PackML

Machine language for automated processes in the packaging industry

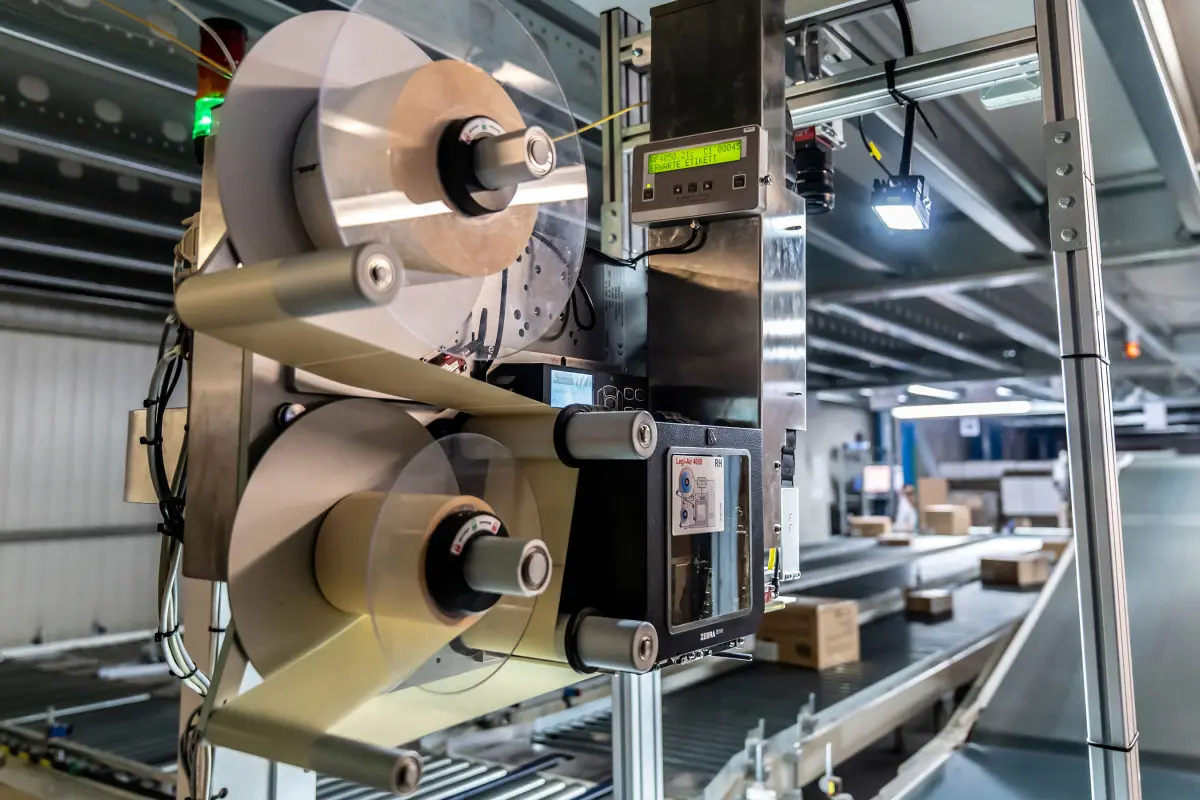

The term PackML stands for ‘Packaging Machine Language’. It is an industry standard defined by the Organization for Machine Automation and Control (OMAC) for machine-to-machine communication in the packaging industry. The standardised programming language is designed to simplify the integration, control and maintenance of machines in automated manufacturing systems.

Uniform look and feel for operators

PackML is designed to make packaging machines easier for operators to use. It simplifies integration and makes the software easier to expand and diagnose. The ISA standard TR88.00.02 defines a state machine, some modes and naming conventions for variables within the standard. This makes it possible to implement a standardised external interface, known as PackTags. The state machine defines 17 states in which the machine can be located and thus controls its sequence. Within the state machine, clearly defined structures must be adhered to when writing the machine code.

The mode manager manages the machine's operating states. These can be, for example, automatic, manual, maintenance or cleaning. However, various manufacturer-specific operating modes can be defined here. The mode manager checks whether it is possible or even allowed to switch between operating modes, depending on the machine's current state.

The PackTags are the interface to the outside world. The relevant machine data is stored here and can be used for horizontal integration (e.g. with other machines) or for vertical integration with higher-level systems (e.g. MES or ERP). They include admin, status and instruction tags. This means that machine information such as the current speed, status, operating mode and much more can be read out and the machine controlled. It also includes a comprehensive alarm management system. The PackTag interface is made accessible to the outside world via the OPC UA communication standard. The OPC Foundation has already published a corresponding companion specification. This ensures an automated exchange of data between machines from different manufacturers as part of Industry 4.0.

PACK ML, OPC-UA and Weihenstephan Standards

The networking of systems and production machines with each other and with higher-level IT systems is a prerequisite for digitalised production control. The Weihenstephan Standards (WS) simplify this networking by means of manufacturer-independent specifications for the uniform communication interface according to the client-server model. The Weihenstephan Standards Information Model is used to describe the instance of a machine profile within a WS domain. Currently, a total of over 150 different machine profiles are defined in all WS domains. To reduce the resulting complexity, the Companion Specification (CS) describes a generic meta-model for all WS machine profiles. The meta-model is based on the OPC UA for Machinery and PackML standards.