RFID reader

Definition and mode of operation

RFID readers (radio frequency identification readers) are electronic devices that are used for wireless communication with RFID tags or chips. They are used to read or write data from an RFID tag. RFID tags consist of a microchip that stores information and an antenna that enables communication between the tag and the reader. The RFID reader transmits a radio signal that is received by the tag's antenna. As soon as the tag recognises the signal, it sends the stored information back to the reader, which then processes it further.

Technological basics

RFID readers work on the basis of electromagnetic waves, whereby a distinction is made between different frequency ranges depending on the technology. There are three main types of RFID systems:

- Low frequency (LF) - typically at 125 kHz or 134 kHz: Often used in access control systems or for animal identification.

- High frequency (HF) - at 13.56 MHz: Often used in payment and ticketing solutions or for contactless smart cards.

- Ultra High Frequency (UHF) - at 860 to 960 MHz: Used in logistics and supply chain management as it offers a greater range and higher transmission speed.

The RFID reader receives the data transmitted by the tag's antenna and can decode it. With activated tags, communication takes place using the energy emitted by the reader, while passive tags have no energy source of their own and the energy from the reader is used to activate the tag.

Components of an RFID reader

- Antenna: Transmits the radio signal and receives the signal sent back by the RFID tag. The size and type of antenna affect the range and performance of the system.

- Signal processor: Analyses the received data and converts it into a format that the system can understand.

- Communication interface: Transmits the read-out information to a connected system such as a computer, network or database. This can be done via serial, USB or wireless connections.

Types of RFID readers

- Handheld readers: Portable devices that are used manually to scan RFID tags. They are particularly useful in mobile applications and inventory management.

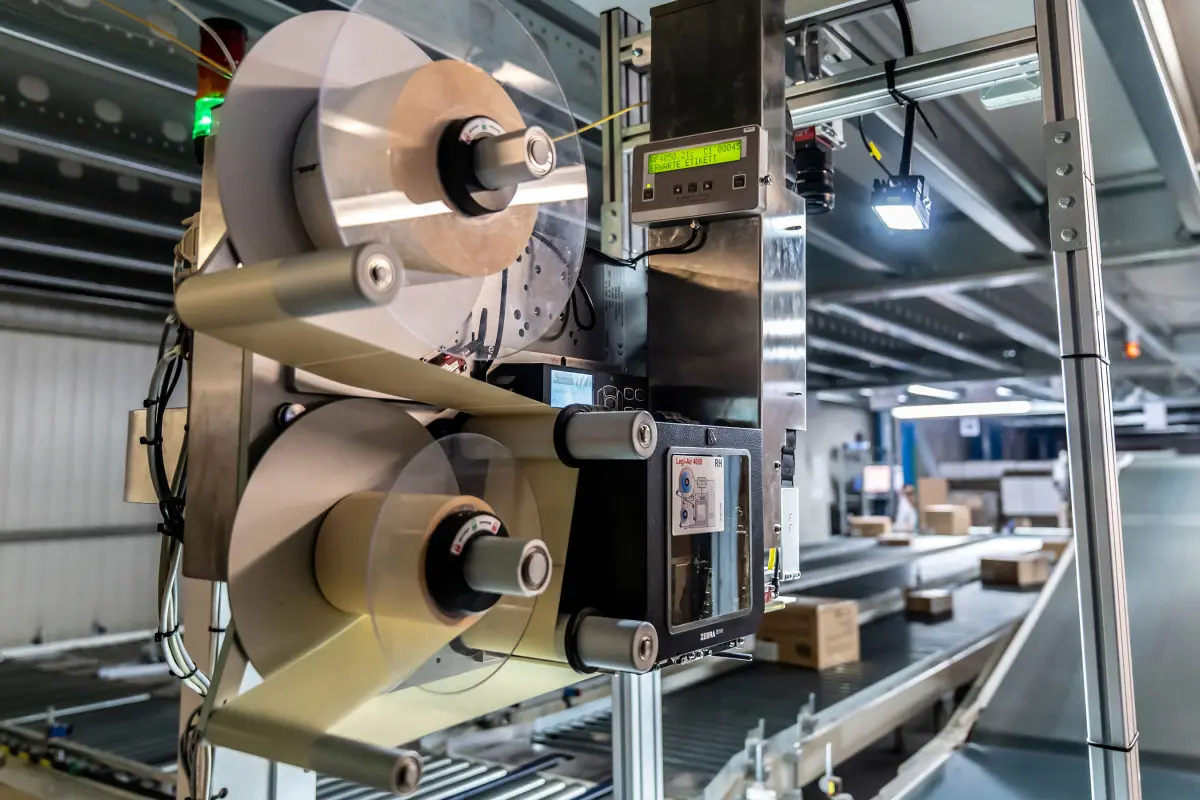

- Stationary readers: Often used in fixed systems, such as gate entrances, to automatically recognise RFID tags without the need for manual interaction.

- Integrated readers: These are built directly into machines or devices and enable the automatic identification of objects without the need for separate readers.

Areas of application

RFID readers are used in various areas, including

- Logistics and supply chain: for tracking goods and stock, managing pallets and containers.

- Access control: In security systems, to identify people or vehicles.

- Animal identification: In agriculture, for monitoring animals using RFID tags on collars or ear tags.

- Smart cards and payment systems: In contactless payment systems or for access to public transport.

Advantages of RFID readers

- Contactless identification: The RFID reader does not require direct contact with the RFID tag, which makes it easier to handle and use.

- Speed and efficiency: Multiple RFID tags can be read simultaneously and without delay, which saves time in logistics and warehousing systems.

- Reliability: RFID readers are less susceptible to interference from dirt, scratches or other physical damage that can occur with conventional barcodes.

- Automation and real-time tracking: The use of RFID technology enables almost complete automation of processes and precise tracking of objects in real time.

Challenges and future prospects

Despite their many benefits, there are also challenges that affect the use of RFID readers, such as the cost of infrastructure, the need for integration into existing systems and privacy concerns regarding the potential traceability of people or objects. In the future, however, the development of more efficient and cost-effective technologies and the increasing use of IoT and big data will help to further spread and optimise the use of RFID.

In summary, RFID readers are central components of modern identification systems that are widely used in various industries thanks to their versatility and efficiency and are increasingly contributing to the automation and digitalisation of processes.