Direct marking systems

Direct marking systems mark the product directly, using a laser or ink.

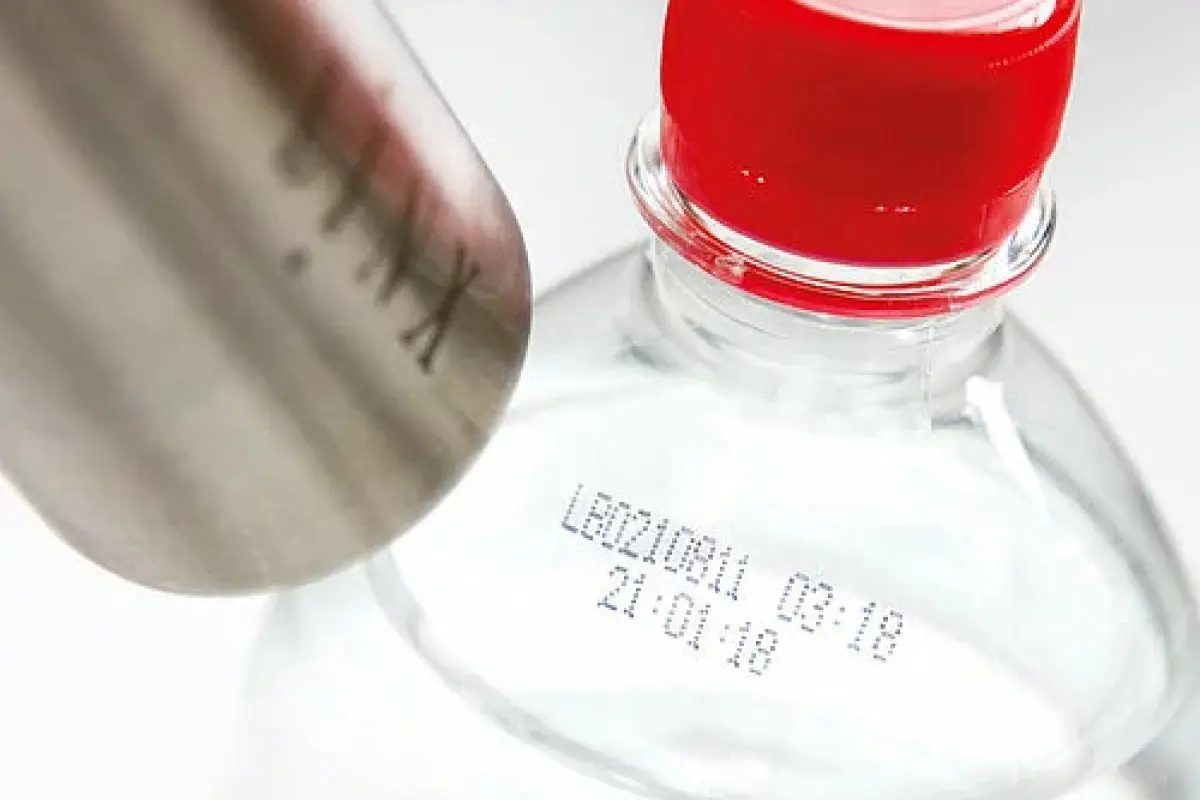

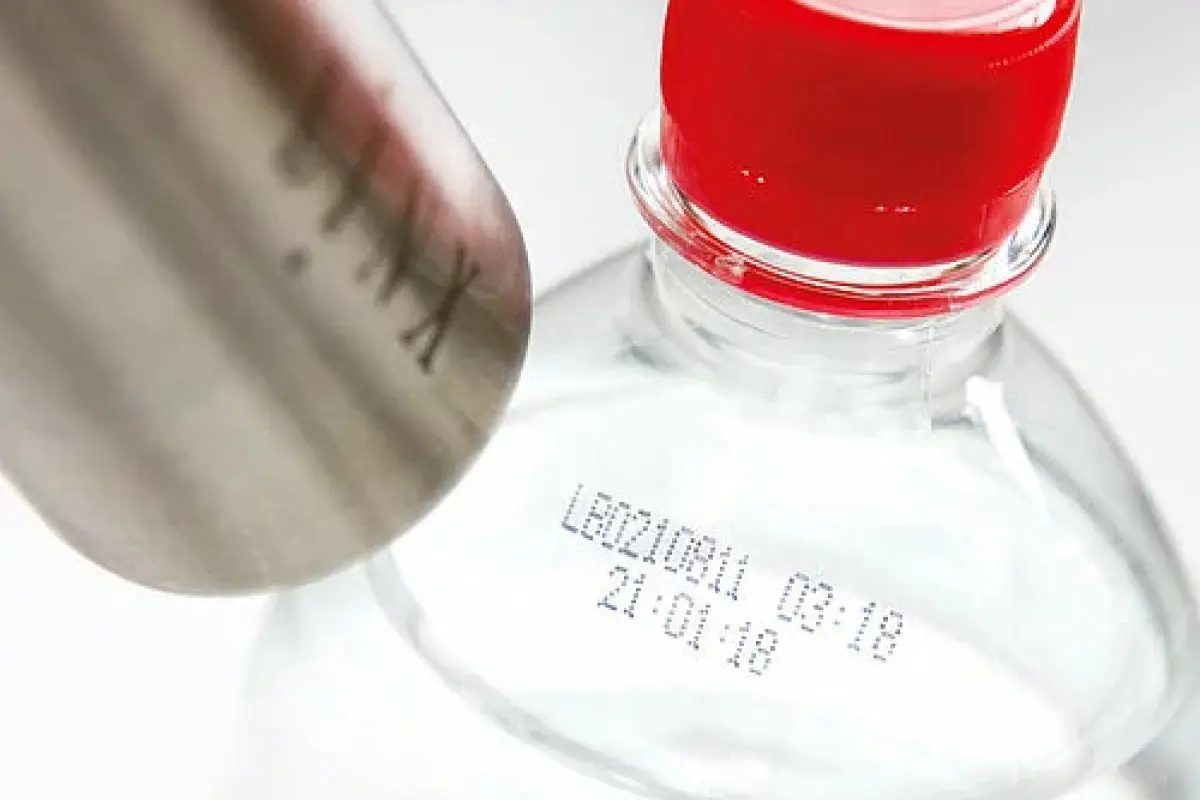

Example of direct marking on a bottle. The print head does not touch the bottle.

You have currently selected the following location:

Now switch to the following location:

The collective term ‘marking systems’ covers all industrial devices used to mark products and packaging. The machines are not only suitable for labelling the products themselves with variable information, but also their primary (product packaging) and secondary (cardboard boxes up to pallets) outer packaging.

Marking systems include not only label dispensers and print and apply systems, but also, for example inkjet printers. In contrast to office printers, these are robust, industrial-grade machines that are used across all industries, but particularly in logistics, the packaging industry and in manufacturing.

The primary task of the systems is to label products or packaging with a wide range of information such as codes, consecutive numbers, best-before dates, graphics or texts. On the one hand, this information enables the automated reading of the respective contents, the automation of logistics processes and traceability along the entire supply chain.

On the other hand, they also inform the end user at the point of sale about product contents and recommendations for use. In the case of food, there is additional important information such as lists of ingredients, allergen information, production and best-before dates, as well as storage, preparation and consumption recommendations.

Although complex codes and data can also be printed using standard printers, these printers are not suitable for use in industrial environments. This is because office printers often only print on paper in the maximum DIN A4 format, which is fed through a slot. They tend to print slowly and work with much smaller volumes of ink or toner. These devices also have limited RAM and can usually only be controlled by PCs (and not directly on the device). Furthermore, they are only suitable for use in an office environment and not in production environments where they may be exposed to moisture or dust.

By contrast, industrial marking systems score highly in a number of ways:

There are different types of marking systems. A rough distinction can be made between direct marking methods and labelling.

Direct marking methods include inkjet printing, thermal transfer direct printing and laser marking. In an industrial environment, inkjet marking is carried out either by means of the so-called drop-on-demand or continuous inkjet method.

An alternative to direct marking of products and packaging is labelling. This is suitable, for example, for applications where printing is not an option or is not practical. In addition, the use of pre-printed multi-coloured labels offers more extensive possibilities than pure (single-colour) printing or marking. Furthermore, label dispensers can apply information at variable positions and the units do not have to run over the belt at a fixed distance from the marking system.

The range of marking systems available on the market extends from entry-level devices for simple coding tasks (coding = labelling / marking) and semi-automatic systems for bottle labelling to systems that can control complete logistics processes including all peripheral devices.

For example, it is possible to start by printing labels on a label printer and applying them manually. At some point, however, manual labelling is no longer feasible. At this point, a semi-automatic entry-level system labels much faster and more accurately. As soon as the products are running on a conveyor belt anyway, labelling is another step that can be automated. Not only can goods and packaging be labelled from several sides at the same time as they pass by, they can also be printed or laser marked fully automatically.

Labelling systems are available as pure label dispensers (for pre-produced (decorative) labels) or as print and apply systems (with an additional printing module for individual labelling). It is also possible to combine a label dispenser with a system for direct labelling, such as an inkjet printer or laser marker. In this case, the direct marking devices can print best-before dates on decorative labels, for example.

Label dispensers are therefore extremely versatile in terms of their configurations and features: depending on the production environment and labelling task, they can be equipped with various print modules, dispensing strokes and applicators.

Modern marking systems: robots, camera-controlled systems and intelligent networking

The ultimate challenge in the automation of the labelling process is the use of industrial robots. When robots are used to handle parts, product labelling can be made even more flexible and efficient. Such applications are useful, for example, when a product cannot be printed or labelled immediately after its manufacture while it is on the conveyor belt, when the labelling has to be applied in variable positions or when larger distances have to be bridged. In most cases, jointed-arm robots – so-called universal robots – are used, whose movements are freely programmable.

In modern production plants, labelling machines, inkjet printers or laser markers are usually located at critical points: quality control and product packaging take place immediately before labelling. After printing, the legibility of the labelling is often checked by a scanner so that defective products can be immediately ejected. Labelling systems are therefore located between a large number of cameras, scanners and sensors.

If all these devices were networked with each other and connected to the company network, relevant key production figures could be recorded, collected and later evaluated. This data could provide answers to questions such as how many units were produced, what the (average) line speed was, how much scrap there was, how long production stood still and how often which errors occurred.

Different marking systems are required for different types of marking. These are divided into direct and indirect marking systems.

Direct marking systems mark the product directly, using a laser or ink.

Example of direct marking on a bottle. The print head does not touch the bottle.

In an indirect marking system, a label is printed first and then applied to the product. There are fully automatic and semi-automatic systems for printing and applying the labels.

Here is an example of indirect marking. The label is printed and then automatically applied to the product.