Product Marking

Packaging a product for the end consumer is always a major challenge. Just as chic clothing characterises a fashion-conscious person, visually attractive packaging enhances the contents. But in addition to the many colourful advertising promises on a package, hard facts must also be found on products and packaging. Here you can find out...

- ...what product marking is,

- ...which legal requirements must be complied with,

- ...which labelling procedures currently exist on the market,

- ...in which sectors product and goods labelling is particularly important,

- ...which different technologies are available,

- ...what challenges companies are facing in the age of Industry 4.0.

Product marking – an integral part of every production process

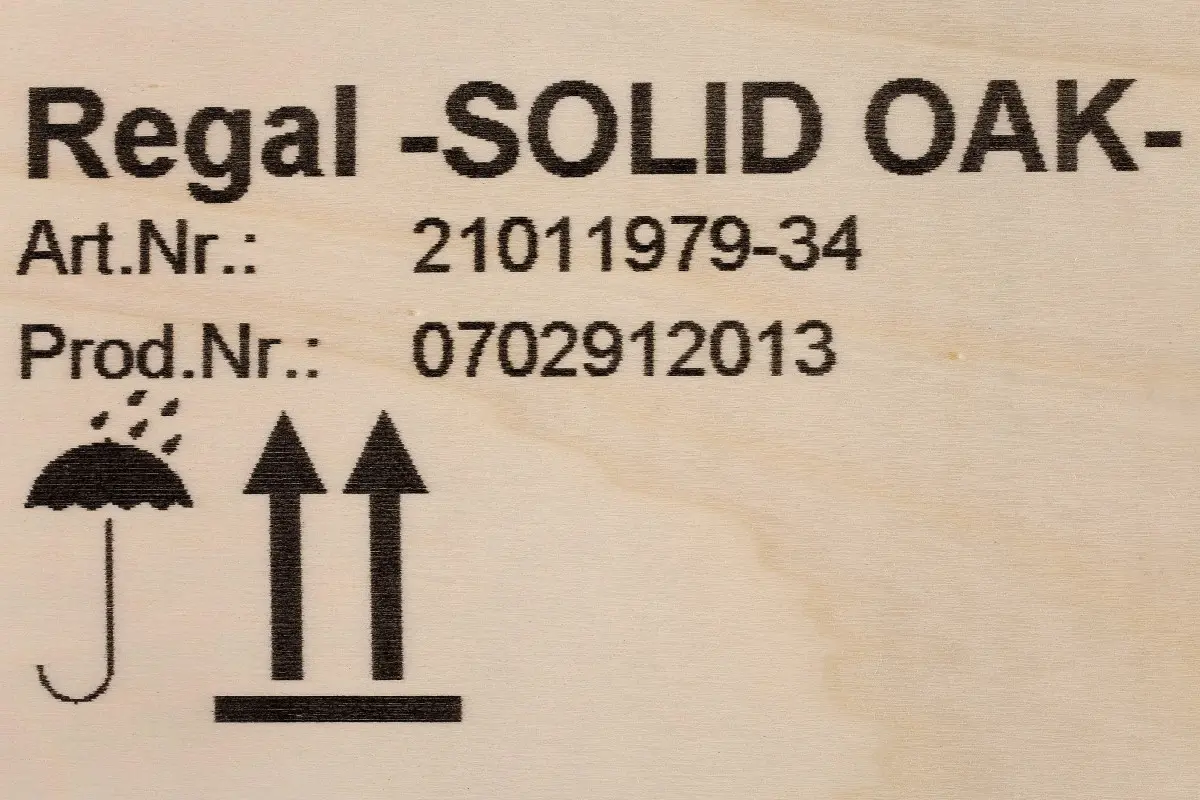

The batch number, bar or QR codes, legally required information such as lists of ingredients, ingredients or best-before dates must be on every container of food products or other perishable goods.

Non-food items must also be traceable and verifiable via clear product labelling. Clear product labelling is also very much in the interest of the manufacturer. After all, this is how they can distinguish a genuine product from a fake. This also applies to B2B packaging, which is usually much plainer. High-performance product marking must therefore have certain properties in order to reliably fulfil its purpose.

These include, for example, a simple, quick-to-read design and intuitive customisability to the respective product. Equally important is a durable hold on the product packaging – or even directly on the product. Finally, a product marking or label should also be as inexpensive as possible to produce and economical in terms of resource consumption.

All of this puts the manufacturers of marking systems under a great deal of pressure to innovate, so they regularly surprise with very innovative solutions.

Product labelling is an integral part of every production process.

In this context, practically every outer packaging or product must be labelled. From wrapped pallets to large containers and cardboard boxes for individual products, labels and direct markings provide precise information about the contents.

However, since the packaging systems differ greatly from one another, different systems are required for each packaging step. This makes the integration of continuous industrial marking in a moving production line a major challenge.

Statutory framework for product labelling

In Germany and Europe, product labelling is required by law. This legislation is primarily intended to protect consumers. However, it also has far-reaching implications for product liability and for the manufacturer's quality control.

There is no single product labelling law, but rather a large number of regulations under which the labelling requirement is divided. This is for good reason: after all, screws, for example, must be labelled differently than medicines or food. The most important legal regulations that deal with product marking are:

- Food Information Regulation

- Product Safety Act (ProdSG)

- 9th Regulation for the ProdSG - CE Machinery Directive

- Cosmetics Regulation

- Medical Devices Act - CE Directive on Medical Devices

- Textile Labelling Regulation

- EMC Act - CE Guideline for Electromagnetic Compatibility

The manufacturer is always responsible for the correct labelling of the goods and products. The retailer is exempt from the labelling requirement, but under no circumstances may they modify the labelling without authorisation. Retailers are only allowed to label prices or other marketing-related information (e.g. ‘Special offer’ or ‘New price’).

Labels are applied to the bottle using labelling systems. The label usually contains further product markings such as a barcode or a best-before date. However, the retailer must ensure that the manufacturer's product marking is not covered or destroyed.

But be careful: importers who import goods from non-EU countries are considered manufacturers by law. In the European Union, the ‘manufacturer’ is equated with the ‘distributor’.

The design of the labelling is highly diverse. Put simply, it is divided into three sections:

- All necessary consumer information

- Name and contact information of the manufacturer or importer

- All relevant markings and symbols that are used to identify the product.

In addition, the physical characteristics of the product marking are also regulated by law. Essentially, the regulation states that the product marking must be firmly affixed to the product or packaging. This means that it must not be possible for it to separate from the product either through normal handling during transport to the end user or due to weather conditions. Therefore, washable inks or labels with water-soluble glue are not permitted for mandatory information on products.

Labelling process

In the technology of product marking in a constant state of change. Three factors are crucial for the development of a labelling solution:

• Compliance with legal requirements

• Budget

• Integrability into a continuous production process

Complying with legal requirements is the easy part of labelling. Here, only the content, form and size have to be defined; the hardware and software take care of the rest. Manufacturers are already very advanced in this regard. With simple interfaces, usually touchscreens, operators can define the label content on site.

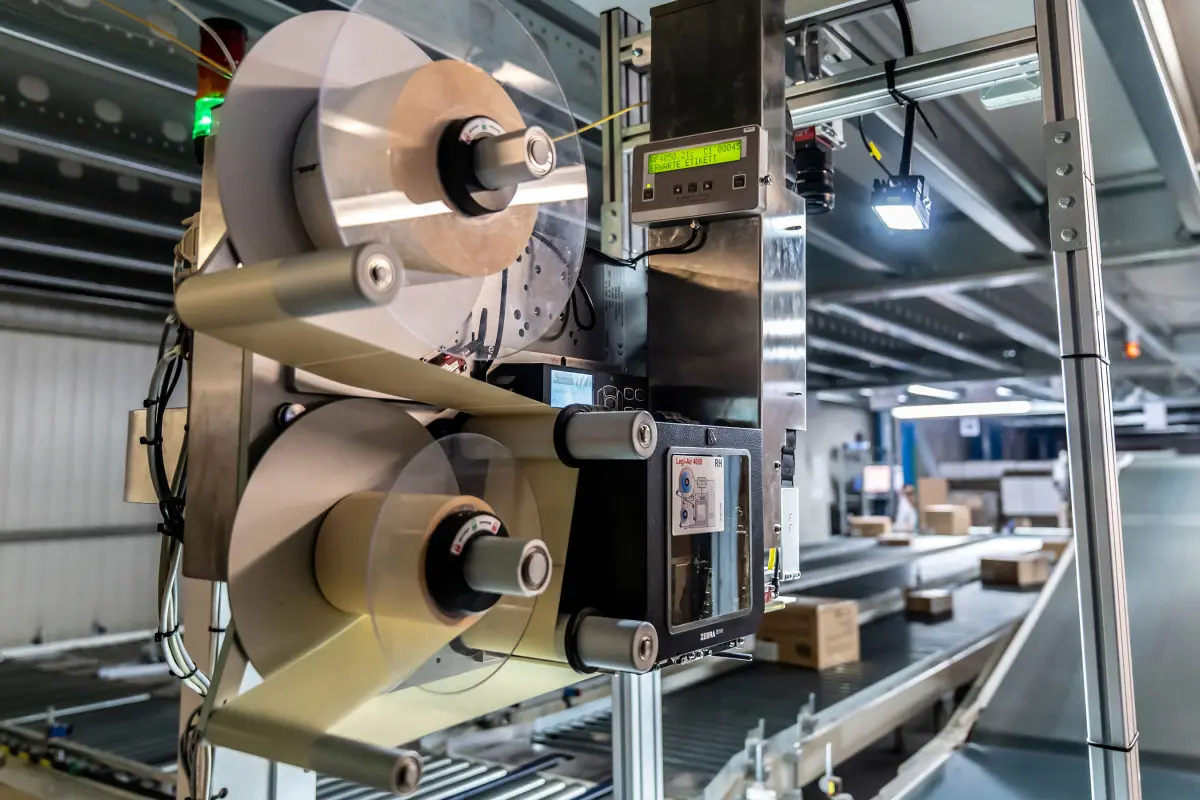

Probably the most important factor when choosing a labelling solution is its integrability into a continuous production process. It only makes economic sense if the labelling machine can keep up with the other production and packaging machines. If it slows down a production process or brings it to a halt due to frequent faults, it can jeopardise production and thus the profitability of the entire company. For this reason, labelling devices are usually extremely robust, reliable and fast.

In the labelling industry, a distinction is made between two methods of serial consecutive product labelling: direct product marking and indirect product marking.

Direct marking of products and packaging

In direct product marking, as the name suggests, the product or packaging is marked directly. This method does not require any carrier materials such as labels.

Direct product labelling is very challenging to implement: the labelling machine must be precisely aligned with the passing product. Even the slightest deviation makes the label illegible and thus unusable. As inexpensive, quick and easy as this solution is, it definitely requires a high level of quality control. However, with the help of the barcodes and QR codes used today, this is no longer a problem. Digital reading methods make it very easy to integrate controls for clean product marking into the production process. This gives the manufacturer 100% control over the legally compliant application of his product markings.

Indirect marking of products and packaging

In the case of indirect marking, the information is first applied to a carrier material, which is then attached to the product in a second step. In most cases, these are adhesive labels. However, attached labels, such as those used in the textile industry, are also possible. Although indirect marking is considerably more expensive, it also offers a number of advantages. These are:

- Removable marking

- Marking on any surface

- High marking security thanks to prefabricated labels

- Expansion of functionality

The removability of a marking is an interesting feature in many areas. In particular, customers do not want permanent product marking on textiles. Adhesive labels are also well suited for irregular or yielding packaging solutions. For example, pallets wrapped in stretch film can hardly be marked in any other way than with a large adhesive label.

The prefabricated labels practically guarantee the legally compliant marking of each product. As long as the gluing process is not disrupted, each product is reliably provided with its identification label. Errors of this kind are usually noticed immediately, so that with adhesive labels, there are usually no undetected disruptions to production. This is not the case with direct labels.

RFID radio chips in logistics

Labels can be enhanced with interesting additional features. RFID technology is one example. In recent years, a lot has been achieved with the help of these radio chips in terms of anti-theft and copy protection, as well as in the tracking of goods and packaging. Tracking via radio chips has proven to be a blessing for the entire logistics industry. The recording and tracking of a product without direct visual contact makes logistics processes much more reliable, easier and faster.

Industries with a need for product marking

Wherever physical, packaged products are sold, product marking is useful or mandatory. With the exception of bulk materials or liquid and gaseous media that are not packaged in containers, every product is marked. Even digital products that can only reach the end customer via streaming or downloads do not have to be packaged or marked. But a CD-ROM or a Blu-Ray DVD is subject to product marking requirements. This makes the demand for marking solutions extremely high. Typical industries with a high demand for marking solutions are:

- Food industry

- Pharmaceutical industry

- Consumer goods

- Consumer electronics

- Consumables (paints, varnishes, etc.)

- Appliances, tools, hardware

- Cosmetics

- Automotive industry, especially replacement and tuning parts

- And many more

Since not only the end product but also each outer package is labelled or marked, the demand for the corresponding machines multiplies. With each outer package, the surface of the material and the target group for the product marking also change. That is why different marking solutions are required in the course of a production process, from finishing to the transport-ready package.

Food industry

Find out how our customers from the food industry reliably mark their products.

Automotive industry

Find out more about our marking solutions for the automotive industry.

All industries

Find out how our customers from different industries securely label their products.

Product Marking Technologies

The need to be able to mark every physical product that can and must be marked, regardless of its nature, with a label or marking, constantly presents the product marking industry with new challenges. It is not just a matter of being able to reliably mark new materials. The principles of economic efficiency and integration into existing production processes must also be constantly taken into account.

In technical terms, marking machines must be designed to meet the following operating conditions:

- Production speed

- Environmental conditions

- Product surface characteristics

- Adaptability to the intended marking purpose

Speed of marking devices

Ideally, a marking machine, regardless of its technological orientation, is the fastest system along a production line.

If the production and packaging machines are faster than the marking machine, for example, production delays will inevitably occur. It is therefore essential to select a marking machine that can guarantee a production speed within the cycle time specified by the production machines. Labelling and printing machine manufacturers have long since responded to this requirement.

Regardless of whether the product marking is direct or indirect, the marking machine is always the fastest machine in the production process. However, it must not only be fast, but it must also be possible to adjust it individually to the respective production process. Ideally, labelling speed or printing speed, internal transport speed and production speed are synchronised. Since this is not always possible, the marking devices and the upstream packaging machines must be adjustable to the production speed of the manufacturing machines.

Dusty to humid production environments

Environmental conditions pose another challenge for labelling machines. Dusty, humid conditions, for example, make the use of self-adhesive labels very difficult. Directly printing on perishable goods with ink is also not ideal. Marking solutions in hygienically demanding environments are subject to particularly stringent requirements. A manufacturer and service provider of marking solutions is therefore prepared for each of these challenges and has the right machine for every environmental condition.

Different packaging and production steps require individual measures

A product comes out of the production machine and is produced within the given tolerances. It is then packed and placed in a box. The boxes are finally stacked on a pallet and shrink-wrapped or wrapped in film to prepare them for transport. The surface of the product to be marked changes at each production and packaging step. Smooth, high-precision workpieces, screen-printed and waxed sales cartons, outer packaging made of transport cardboard and, finally, soft, elastic and irregularly shaped plastic films require different solutions.

The purpose of marking

The purpose of marking can also vary greatly. For some products, the label can be removed, while other products must not lose their marking without it being destroyed. Inks and stickers must, under certain circumstances, meet special hygienic or food law requirements. In addition, there are numerous requirements regarding the influence that the label may or may not have on its product.

Rising to the challenge with Weber Marking Systems

With over 50 years of experience, Weber Marking Systems is one of the most capable and leading all-round suppliers of labelling solutions. The company is a full-service provider and has made a name for itself as an innovation leader in product marking machines.

What began with labels stuck on by hand is now ready for Industry 4.0: networked, digital processes with short reaction times and decentralised control are a matter of course for Weber Marking Systems solutions. The labelling devices from Weber Marking Systems are always characterised by innovative detailed solutions and overall concepts. In addition to responding to new materials, ever faster production processes and higher demands from customers and legislators, Weber Marking Systems has always placed a high value on easy handling. New employees can quickly learn how to use our labelling machines and can reliably carry out their work with the help of modern interfaces and intuitive user guidance.

Equipped for Industry 4.0

In addition to the pure provision of labelling solutions, Weber Marking Systems goes one crucial step further: at the customer's request, a quality control is also carried out downstream of each labelling step. This not only gives the customer control over the quality of his labelling, but also ensures that each individual product is always recorded. The machines are closely linked to the manufacturing process and react fully automatically to any change or disruption in production. Intelligent asset tracking and management is also made easy with Weber Marking Systems' marking technology.

The professional for your marking applications

As a manufacturing company, the question of labelling your products is always present. Trust the market leader. We at Weber Marking Systems also offer your production an all-in-one solution that significantly complements your manufacturing.

Call us or use our contact form. The initial consultation is free of charge. And if we have gained your trust, you can enjoy the benefits for our existing customers. A 24-hour on-call service is just one of the many benefits that we can offer you as a partner.