Security labels

Security labels have difficult-to-reproduce, sometimes invisible security features, such as

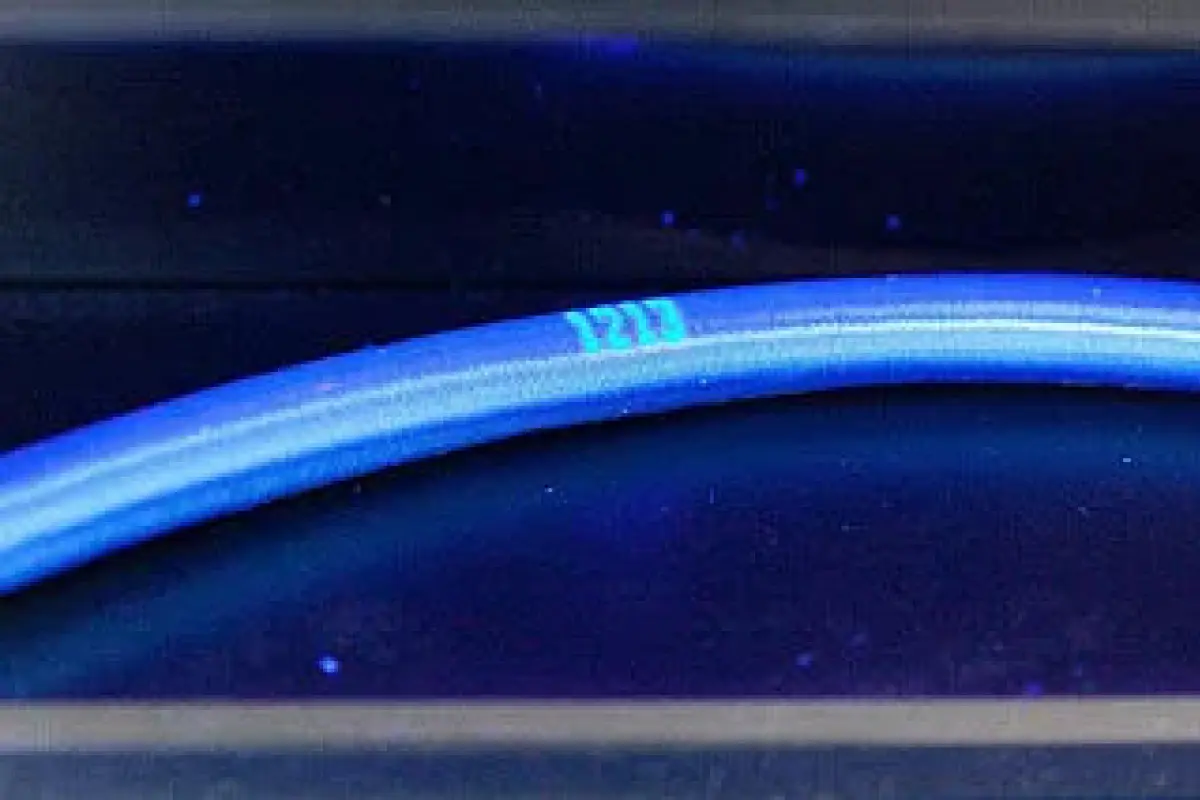

- integrated electromagnetic microwires that can be detected by special readers

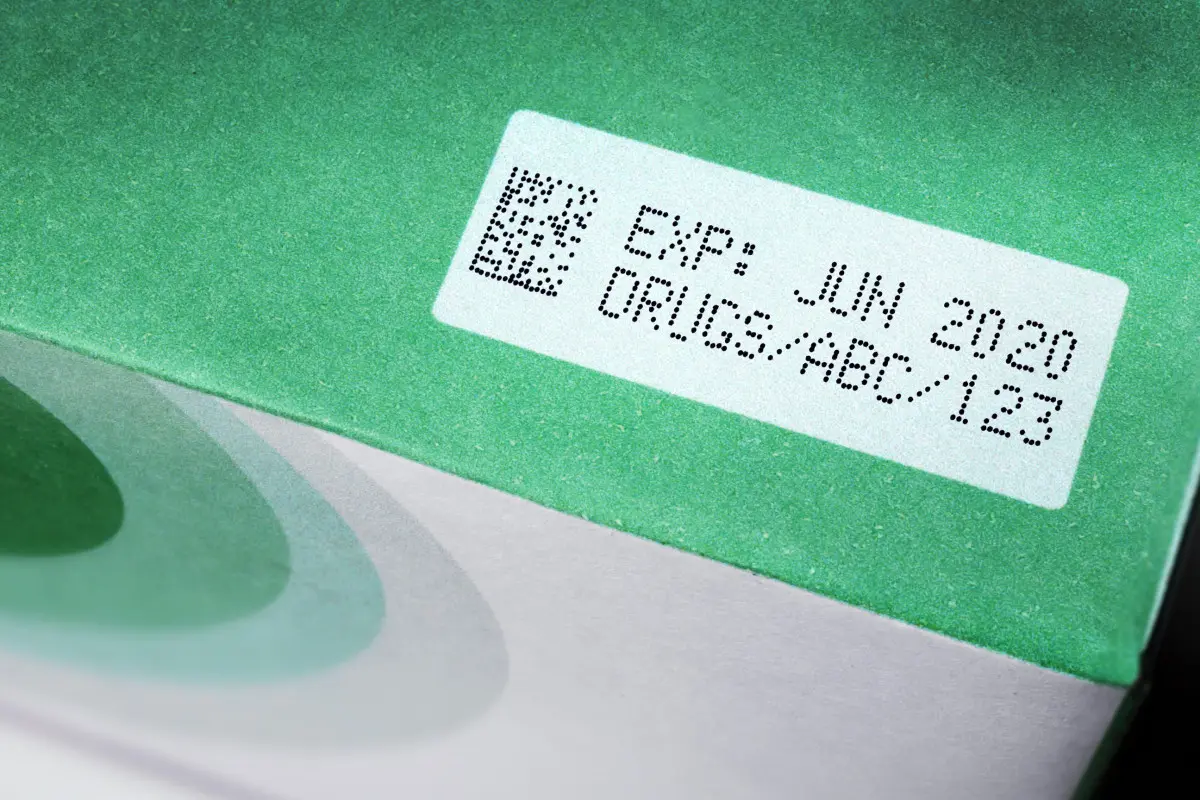

- components hidden in the label material that only become visible under UV or laser light

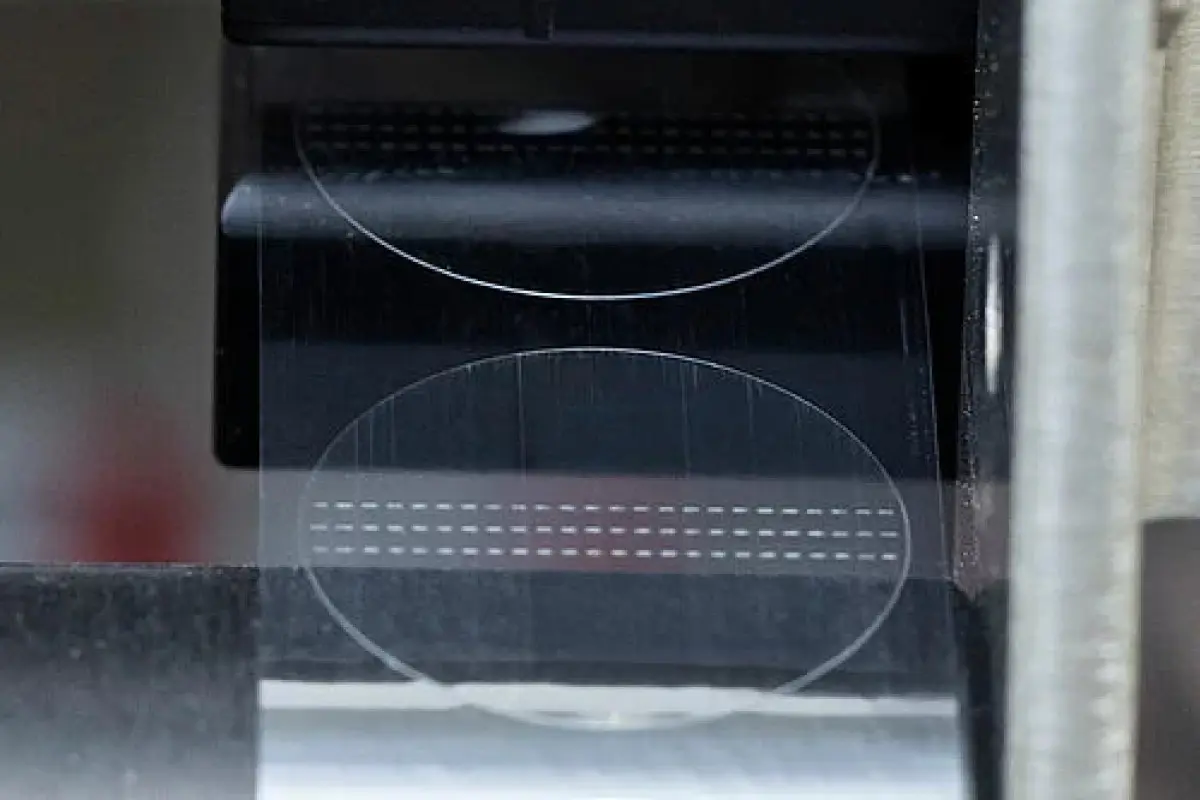

- elements created by printing technology, such as holograms or colours with a colour-shifting effect

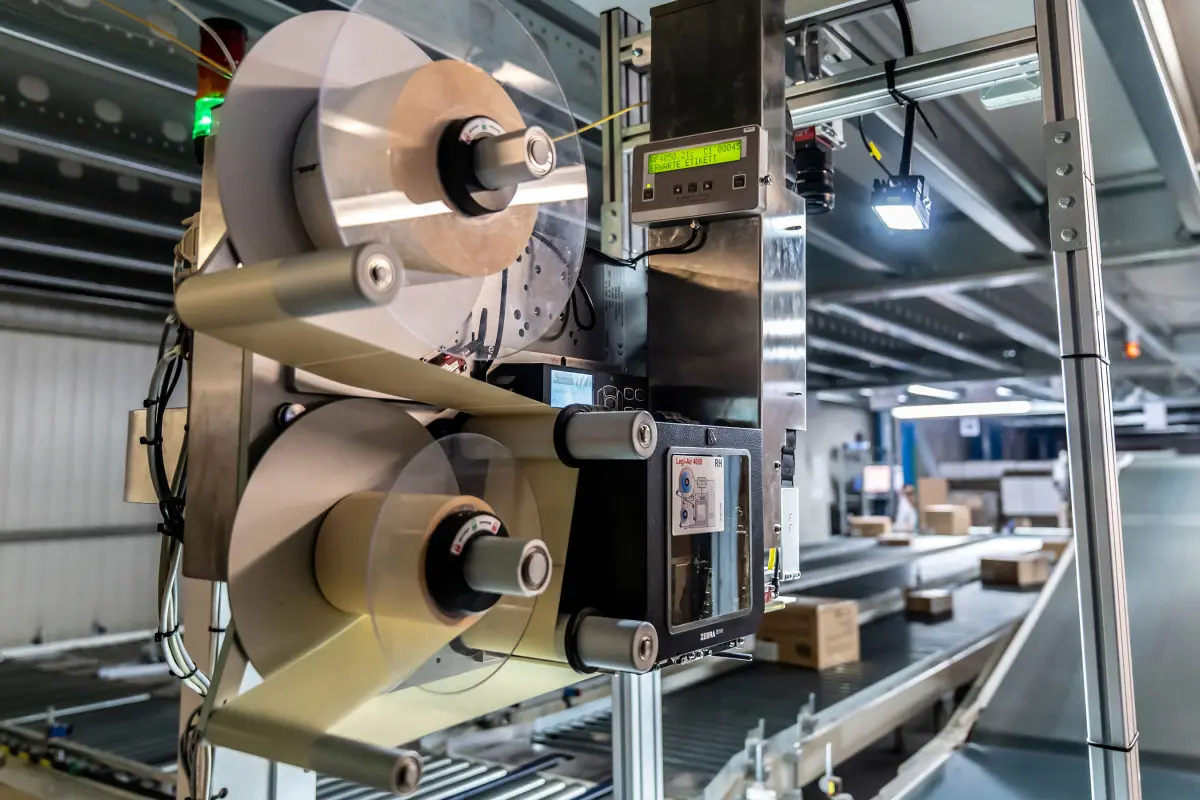

In addition, the labels can be printed with encrypted variable information at a later stage to create another barrier.