Tamper Evident

Transparent seal label as tamper protection on a folding box

You have currently selected the following location:

Now switch to the following location:

Tamper protection is an important issue for many manufacturers – often in connection with protection against counterfeiting. Did you know that you can protect your products from unauthorised opening with the right marking system?

This not only makes it more difficult for product pirates to get into your products, but also increases buyers' trust in your brand. Read on to find out how Weber Marking Systems can help you with this task.

Transparent seal label as tamper protection on a folding box

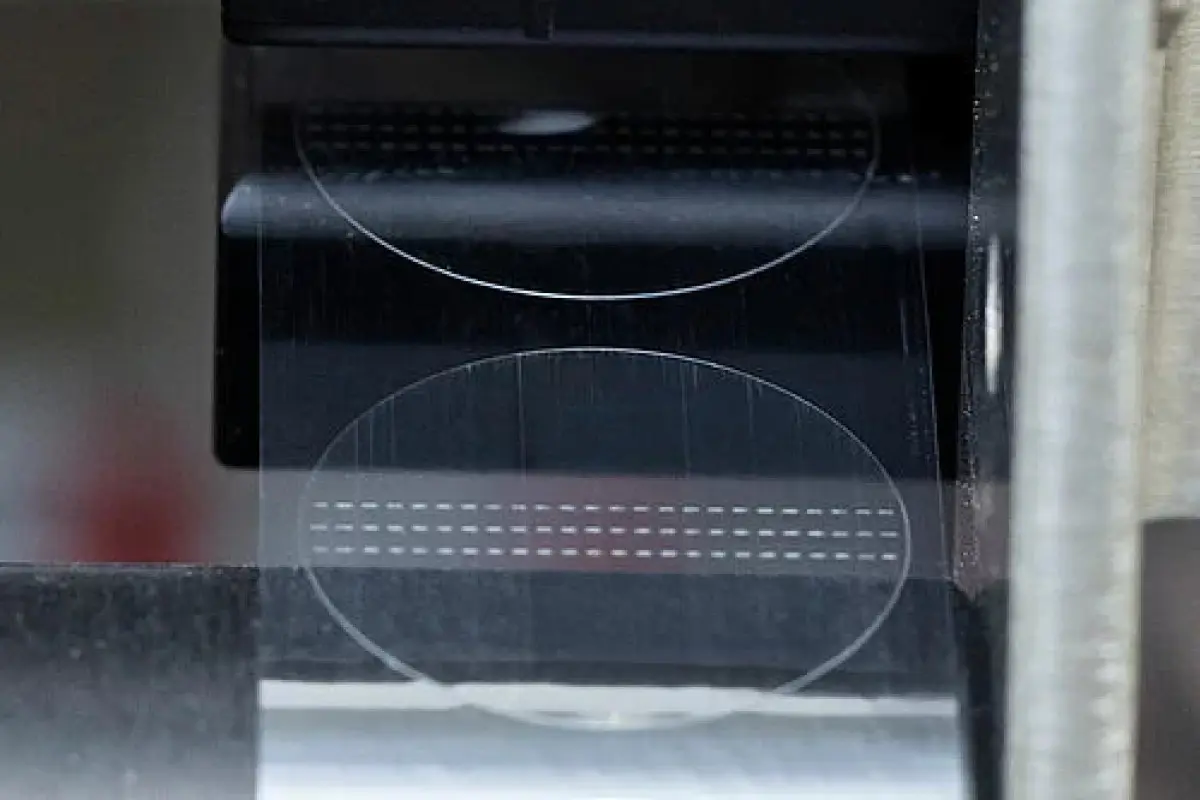

Perforated sealing label during application

Whether it's medication, food or cosmetics, seal stickers assure consumers that the product is still in its original packaging. In the pharmaceutical industry, such proof is even mandatory in addition to serialisation from 2019: under the Falsified Medicines Directive 2011/62/EU, every prescription medicine must have first-opening protection as a further security feature.

To provide effective tamper protection, the seal labels must leave a visible ‘trace’ when they are first opened. This usually occurs when the packaging is irreversibly damaged when the label is removed. There are various options for this form of product protection:

Besides sealing, there are other methods such as cellophane-wrapping, gluing or special folding techniques. However, closure labels have clear advantages: the corresponding labelling machines can usually be integrated into existing production with little effort. This means that there are no costs for new packaging, new equipment or the conversion of the packaging line.

Furthermore, transparent labels have less of an impact on the packaging design, so that, for example, overlaid text remains legible. By contrast, white blank labels provide space for additional information such as serialisation data.