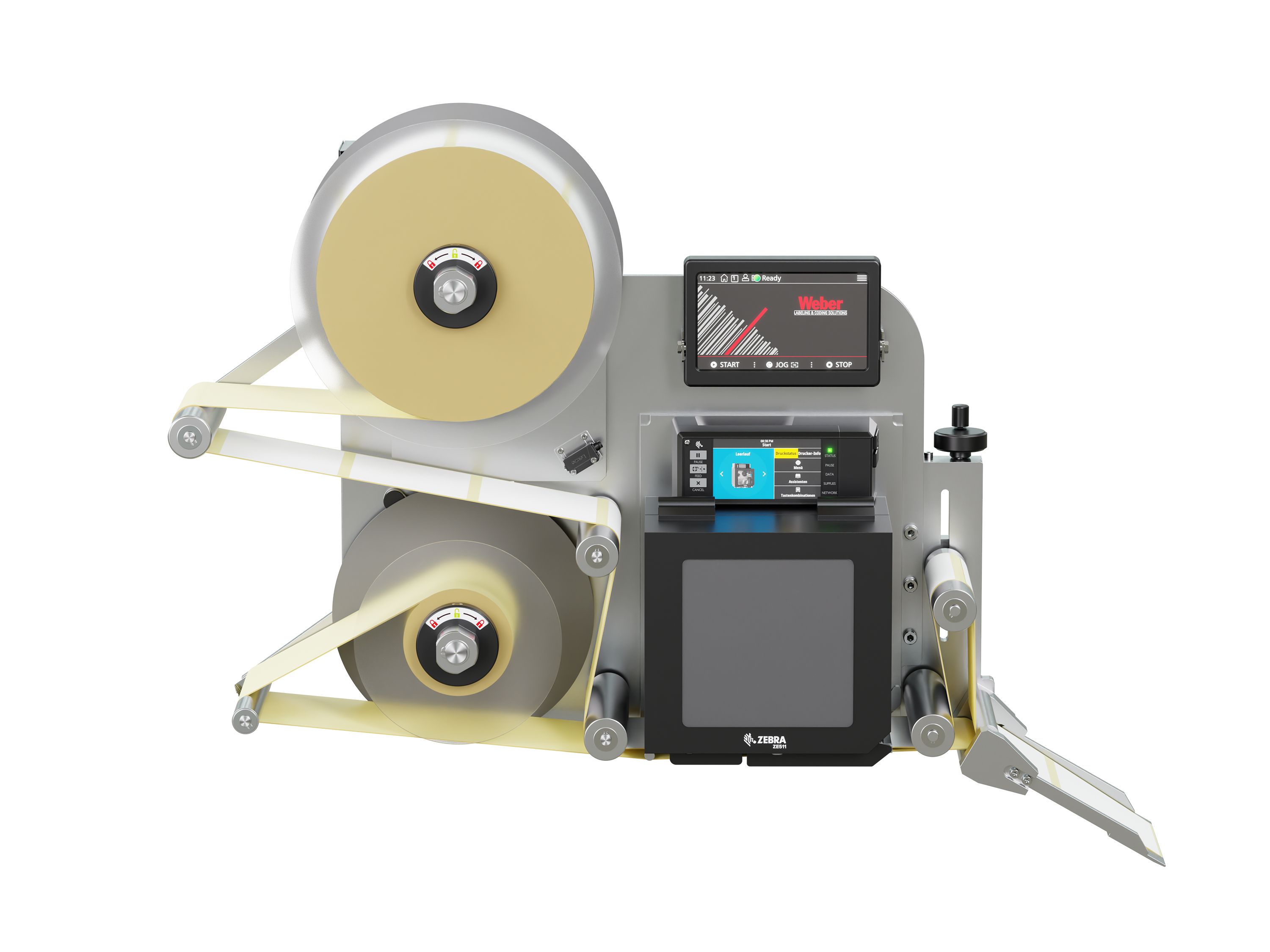

At Lux Elements, the cardboard boxes are labelled with a 600-millimetre-long label strip on the front and left side. ‘Applying such a strip without bubbles or creases is a challenge,’ explains Deniz s, Production Manager at Lux Elements. Lux Elements uses three Legi-Air 4050 WO label print dispensers from the Bluhm Weber Group portfolio for this purpose. These devices use the wipe-on method to apply the labels precisely. The labels ‘waiting’ at the front of the dispensing edge are wiped over the entire length of the product surface. To ensure that the labels do not tear off or crease, they must be fed through the dispenser at exactly the same speed as the conveyor belt.

The 50 or 100 millimetre wide labels are individually printed with product and batch information. The print module integrated in the Legi-Air 4050 WO must therefore also be able to adapt to the speed of the conveyor system. An Avery-Novex DPM print module was selected for this purpose. Its print speed can be adjusted in very small increments of five millimetres per second, allowing it to be easily aligned with the conveyor belt speed. With a maximum print speed of 400 millimetres per second, the printer can keep pace with conveyor belt speeds of up to 24 metres per minute.

The Avery-Novex DPM also features automatic film saving. Print modules that use thermal transfer printing require a thermal transfer film in addition to the label material. Both rolls are guided along each other so that the ink on the film can be transferred precisely to the labels during printing with the aid of heating elements. As an environmentally friendly thermal transfer print module, the Avery-Novex DPM is equipped with ‘RibbonSave technology’. This allows the printer to determine at which points in the printing process no ink or ribbon is required. When the unprinted area reaches a certain size, the ribbon is stopped and lifted off the label while the label roll continues to run. As soon as it is needed for printing again, the thermal transfer foil is repositioned and starts moving again. This saves a lot of valuable foil during operation. The foil roll also needs to be replaced less often. This reduces the total cost of ownership.

‘We design our labels using Nice Label design software, which is linked to our database,’ reports Deniz Yildirim. ’This means that the variable fields are filled in automatically.’

Decorative label

The tops of the packaging units are also affixed with a design label that shows the contents of the package as well as test seals and relevant industry standards. With a width of 300 millimetres and a length of 600 millimetres, this label is very large. ‘For this size, we use the Alpha HSM labeller from Bluhm Weber Group,’ explains Deniz Yildirim. This high-performance labelling system can be assembled in a modular fashion and, depending on the dispensing tongue, can process label dimensions of up to 320 millimetres wide and 2,000 millimetres long.

The label size also means that the label rolls are very heavy. The Alpha HSM therefore has unwinder with its own servo drive. They adjust the unwinding of the label webs to the speeds of the labeller and conveyor technology so that the label rolls do not tear or crease.

Mobile inkjet printer

In addition to labelling the packaging units, Lux Elements uses another marking device from Bluhm Weber Group. The Markoprint Handhold mobile inkjet printer is used to mark the raw products with the respective batch number before packaging. The Handhold is a thermal inkjet printing system with a handle that can be used wirelessly. ‘The mobile printer is not only very easy to use, but also extremely practical, as we can use it anywhere,’ says Deniz Yildirim.

The print information for the Handhold can consist of text, data, barcodes or logos and can be easily created on a PC using the iDesign layout software supplied. The operator transfers the design to the Handhold via a USB stick, where up to nine different templates can be stored. When changing products, switching to different print texts is done at the touch of a button.

Thanks to a wide range of inks, the handheld device can be used to mark a wide variety of surfaces, from smooth to absorbent. Print images with a resolution of 600 dpi and a height of up to 12.5 millimetres can be achieved. The powerful battery is located in the handle.