QR Code

The QR code, which stands for ‘Quick Response’, is a two-dimensional, square code consisting of a grid of black and white fields. The code can be used to encode a large amount of information in a very small space.

Depending on the amount of information, 2-D codes smaller than 5 x 5 mm can be displayed in a machine-readable format. Thanks to error correction, the QR code can still be read even if up to 25 per cent of the 2D code is destroyed.

Originally developed to optimise logistics processes in the automotive industry, the QR code has established itself as a versatile and efficient tool, particularly in the B2B sector.

Structure and technical advantages of QR codes

The QR code is designed to store large amounts of data in the smallest of spaces, with the information remaining machine-readable. Thanks to its high error tolerance of up to 25% damage, the code remains reliably usable even in harsh environments – a decisive advantage in industrial production, logistics and retail. The various error correction levels (L, M, Q, H) allow adaptation to the specific requirements of industries and applications.

Possible uses of QR codes

1. QR codes for logistics and supply chain management

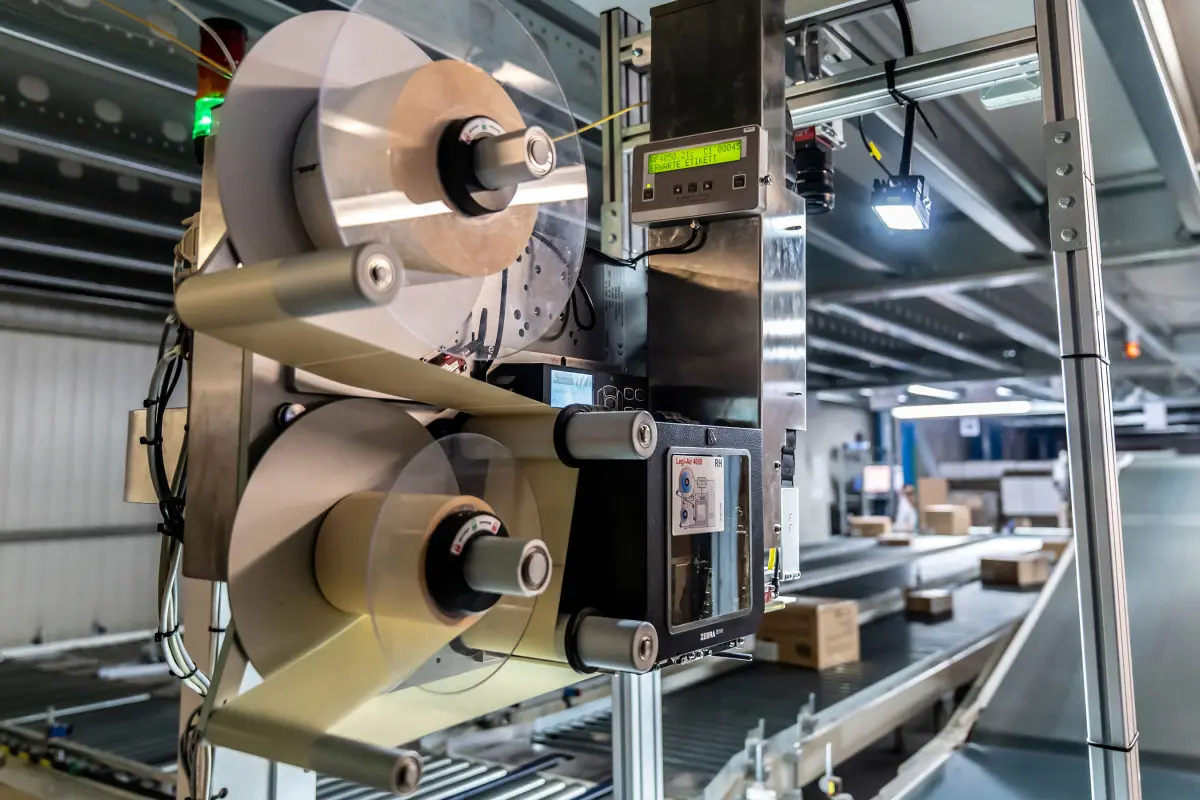

QR codes play a central role in modern logistics. They enable seamless tracking of goods and materials along the supply chain. Areas of application include:

- Incoming and outgoing goods: Automated recording of article numbers, batch numbers and production data.

- Inventory management: Faster inventory by scanning the codes on storage bins or products.

- Delivery tracking: Real-time tracking and delivery updates through integration with ERP and SCM systems.

2. QR CODES FOR PRODUCTION PROCESSES AND QUALITY MANAGEMENT

In manufacturing, QR codes provide an efficient way to provide production data directly to machines or workstations:

- Tool and component labelling: QR codes contain information on specifications, maintenance cycles or serial numbers.

- Process documentation: Automatic linking of production data with specific products for quality assurance.

- Production instructions: Employees can access blueprints or instructions directly by scanning a QR code.

3. QR codes for maintenance and after-sales service

QR codes are an effective tool for maintaining equipment and machinery:

- Maintenance schedules: a single scan provides access to digital manuals, maintenance histories or spare parts lists.

- Fault analysis: QR codes on machines can guide technicians to diagnostic tools or specific support pages.

- Remote support: QR codes enable technicians to quickly access AR applications or virtual manuals

4. QR codes in retail and distribution

In wholesale and B2B distribution, QR codes help to simplify ordering processes and improve customer interaction:

- Digital product catalogue: QR codes on physical brochures or packaging lead directly to extended product information or ordering options.

- Automated reordering: Scanning QR codes on consumables or components to immediately reorder them in the ERP system.

- Product certificates and compliance: Direct access to legally required documents, such as safety data sheets or certificates of origin.

5. QR codes in security and access management

QR codes can also be used for security purposes:

- Access control: Temporary or permanent QR codes for access to specific areas, events or meetings.

- Security tracking: Tracking sensitive materials or products along the supply chain to comply with regulatory requirements.

Benefits of QR codes for companies

- Cost efficiency: QR codes are easy to generate and do not require expensive hardware or infrastructure.

- Time saving: Faster data capture reduces manual work steps.

- Improved data integration: Seamless linking of QR codes with existing systems such as ERP, MES (Manufacturing Execution Systems) or CRM.

- Scalability: QR codes can be adapted for small and large amounts of data, enabling their application in a wide range of industries.

Conclusion

The QR code is a powerful tool that offers a wide range of advantages in the B2B sector. Its robust design, ease of implementation and versatility make it the ideal companion in industry, logistics, manufacturing and beyond. Through integration with modern technologies such as IoT or AR, the QR code will remain an essential part of digitised business processes in the future.