OPC Unified Architecture (OPC UA)

An open standard for data exchange in the IIoT

OPC stands for ‘Open Platform Communications’ and provides a standard for data exchange between machines and software in the field of industrial automation. The ‘Unified Architecture’ (UA) is a service-oriented architecture that integrates all OPC functions into an extensible framework. OPC-UA makes it possible to transfer machine data across platforms and independently of the manufacturer and to describe it semantically. The OPC Foundation is responsible for developing and maintaining the standard.

Significance and advantages for Industry 4.0

Digitisation and automation are the key to maximum efficiency for industrial companies. The ultimate goal of Industry 4.0 is to intelligently network processes, machines and systems and enable them to control themselves. This is referred to as the Industrial Internet of Things (IIoT). Autonomous processes become possible when the various devices and systems exchange information with each other and react accordingly. To do this, however, they must find a ‘common language’. OPC technologies provide the basis for simple, secure and reliable transfer of data across all platforms. As an open standard, OPC-UA is particularly easy for all users and manufacturers of automation technology to use. It saves time and money for seamless integration of new systems.

Areas of application for OPC-UA

OPC-UA is used wherever components such as sensors, controllers and regulators from different manufacturers are networked. It is used for the following functions:

- monitoring real-time data

- archiving data

- outputting alarm messages and notifications

- transmitting commands

Specifications

The OPC standard combines specifications that have been developed by manufacturers, end users and software developers. These specifications define the interface between clients and servers, as well as servers and servers.

First published in 1996, the standard was designed to condense PLC-specific protocols (such as Modbus, Profibus, etc.) into a standardised interface that would allow HMI/SCADA systems to connect to a ‘middle-man’ that would translate generic PLC read/write requests into device-specific applications and vice versa. This resulted in a whole range of products that allowed end users to implement systems with best-of-breed products, all of which interact seamlessly via OPC.

Initially, the OPC standard was geared towards the Windows operating system. This is how the acronym OPC was derived from OLE (Object Linking and Embedding) for Process Control. These specifications, now known as OPC Classic, have been adopted across a wide range of industries, including manufacturing, building automation, oil and gas, renewable energy and utilities.

The introduction of service-oriented architectures in manufacturing systems has created new challenges in terms of security and data structuring. The OPC Foundation developed the OPC UA specifications to meet these requirements while providing a future-proof, scalable and extensible architecture with many functions that is open to all technologies.

OPC UA, PACK ML and Weihenstephan Standards

The networking of plants and production machines with each other and with higher-level IT systems is a prerequisite for the realisation of digitalised production control. The Weihenstephan Standards (WS) simplify this networking by providing manufacturer-independent specifications for a uniform communication interface based on the client-server model. The Weihenstephan Standards Information Model is used to describe the instance of a machine profile within a WS domain. Currently, a total of over 150 different machine profiles are defined in all WS domains. To reduce the resulting complexity, the Companion Specification (CS) describes a generic meta model for all WS machine profiles. The meta model is based on OPC UA for Machinery and PackML.

Wever marking technology – future-proof and a safe investment

Markings play a key role in industrial automation: barcodes, data matrix codes or RFID chips even make products, components and packaging ‘smart’. Using Auto-ID technologies, for example, real-time operating data can be linked to individual orders. Weber Marking Systems' marking technology is equipped with all the important interfaces. This makes it particularly easy to integrate into any environment and also adapts to your future projects.

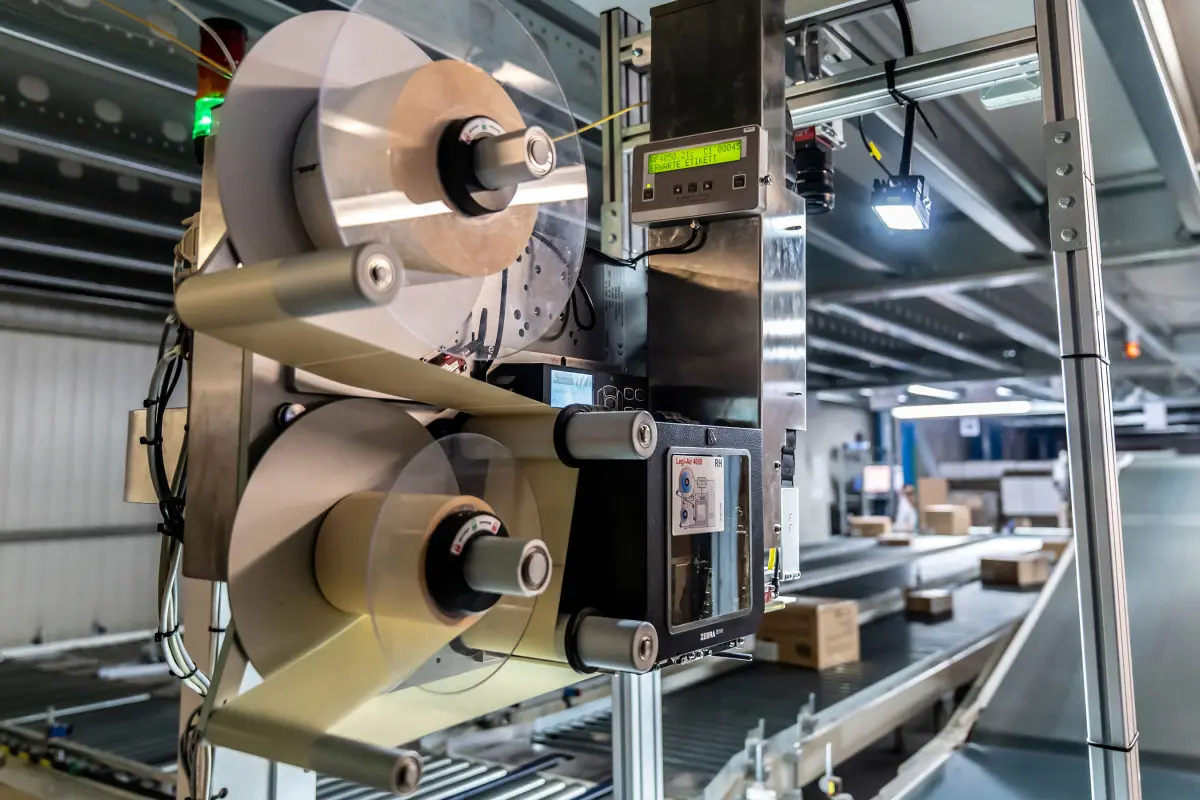

Labelling systems with OPC-UA

Weber Marking Systems also uses OPC-UA-capable labelling systems. Label printers and print and apply systems print and apply labels to the corresponding object surfaces. Since they have to adapt to all production processes and environments, they are offered as a flexible modular system.

Bluhmware software

Bluhmware is an automation software that makes complex marking processes transparent and easy to control. ‘Cockpit’ is used to organise all important data and the hardware of the marking solutions. This includes graphical production statistics, batch changes, user administration, maintenance notifications and care instructions, as well as the inventory management of consumables. Self-created print layouts and layouts are available at all times via the central database. Bluhmware can be accessed via smart devices from any location and provides information about faults, for example.