moin robotics

Moin robotics GmbH, based in Tornesch near Hamburg, is a specialist in robot integration in manufacturing and intralogistics. The experts at moin robotics developed a robotic labelling system for a chemical industry group that labels IBCs (intermediate bulk containers) and drums for technical waxes fully automatically. Four labelling systems and a belt applicator from Bluhm Weber are used in the process.

Products

High performance in the smallest of spaces

‘The customer needed to label containers with chemical liquids in a very confined space using different label formats,’ explains Lars Kobialka. ‘Together with Bluhm Weber, we developed a highly flexible and adaptable robot cell that prints and applies hazardous substance and product labels with high performance and quality.’

The machine manufacturer develops, manufactures and integrates flexible automation solutions. ‘We see ourselves as problem solvers for industry. Whenever complex tasks in production need to be automated, we develop innovative robot concepts. This is how we help our customers simplify their processes,’ explains founder and managing director Lars Kobialka.

The challenge

- Limited space

- High number of labels to be applied

- Distance between labelling systems and IBCs/barrels

The result

- Applying hazardous substance and product labels in a confined space

- Four labelling systems and a belt applicator mounted on a cobot

- Flexible, automatic and Industry 4.0-compatible labelling solution

Automation solution for Industry 4.0

The system consists of a Universal Robots UR10e cobot, which is placed in the centre of a stable strut profile and flanked by four Bluhm Weber labelling systems. On one side of the cobot, three Alpha Compact label dispensers are mounted one above the other, each dispensing a different hazardous substance label. As the name suggests, the labelers are particularly space-saving. At the same time, they work quickly, precisely and are particularly easy to operate. The label dispensers process labels up to a width of 120 mm.

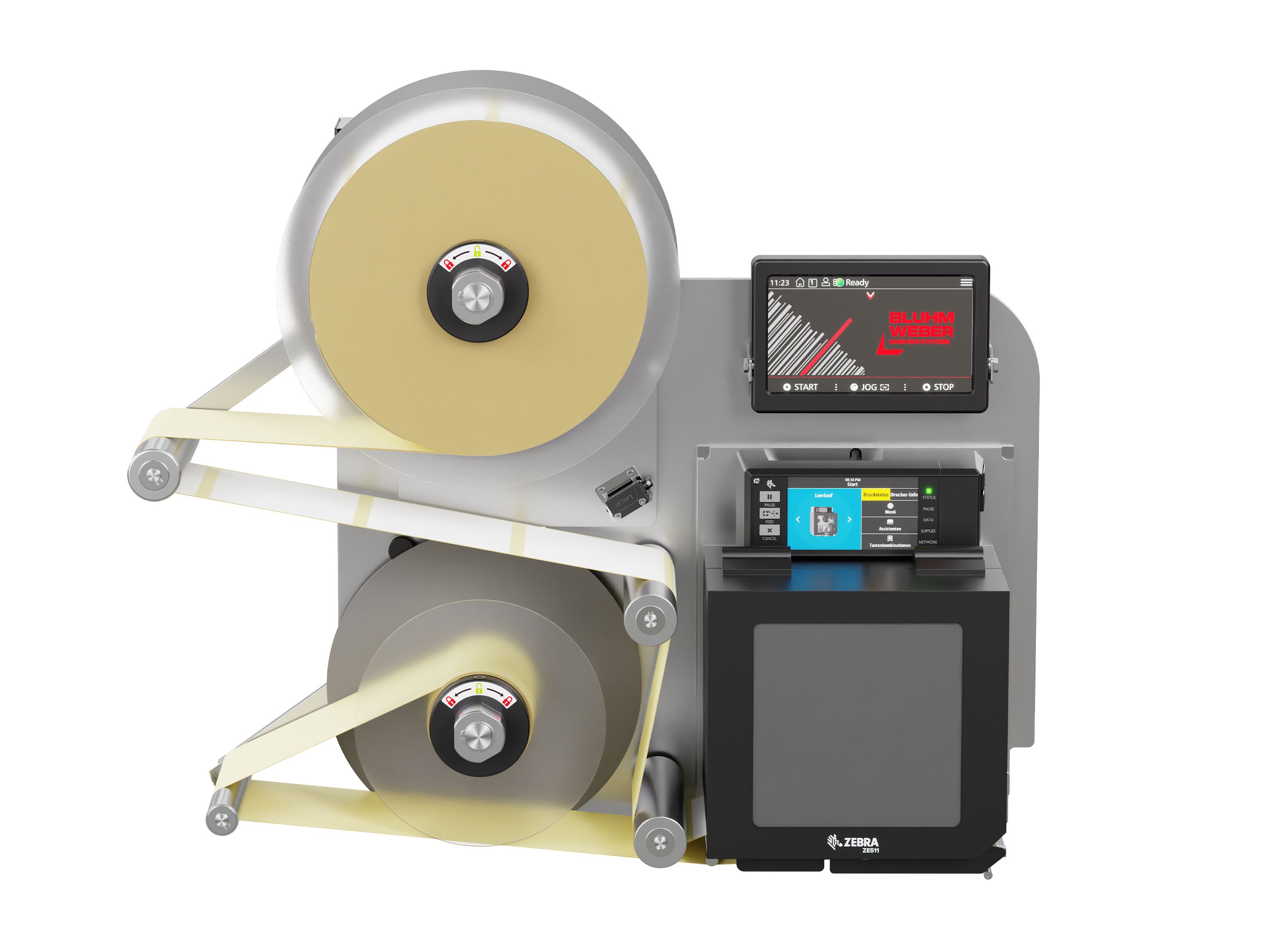

On the other side of the cobot is a Legi-Air 4050 B-R label printer, which prints and dispenses individual product labels with a width of up to 6 inches – a good 175 millimetres. Thanks to its flexible interface to the customer's software, it can be easily integrated into processes. This allows variable print information to be transferred directly to the print module. In this case, a Zebra print module was integrated, which guarantees high printing speed and resolution as well as durability. No applicator was installed on the print dispenser itself for the robot application; instead, the labels are transferred by the robot-controlled belt applicator. Like all labelling systems from Bluhm Weber, the devices used are very robust and suitable for continuous 24/7 operation.

Flexible robot labelling system

In the application, the cobot moves alternately in front of the dispensers. A specially optimised belt applicator is installed on the robot arm. This takes the label directly from the dispensing edge of the respective labelling system. The cobot then moves – with the label on the applicator – to its destination on the line and applies the label precisely to the required position on the IBC or barrel. The particular advantage of the belt applicator is that it can handle a wide range of label formats – a flexible bonus when large-format labels are required, for example.

In addition, the solution is flexible in terms of duplication and can be supplemented with other hardware. For example, a 4-colour label printer can be integrated if required. The system can also be equipped with other labelling systems from the Bluhm Weber portfolio. Of course, the robot cell also allows the use of other robot models that cover larger ranges, for example. Even the future has been taken into account: if required, the system allows the customer to apply tamper-evident seals to the top of the containers to secure the contents.

Fully automatic quality control

Two integrated camera systems complete the system by monitoring the entire labelling process. ‘One camera system detects the position of the drums and determines the labelling position,’ explains Development Manager Björn Möser. ’The second camera is located on the robot-controlled belt applicator. This allows us to determine the position of the label plates on the IBCs and carry out quality control by visually checking that the correct label has been applied.’

Space and flexibility challenges solved

The particular challenge was to achieve a high cycle rate with minimal space requirements while remaining flexible in application. Thanks to the compact components, this task was solved excellently. The system also remains flexible and can be easily converted for other processes. The labelling process has not only been automated, but also accelerated: with the solution from moin robotics, the IBCs and drums are labelled with up to 360 labels per hour, depending on the settings.