Direct marking systems

Direct marking systems mark the product directly, using a laser or ink.

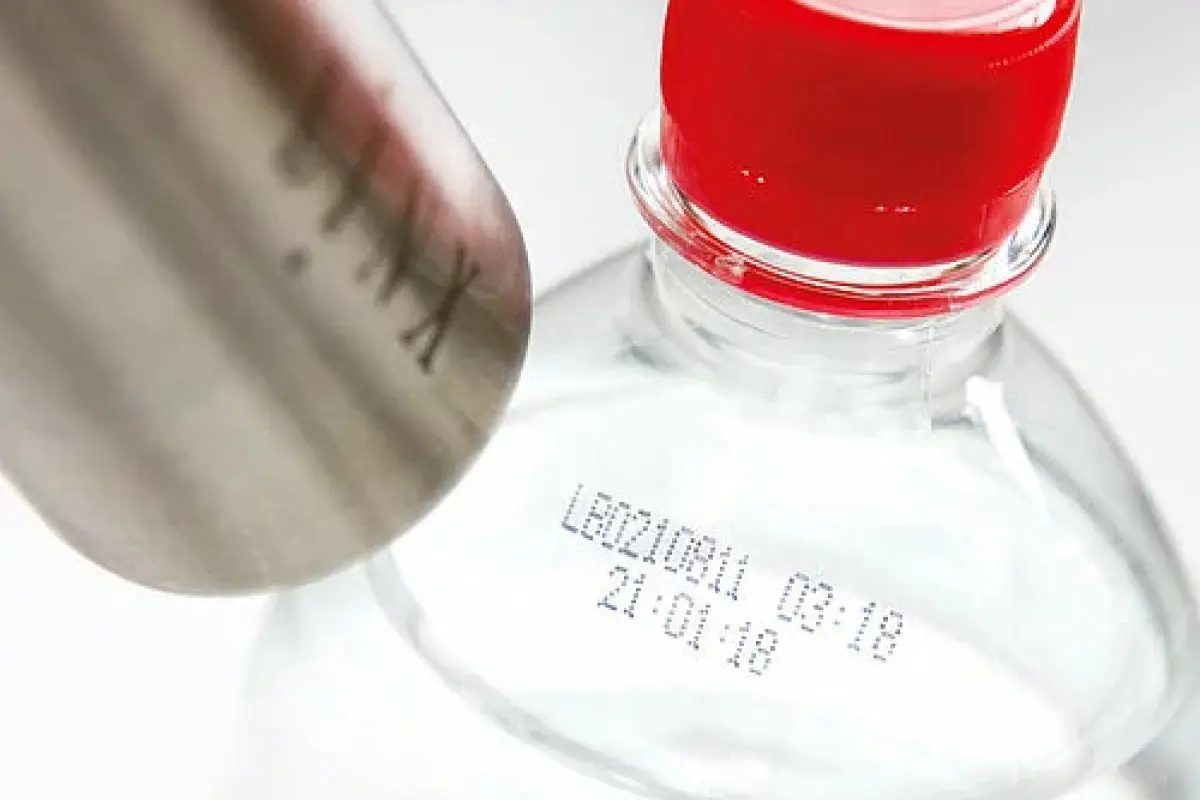

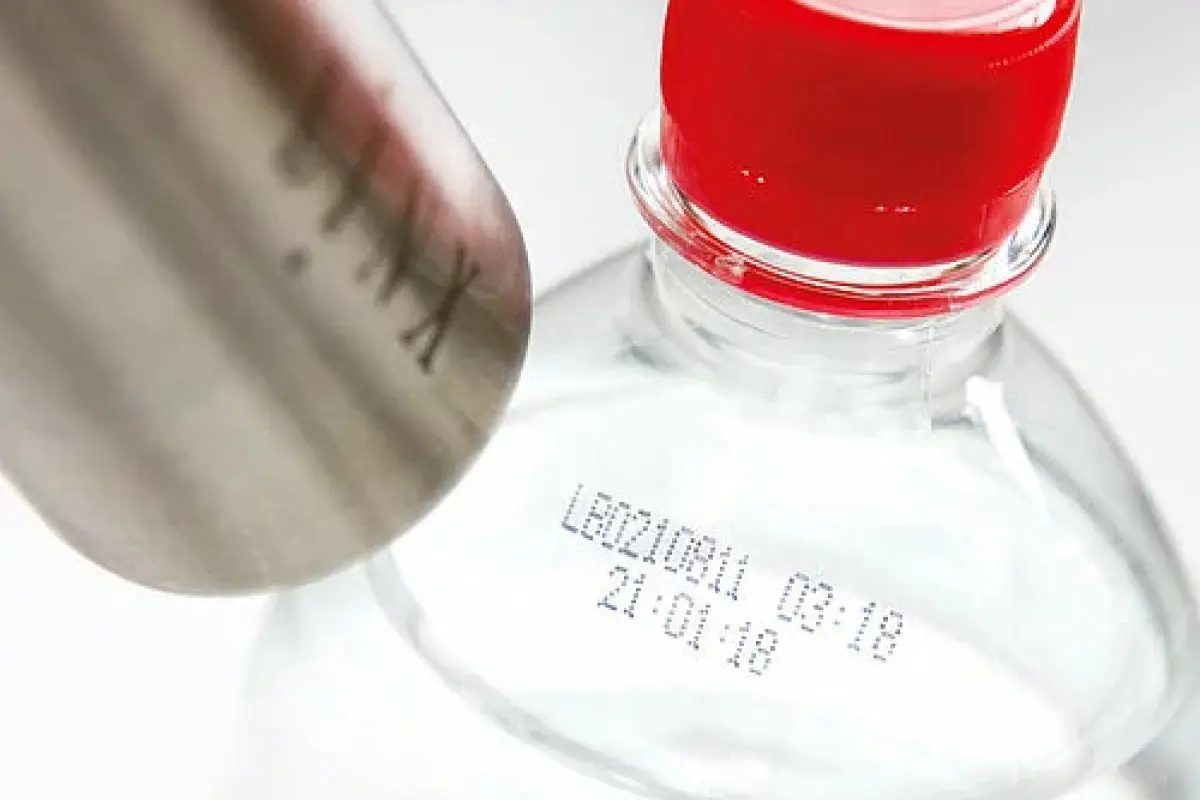

Example of direct marking on a bottle. The print head does not touch the bottle.

You have currently selected the following location:

Now switch to the following location:

oding systems are used in industry to mark products. Every product that is manufactured in the EU must be coded/labelled in some way, from the colourful labels on jam jars to the best-before dates on food.

Depending on what you are producing and what your production environment looks like, you will need a suitable coding system. Which system is used depends, among other things, on:

Different marking systems are required for different types of marking. These are divided into direct and indirect marking systems.

Direct marking systems mark the product directly, using a laser or ink.

Example of direct marking on a bottle. The print head does not touch the bottle.

In an indirect marking system, a label is printed first and then applied to the product. There are fully automatic and semi-automatic systems for printing and applying the labels.

Here is an example of indirect marking. The label is printed and then automatically applied to the product.