Sonae Arauco

The Portuguese-Chilean wood-based materials manufacturer Sonae Arauco produces a wide variety of MDF boards at its Meppen site. The products are labelled using a collaboration between a labeller and a robot. This is based on a labelling system with special labels from the labelling provider Bluhm Weber Group.

Products

Firm hold and residue-free removal of labels

‘A particular difficulty was to apply a label with permanent adhesion to products that vary in length, width, height and properties. After intensive market research, we decided on the system from Bluhm Weber Group. A particular challenge in this project was to develop the robot applicator in such a way that the label is applied from the printer to the applicator without any problems. We were able to draw on Bluhm Weber Groups experience in the design and development of the applicator for label pick-up. In automating the process, we worked with Bluhm Weber Group to develop a label that adheres cleanly and firmly to the package but can also be removed without leaving any residue or damaging the product. During the implementation of the project, we received excellent support from Bluhm Weber Group and their service staff.’

The challenge

- Large distance between labeller and pallet

- Wood fibre is a poor adhesive substrate

- Uneven surfaces depending on further processing

The result

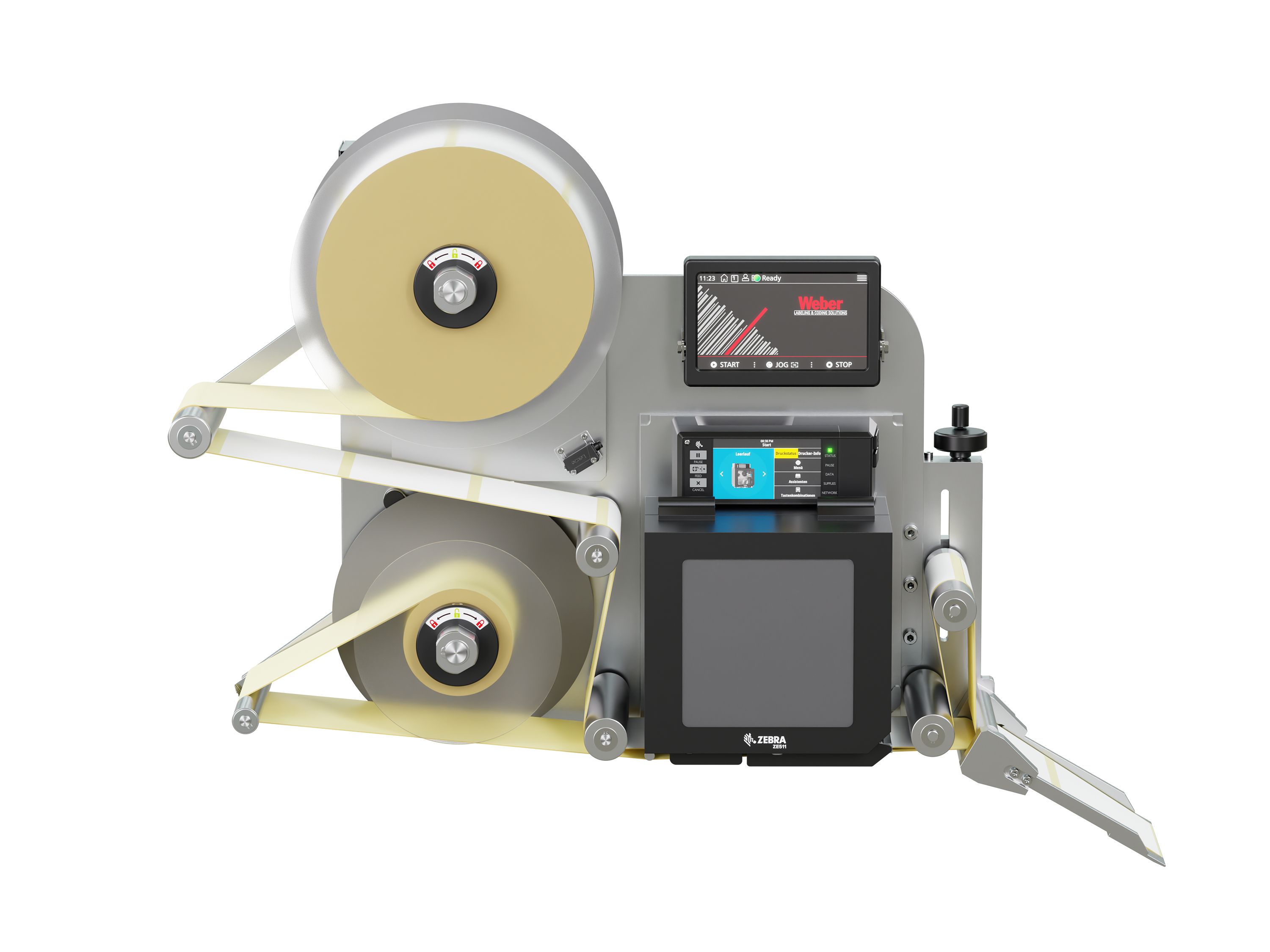

- The Legi-Air 4050 WO label printer is housed in an air-conditioned cabinet

- A robot transports the label to the product and sticks it on

- The labels with special adhesive adhere reliably even to special solutions

- A sponge applicator presses the label firmly onto the surface after application

‘MDF board’ is a well-known term and stands for “medium-density fibreboard”. MDF boards are not only found on walls, ceilings and floors. They are also used as furniture fronts and table tops. The Portuguese-Chilean wood-based materials manufacturer Sonae Arauco produces MDF boards in a wide variety of designs at its Meppen site.

‘MDF" To produce MDF, wood is defibrated, mixed with adhesive and pressed. Compared to solid wood, MDF boards not only make house and furniture construction more flexible. The possibility of using recycled material also makes fibreboard more sustainable. The Meppen site of Sonae Arauco Deutschland GmbH was founded in 1961 as a chipboard production facility. Today, 200 employees produce MDF boards in various thicknesses, ranging from thin floorboards to thicker insulation elements.

Labelling robot collaboration

The boards are further processed in downstream systems according to specific orders. This results in product pallets that were previously labelled manually with a delivery note. Today, Sonae Arauco has a reliable system for labelling its products. The challenges here were that the labeller had to be positioned a long way from the pallets. At the same time, wood fibres are not particularly suitable as an adhesive substrate. In addition, the surfaces tend to be uneven depending on how they are further processed. An individual solution was devised here.

To bridge the distances between pallets and labeller, Bluhm Weber Group and IG AMEK, a specialist in robot automation, developed a labelling robot collaboration. It consists of a Kuka robot arm and a Bluhm Weber Group label printer. The labeller prints the label, the robot transports it to the product and applies it to individual labelling positions.

Challenge 1: Distance between labeller and pallet

To achieve this, the Legi-Air 4050 WO label printer from Bluhm Weber Group was installed in an air-conditioned cabinet, where it is well protected against the dusty production environment typical of the woodworking industry. The label rolls are also stored in the cabinet. The labels are printed with individual product information and barcodes. The print module receives the print data directly from the ERP system. The labeller was mounted ‘upside down’ so that the adhesive side of the label is facing upwards when it is dispensed.

The challenge here was to transport the label from the dispenser to the applicator mounted on the robot arm without any problems. The developers at Bluhm Weber Group found the solution: the gripper of the robot arm moves to dispense the label, the plate for transporting the label extends and signals ‘target reached’. The labeller then pushes the freshly printed label through an opening in the cabinet onto the applicator.

The transport plate has several holes through which the label is sucked in and thus fixed in place. Thanks to a stepped suction system with several suction circuits, the label is held securely throughout the entire feeding process. And also during transport: The robot transports the label to the product, then tilts the applicator by 90 degrees and sticks the label onto the front of the pallet. It then immediately applies the sponge applicator to press the label onto the product. The robot applicator receives the exact labelling positions automatically from the ERP system in advance.

Challenge 2: Adhesive surface

The labelling experts at Bluhm Weber Group not only develop label print dispensers as special solutions, but also have their own label production facility. In addition to the labeller-robot collaboration, they were therefore able to develop labels with a special adhesive for this application. This label material is able to adhere reliably to fibreboard of varying heights and widths, but can also be removed without leaving any residue.

Challenge 3: Uneven surfaces

Sonae Arauco also produces three-dimensional products with special grains and tongue-and-groove panels for easier further processing. Therefore, another challenge in labelling was the different contours of the products. In addition to the adhesive properties of the labels, the way in which the material is applied is also crucial for adhesion. For this reason, the applicator was equipped with a sponge that presses the label firmly onto the surface immediately after application.

Pallets with a wide variety of MDF boards are now on their way to construction sites and furniture factories. Reliably labelled thanks to label applicator-robot collaboration.