Datamatrix

The Datamatrix code is an advanced 2D code that stores information in a compact square or rectangular area as a pattern of dots. Its ability to accommodate extensive data in the smallest of spaces makes it particularly interesting for industrial applications. Unlike one-dimensional barcodes (1D codes), which are based on the width and sequence of bars, the data matrix code uses a pattern of dots that is significantly more robust and versatile.

Technical properties of the data matrix code

Structure and composition

The data matrix code consists of an arrangement of equally sized dots or squares arranged in a matrix structure.

The matrix is surrounded by a border pattern (also called a finder pattern) that allows for quick and precise localisation of the code. Within the matrix, the dots are either black or white squares or round dots, with a fixed distance between the elements.

Search pattern and decoding

The code's border contains a specific search pattern that ensures reliable reading even in the event of partial damage or distortion. The uniform symbol size and fixed symbol spacing simplify and accelerate reading and decoding.

Error correction

The data matrix code supports Reed-Solomon error correction (ECC 200), which can correct up to 25% of data losses due to damage or contamination. This error correction capability makes the data matrix code more robust than traditional barcodes, which only provide error detection.

Advantages of the data matrix code

Compact data encoding

The data matrix code can be applied to very small surfaces and is therefore ideal for small parts, electronic components or medical products. Its high data density allows extensive information such as serial numbers, production data or batch numbers to be stored.

High reading reliability

The uniform structure and integrated error correction make reading more secure, even under difficult conditions such as reflection, contamination or physical damage. The coding is independent of orientation, so the code can be read from any direction.

Flexibility and versatility

The data matrix code can be used on a variety of materials and surfaces, from paper to metal and plastic. It is suitable for printing on labels as well as for direct labelling using laser or inkjet technology.

Fields of application for the data matrix code

Production and logistics

The data matrix code is a standard in industrial manufacturing and is frequently used for product labelling and traceability.

Direct laser marking enables permanent marking that remains legible even under adverse conditions.

Electronics and automotive industry

In the electronics industry, the code is used on microchips and small components to store serial numbers and technical specifications. In the automotive industry, the code supports parts tracking and helps to make production processes efficient.

Medicine and pharmacy

In medical technology, the data matrix code is used to identify implants, syringes and other medical devices. In pharmaceuticals, it is used for product tracking and to comply with anti-counterfeiting standards in accordance with international norms such as the UDI guideline.

Datamatrix direct coding

Direct coding using laser marking or inkjet technology is an effective method for permanent and abrasion-resistant product labelling. These processes enable the direct marking of components and packaging without additional labels.

Advantages of direct coding

- High durability: the code remains legible under extreme conditions such as high temperatures, chemical exposure or mechanical abrasion.

- Cost efficiency: Eliminating labels reduces material costs and environmental impact.

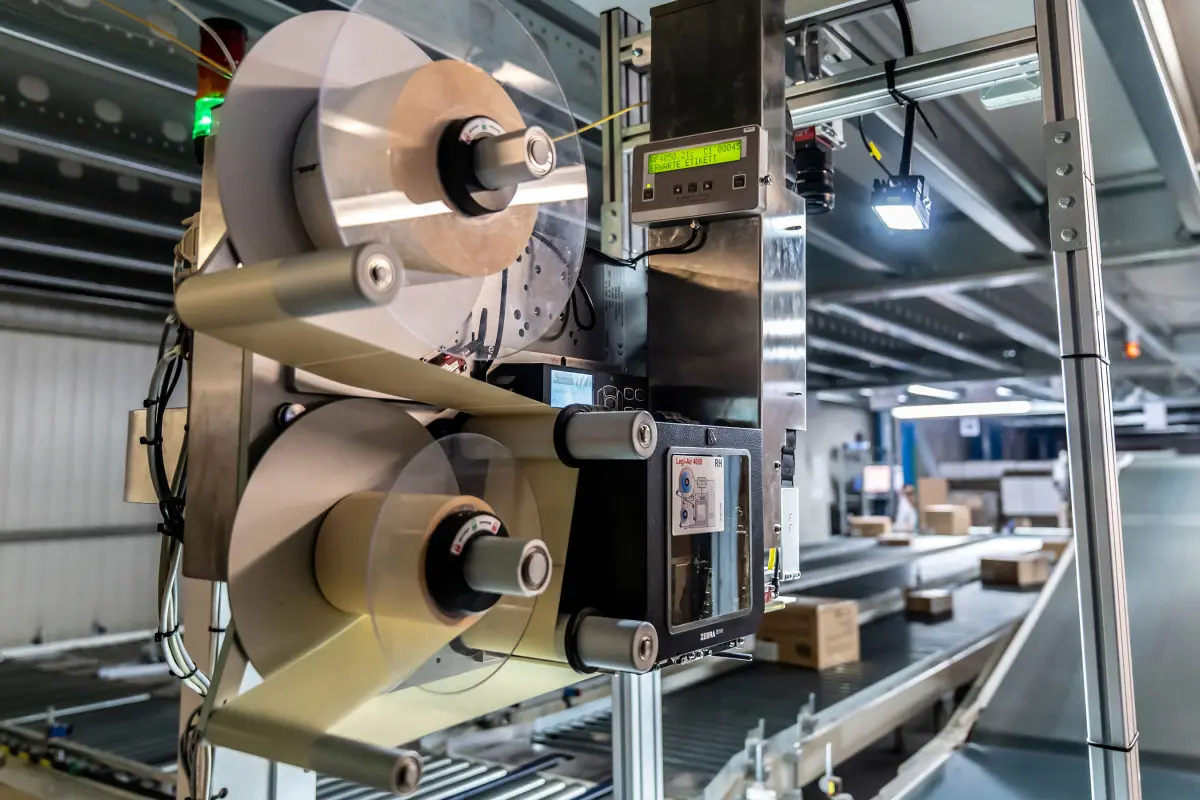

Datamatrix label printing

For applications where direct coding is not possible, printing labels with Datamatrix codes is an option. These labels can be designed flexibly and easily applied to products or packaging.

Areas of application for Datamatrix labels

Warehouse management: Marking of stock for efficient inventory control.

Shipping logistics: Use on shipping labels to track deliveries.

Packaging labelling: Integration into smart packaging solutions to interact with consumers.

Conclusion: the future of the data matrix code

The data matrix code is an indispensable tool for modern labelling technology. Its compact design, high reading reliability and error correction capability make it the preferred choice in many industries. With the advance of digitalisation and the increasing importance of traceability and data security, the data matrix code will continue to play a central role.