Barcode labels - "Zebra crossings" for industry, logistics and retail

They are everywhere, but only a few people know exactly what they mean. They can be found on practically every packaged product: the strange ‘zebra stripes’ with their cryptic column of numbers at the bottom. However, the barcode is an extremely inexpensive and practical means of being able to uniquely label a product with meta data. The barcode was invented as early as 1959. It took until 1973 for it to be launched on the US market.

The simple and inexpensive implementation of barcodes has led to their widespread use as a standard. This has not changed to this day.

What are barcode labels?

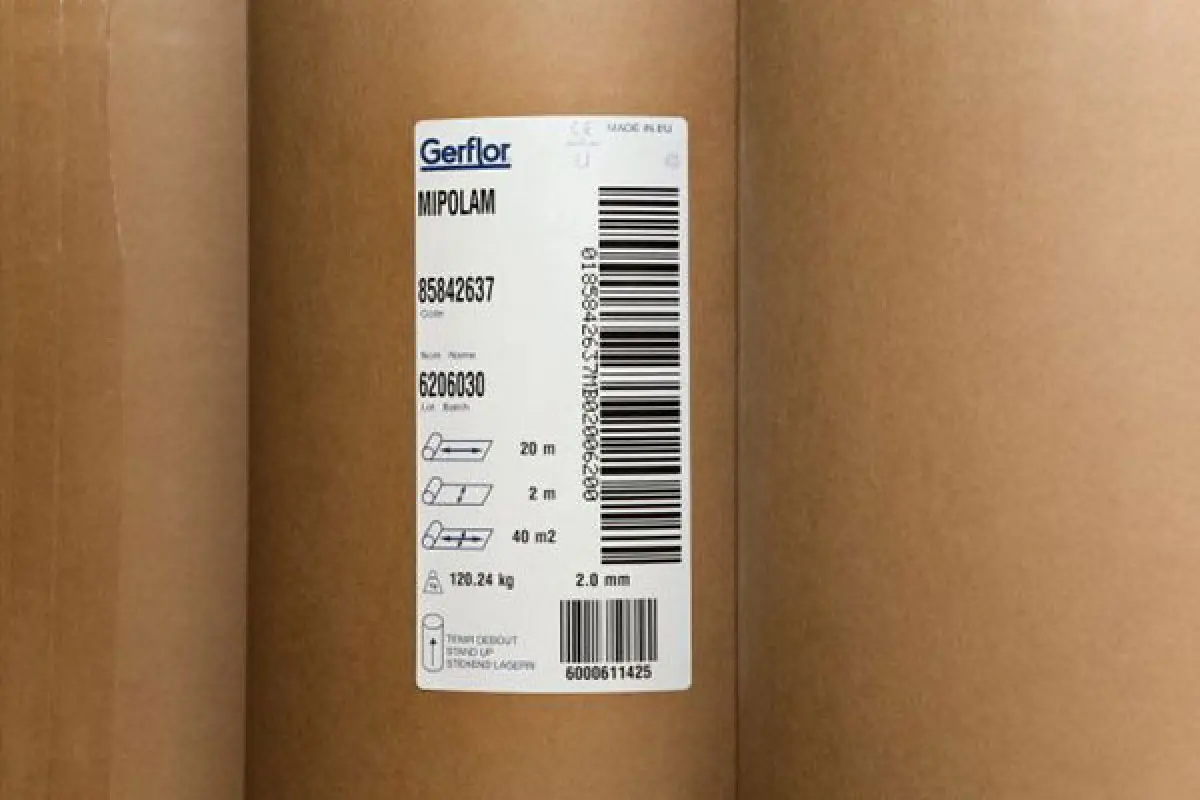

A distinction is made between barcodes that are printed on the packaging and those that are attached to the goods by means of an adhesive label. Technically, they have the same meaning: the unique identification of the goods with the output of important metadata. The advantage of adhesive labels over fixed printed barcodes is that they can be individually adapted to the respective product. This means that important metadata, such as the best-before date, can be customised.

Barcodes are identified using optical reading devices. In the past, a laser was used as standard for this. Today, digital cameras, even those in smartphones, can be used to read a barcode.

A more advanced version of the barcode is the QR code. Like the barcode, information can be added directly to the code. In addition, QR codes are usually linked to websites. By linking to a website, the product can be provided with practically any amount of information. All that is needed to read the code is a smartphone with a QR code reader.

How do barcode labels work?

Barcode labels are designed in advance and the desired information is added. The information is encrypted using the spacing, quantity and width of the bars. Barcode labels are printed on simple thermal paper. This makes the printing presses very handy and easy to maintain.

Once the label has been stuck on the product or product packaging, the goods are clearly labelled. When the label is read, exactly the same information that was previously entered in the barcode is provided. Barcode labels are practically everywhere in the world of merchandise management.

Advantages of barcode labels

The advantage of barcode labels is their high reliability and extremely simple implementation. Printing on thermal paper labels only takes a few seconds. The broad design of the barcodes also makes them very tolerant of scratches and contamination. As long as a small, continuous area can be seen at right angles to the direction of the bars, the information can be read in full.

In this respect, barcodes are even superior to the more modern QR codes.

Disadvantages of barcode labels

The only disadvantage of barcode labels is their limited information density. If the user is to be provided with comprehensive information on an adhesive label, QR codes are recommended.

In contrast to RFID chips, barcodes are purely passive. They do not respond to ‘call-up’ and require optical contact to release the information.

Product traceability using EAN on barcode labels:

The traceability of goods - for example using barcode labels - is of central importance for the efficient control of product recalls. This also regulates the traceability from the pre-supplier to the outlet. In recent years, it has become apparent that in the event of product recalls in crisis situations, targeted and cross-company tracking and return of the affected products must be more strongly guaranteed. Existing identification and communication tools are used for this purpose to quickly locate and return defective products, thus preventing unintentional and avoidable use and thereby limiting the damage.

With the achievement of cross-company product tracking, the conditions for controlling and implementing product recalls are created for all parties involved.

The resulting benefits can be described as follows:

- The parties involved in the process have access to information about the flow of goods up to the point of sale.

- In the event of a product recall, only the product or product line in question can be specifically removed from all stages of the supply chain.

- Consumer protection through preventive measures, which are intended to prevent the distribution of a ‘defective’ product to the consumer

- Avoiding a loss of image, which can occur due to a product recall.

This is now guaranteed by the EAN128 number on the barcode labels.

More information about the barcode label

EAN, a closed system for open applications

EAN has become a global standard for identification procedures. Only the worldwide freedom from overlapping of the numbering systems opens up the cosmopolitan application for everyone. At its core, this ‘EAN standard’ today consists of the big three numbering and coding systems, the International Location Number (ILN), the International Article Number (EAN), the Shipping Unit Number (NVE).

ILN

The 13-digit International Location Number (ILN) identifies physical and functional companies and company divisions. The ILN has a standardised format and its structure allows each location number to be clearly and unmistakably identified worldwide.

EAN

The 13-digit EAN number and the EAN barcode are used to identify items and goods from any source (consumer and retail units) across companies. The EAN is used exclusively for identification. It is not used for classification purposes and does not contain any descriptive information. Today, approximately 250,000 companies are involved in the EAN system through an international network of 59 numbering organisations representing 65 countries. The International Article Numbering (EAN) and the associated barcoding system, in conjunction with the American UPC solution, are a globally recognised standard.

SSCC (Serial Shipping Container Code)

The SSCC was developed as a uniform means of identifying individual transport containers. It supports workflows in the delivery, distribution and goods receiving of non-standardised packaging. As a pure identifier, the NVE, like the EAN, is an access criterion for the information behind it. In contrast to the EAN, which is assigned to specific items, the NVE does not allow any direct conclusions to be drawn about the items it contains. The 18-digit NVE is at the heart of the EAN128.

The advantages of the EAN128 on barcode labels:

- Transparent tracking from sender to recipient.

- Optimised processes for shippers and freight forwarders in the consolidated cargo sector.

- The EAN 128 barcode can store more data than conventional barcodes.

- Avoidance of reading errors.

- Completeness and excess quantity control.

- Additional control characters can be added to the barcode (e.g. order or contract numbers, expiry dates, batch sizes).

Structure of the EAN128:

According to the international EAN 128 concept, more than 40 different data elements can already be displayed in barcode form on a barcode label. They are subdivided into the following application areas:

- identification (e.g. EAN, NVE) goods tracking (e.g. NVE, lot/batch number)

- dates (e.g. production date, expiry date)

- Units of measurement (e.g. weight in kilograms)

- Referencing (e.g. order of the goods recipient)

- Company ID (e.g. company ID of the goods recipient)

- Internal applications

Dimensions of the EAN 128

The physical length, including light zones, must not exceed 165 mm.

Including the data designators, a maximum of 48 user data characters may be encoded. Including all auxiliary characters and the symbol check character, an EAN128 barcode symbol should not exceed 35 symbol characters. Otherwise, there is a risk that the magnification factor to be selected for cross-company applications will be too large. The quality of the barcode labels plays an important role here.

Maximum length: 165 mm

Minimum Bar Height: 32mm

Maximum user data characters: 48

Maximum characters in a single symbol: 35