What are drop-on-demand systems?

Drop-on-demand (DoD) systems are a specialised technology within the inkjet printing process in which ink droplets are produced on demand - i.e. "on call" - and applied to the print medium. This technology is particularly suitable for applications that require precision and flexibility in ink delivery, such as labelling, packaging printing or product marking.

How Drop-on-Demand works

The basic idea of the Drop-on-Demand method is that the ink in the printhead cartridge is heated by thermal energy to a high evaporation temperature. This process leads to the formation of a vapour bubble that expands rapidly, forcing a tiny drop of ink through the printhead nozzle. This drop is then ejected in a controlled and precise manner onto the substrate, which can be paper, plastic, metal or glass.

This discontinuous ink droplet formation is different from other printing technologies, such as continuous inkjet printing, where ink is applied continuously without targeted control over the printed image. The drop-on-demand process means that drops are only generated when they are needed – in line with the digital print data.

The technology behind drop-on-demand

Drop-on-demand technology is based on the precise control of ink drop delivery by individually controlling each print head. Each nozzle in the print head can be activated individually, ensuring that the drop lands precisely where it is supposed to on the print medium. This technology makes it possible to create the print image with the highest degree of accuracy, which is particularly important for applications where details and clear, clean lines are essential.

One advantage of this technique is that it is relatively easy to implement, resulting in a lower price compared to other more complex printing technologies. Since only the ink delivery is controlled as needed, there is no continuous ink production or delivery, which also reduces energy consumption and operating costs.

Advantages of drop-on-demand

There are numerous advantages to using drop-on-demand technology:

- Precision and cleanliness: Because the drops are only created when requested, there are no ink drops or splashes in unwanted places. This results in clear, clean print images and lettering that are particularly easy to read.

- Flexibility of surfaces: DoD systems can be used on a variety of surfaces – both porous materials such as paper, cardboard and wood, and on smooth surfaces such as plastics, metal or glass. This makes the technology versatile and ideal for applications that require different substrates.

- Large fonts and details: The technology enables the production of large fonts or complex graphics, as the nozzles can also be dimensioned larger to precisely dispense the required amount of ink. This makes it easy to implement large print formats and detailed designs.

- Cost-effective: The simple structure and function of drop-on-demand printheads results in a comparatively low price. This technology is particularly suitable for industrial applications where cost-efficient printing is required.

Fields of application for drop-on-demand

Drop-on-demand printing systems are used in many different industries where precise and high-quality printing results are required. The most important application areas include:

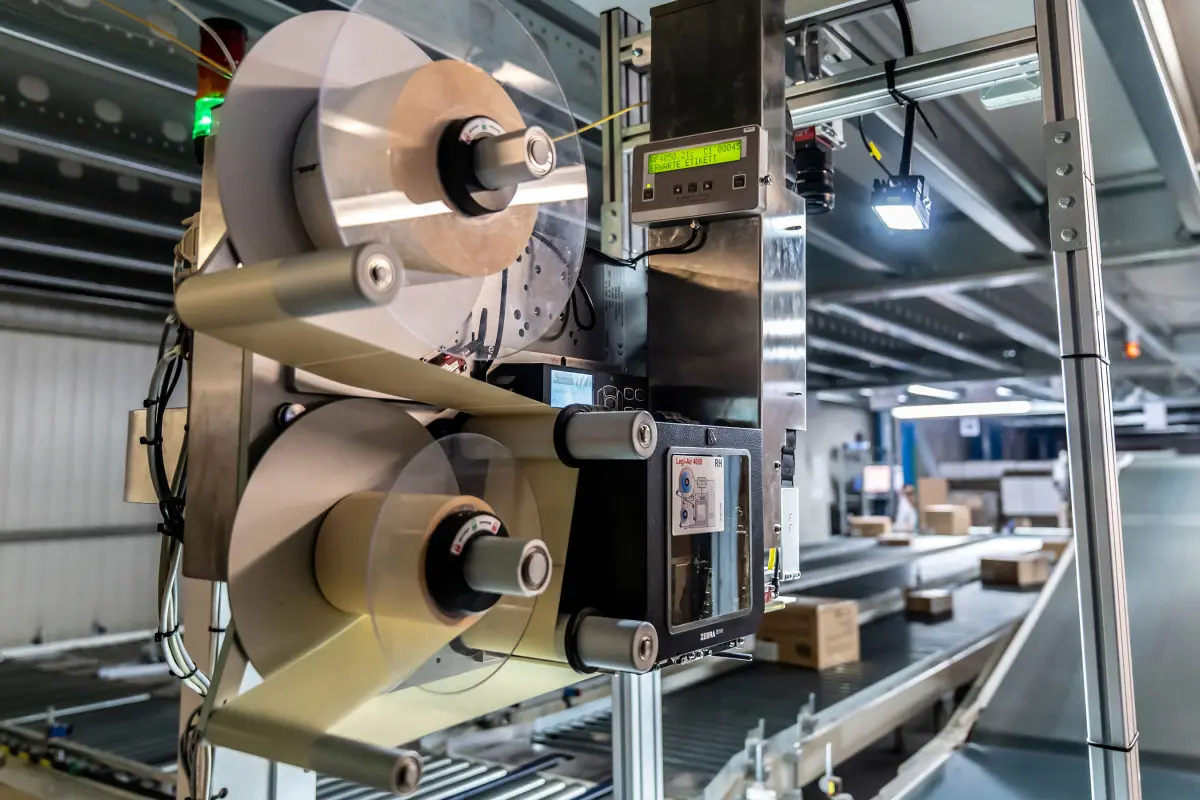

- Labelling and packaging: For labelling products in the food industry, in retail or in the pharmaceutical industry. Barcodes, serial numbers or expiry dates are printed on various packaging materials.

- Product labelling: In the automotive and electronics industries, to label products with serial numbers, logos or specifications.

- Packaging printing: on cardboard or plastic film, particularly for the production of shipping packaging, where precise and fast printing results are required.

- Textile printing: drop-on-demand technology makes it possible to print on a range of textiles, whether for personalised clothing or industrial fabric printing.

Inks for drop-on-demand systems

Another advantage of drop-on-demand systems is the versatility of the inks that can be used. Specially formulated inks are available that are suitable for both porous and non-porous surfaces:

- Porous inks: These inks are ideal for materials such as paper, cardboard or wood, as they are quickly absorbed and do not produce unwanted dripping or smearing.

- Non-porous inks: For materials such as plastics, glass or metal, where greater adhesion and a more resistant surface are required, there are specially developed inks that offer high resistance to abrasion and moisture.

Conclusion

Drop-on-demand systems are an efficient and precise printing technology that is particularly suitable for industrial applications where high quality and flexibility are required. The technology is characterised by easy implementation, cost-effective operation and the ability to work on a wide variety of surfaces and in different print formats. Whether in the packaging industry, labelling or product marking, drop-on-demand offers a reliable solution for precise print results on demand.