Weihenstephan Standards (WS)

Communication interface for machines

Today's food and beverage manufacturers are under particular pressure to offer high-quality products at competitive prices. In doing so, they are caught between the conflicting priorities of their own profitability and a high level of responsibility towards consumers and legislators. In order to remain competitive, they are dependent on effective information technology support from various production management systems, such as Manufacturing Execution Systems (MES). To this end, the exchange of data between machines (M2M) and higher-level IT systems is becoming increasingly important. However, the complexity increases, especially in heterogeneous production lines with different machine suppliers or IT providers.

The Weihenstephan Standards (WS) define a communication interface for the standardised transfer of machine and process data to higher-level IT systems. The metamodel is based on the industry standards OPC UA and PackML. The WS can be implemented quickly and easily in all machines in the food and beverage industry.

WS domains

The Weihenstephan standards define both universally applicable communication interfaces and the data that must be provided for data acquisition. The required data points and content as well as the evaluation recommendations have been defined on an industry-specific basis and are currently available for the following industries:

- Beverage bottling plants

- Machines in the food industry

- Machines in the bakery industry

- Process plants in the brewing industry

- Machines in the confectionery industry

Advantages of the Weihenstephan standards

The Weihenstephan standards offer predefined and standardised data content as well as uniform communication interfaces and WS software tools that significantly reduce the effort involved in project planning and implementation. The use of Weihenstephan standards therefore saves time and costs during IT integration.

- Definition of practice-relevant data points

- Definition of extensive machine profiles

- Use of the OPC UA communication standard

- Availability of modelling tools

- Possibility to check the successful implementation

- Industry-specific evaluation recommendations

- Manufacturer and controller-independent implementation

- Interdisciplinary and pre-competitive collaboration between machine builders, production companies, IT integrators and researchers

- Common goal of driving forward a standard within the food and beverage industry

- Independent perspective from science and research by TUM

Definition of the communication interface

In the Weihenstephan standards, the two communication standards WS OCP UA and WS Protocol are available for the transmission of WS data points. They define the form in which the data is structured and transmitted. WS OCP UA has been available since version 10 of the Weihenstephan standards. Among other things, this offers advantages in the self-description of data. WS Protocol, a proprietary TCP/IP protocol, is also available.

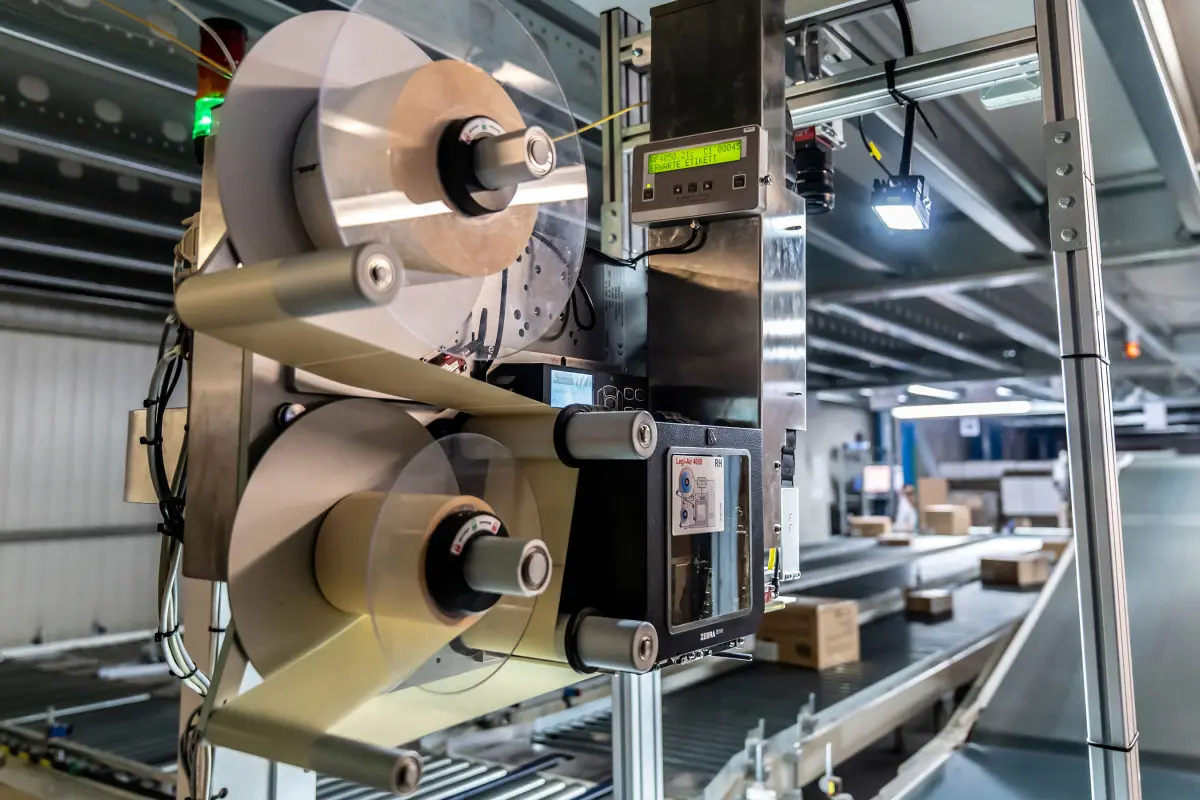

Digitisation with labelling solutions

Weber Marking Systems offers various software programs for most labelling machines. Bluhmware, Loftware Nice Label, Legitronic, Linx Printernet or integra Command support the processes of digitisation and industrial automation. You are welcome to arrange a consultation with our experts!