Barcode scanner

A barcode scanner (also known as a handheld terminal) is an indispensable tool for accurately and quickly capturing and decoding barcodes. These devices use optical technologies to read the data embedded in the barcodes and transfer it into machine-readable form.

Barcode scanners have become indispensable in a number of industries, particularly in logistics, retail, industrial goods and warehousing, as they enable fast, error-free and automated data capture.

The technology is usually based on optical readers and uses different scanning techniques, depending on the type of barcode and the requirements of the respective application.

Technological principles of barcode scanners

Barcode scanners work on the basis of optical and electromagnetic principles that make it possible to read the information encrypted in barcodes. There are several scanning technologies, each tailored to different needs and applications:

Laser-based scanners

These scanners use a laser beam that is focused on the barcode. The laser beam is absorbed by the dark bars of the code and reflected by the light spaces. The reflected beam of light is then picked up by a photodetector and converted into digital data. Laser scanners are particularly suitable for reading 1D barcodes, which are mainly used in logistics and retail.

Imager scanners (2D scanners)

Unlike laser scanners, which only perform linear scanning, 2D scanners (or imagers) use a digital camera to capture the entire image of a barcode. These scanners are able to read both 1D and 2D barcodes (such as QR codes) and offer greater flexibility. They are particularly useful in applications where complex information such as URLs, product numbers or even multimedia data is encoded in a barcode.

CCD (Charge-Coupled Device) scanner

The CCD scanner uses an array of photosensitive diodes that convert reflected light intensity from a barcode into digital signals. CCD scanners are particularly advantageous in environments that require robust performance because they work without moving parts. However, these scanners can only be used effectively at relatively short distances.

Function and applications of barcode scanners

Barcode scanners are used in a wide range of industry-based applications where fast and error-free data capture is required. They are used in everything from warehousing and retail to product tracking and logistics. Some of the key areas of use include:

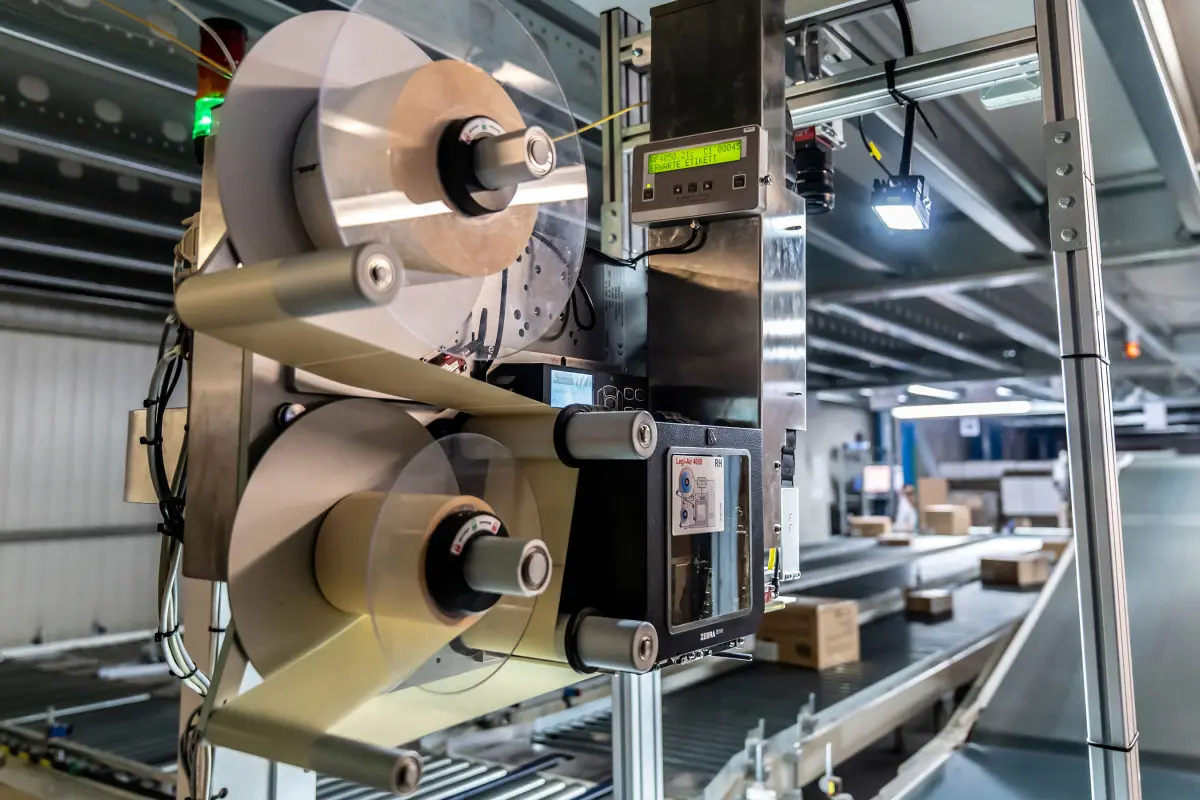

Barcode scanners for logistics and supply chain management

In logistics and supply chain management, barcode scanners enable the efficient tracking and documentation of goods and deliveries. This reduces the error rate and optimises inventory management. In particular, barcode scanners are used in large warehouses and in order picking to quickly and accurately identify items before they are packed and shipped.

Barcode scanners for retail and point of sale

Barcode scanners are an indispensable tool in the retail industry. They enable quick product identification at the checkout and simplify real-time inventory. Barcodes on products make it possible to instantly retrieve information such as price, product description and availability, resulting in efficient and error-free checkout.

Barcode scanners for warehouse inventory and inventory management

For a precise and regular warehouse inventory, barcode scanners are crucial. They enable the automated recording of goods and materials relevant for warehousing and facilitate inventory control. This reduces administrative effort and minimises human error.

Barcode scanners for production and manufacturing

In the manufacturing and mechanical engineering industries, barcode scanners enable the precise identification of components and products. By linking barcodes to production data, companies can optimise the manufacturing process, track production flow and improve quality assurance.

Barcode scanners for medical facilities and healthcare

In medical and healthcare, barcode scanners are used to manage patient data, medication administration and laboratory diagnostics. Barcodes enable accurate and rapid identification of patients, medications and tests, minimising the risk of errors in medical care.

Technical advantages and innovations of barcode scanners

Increased precision and speed

Barcode scanners enable fast and error-free data collection, which optimises and accelerates the entire production and logistics process. They help to minimise human error and increase efficiency in inventory and product identification.

Extended compatibility

Modern barcode scanners support a wide range of barcode formats, including 1D barcodes (e.g. Code 128, EAN-13) and 2D barcodes (e.g. QR codes, DataMatrix). This versatility allows them to be used in a variety of industries and offers companies the opportunity to make their systems flexible and future-proof.

Robustness and reliability

Many barcode scanners are specially designed for use in challenging conditions, such as in manufacturing, logistics or medical facilities, where impact-resistant and dust-proof devices are required. The use of barcode scanners reduces the likelihood of errors and failures in a wide range of applications.

Integration in automated systems

Barcode scanners can be easily integrated in automated systems and databases. This enables seamless data capture and fast processing of the information in real time, which is particularly advantageous in industry and supply chain management.

Outlook and future developments

The continuous further development of barcode scanner technology is being driven by the increasing integration of 2D barcode scanners, RFID technology and mobile networking. In the future, barcode scanners are also expected to be increasingly integrated into smartphones and wearable devices, further reducing costs for businesses and increasing flexibility.

In addition, advanced cloud computing technologies enable real-time processing and storage of scanned data, further improving efficiency in data analysis and data management.