Marking technology

Marking technology encompasses all the technological solutions for the unique labelling of products. These solutions are crucial for the traceability, identification and quality assurance of products and goods. They cover a wide range of processes, from label printers to coders and modern laser systems. The continuous development of the devices ensures that labelling solutions are becoming ever faster, more precise and more cost-efficient, allowing them to be optimally integrated into the production process.

The right marking technology for your production process

Selecting the right marking technology depends largely on the specific requirements of your production process. Factors such as the type of material, production speed and the type of information to be printed play a crucial role.

Industrial Marking Technology

In modern industrial production, marking technology is indispensable. It ensures that products are clearly identifiable, which is particularly important in terms of traceability, quality management and logistics. Marking systems make it possible to efficiently print product information such as serial numbers, batch numbers, expiration dates or barcodes, which enables both the distribution and sale of industrial products. Without reliable marking technology, complex logistics and merchandise management systems would not be possible, nor would compliance with legal requirements.

Various marking methods

Modern marking technology offers a variety of processes for accurately labelling products. Some of the most common technologies include:

-

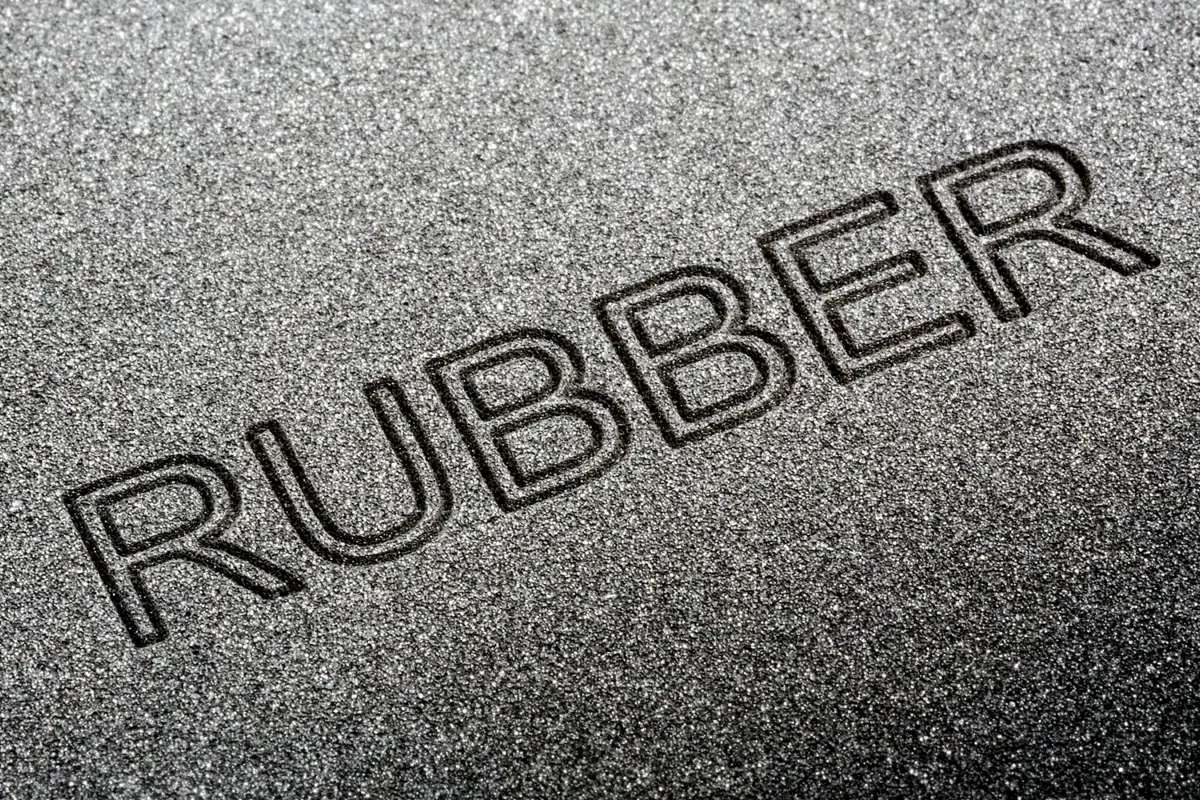

Laser marking:

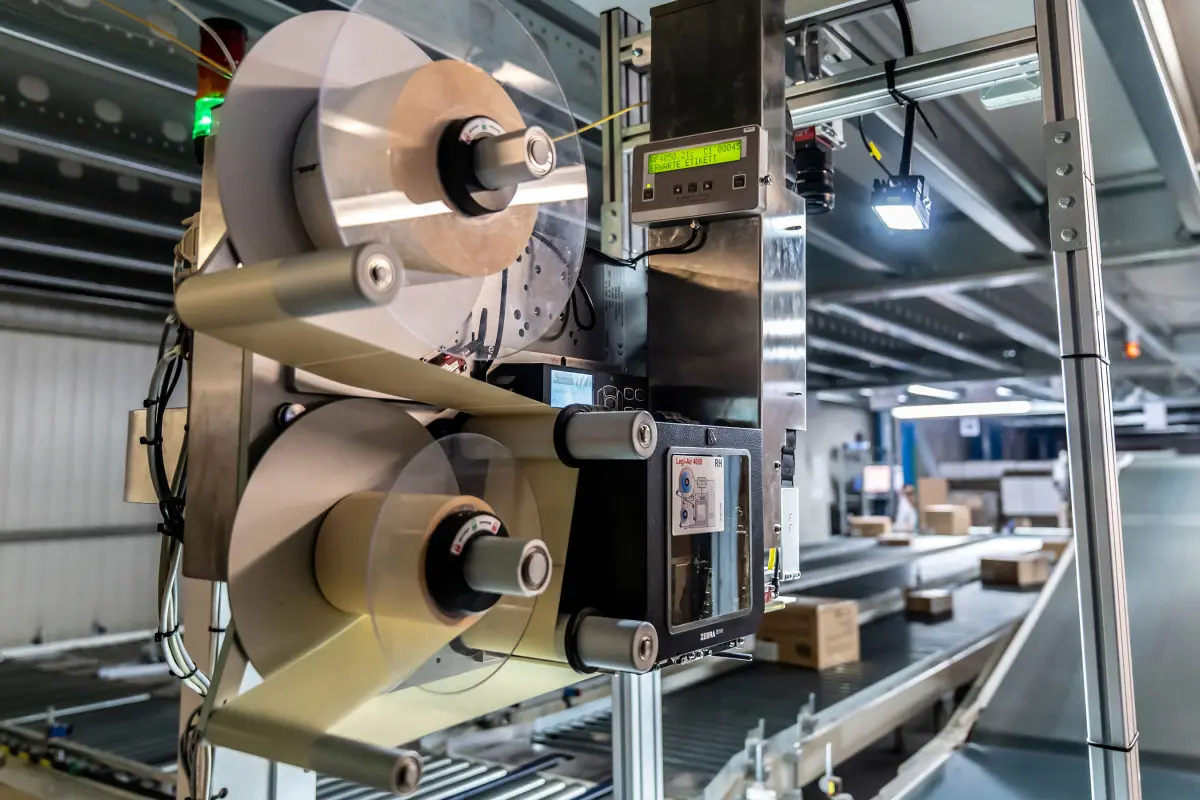

Laser marking devices offer a fast, precise and permanent solution for marking metals, plastics and other surfaces. By using fibre lasers or CO2 lasers, both engravings and writing can be produced in high quality. The method is particularly durable and is suitable for demanding environments where high resistance to abrasion and weathering is required. - Label printing systems:

Label printers are one of the most commonly used devices in marking technology. They print information on a wide variety of label materials, which are then applied to products, packaging or pallets. Modern thermal printers and thermal transfer printers guarantee high print quality and speed, which is particularly advantageous on high-speed production lines. - Inkjet printers:

Inkjet printers are another product labelling solution that can be used for both variable data and graphic markings. This technology is used primarily for printing on cartons, packaging and flexible materials. It enables cost-effective and flexible labelling, even on uneven or difficult surfaces.

Selecting the right marking technology

The choice of the optimal marking technology depends on several factors, including the type of product, the material, the printing speed and the print quality requirements. For example, laser systems are suitable for products with high durability and precision requirements, while label printers or inkjet printers may be the best choice for fast, cost-effective solutions in the packaging sector.

Summary

In today's industrial production, marking technology is indispensable for ensuring product quality and traceability. Selecting the right technology – from laser marking to label printers and inkjet printing systems – enables companies to work efficiently, accurately and cost-effectively. With the right marking solution, companies can optimise their production processes and meet legal requirements.

Interested in a solution for your labelling?

Contact us today and get advice from our experts to find the optimal marking system for your production line.