How does RFID labeling work?

RFID (Radio-Frequency Identification) is a wireless identification technology that transmits data via radio waves. The technology is used in transmitter-receiver systems that can identify and localise objects automatically and without physical contact. RFID systems are used in very different areas - for example in Industry 4.0.

Each RFID system consists of an electronic data carrier (RFID transponder) and a reader (RFID reader). Both components have an antenna that can be used to exchange data. Radio waves, which are magnetic or electromagnetic waves, serve as the transport system.

RFID technology enables the automatic identification of products and transport containers in industrial production and logistics as well as in retail. With our systems, you can create, print and automatically apply RFID labels. The labels contain an RFID transponder - a microchip with an antenna on which data can be stored, changed and deleted. An RFID reader can read and encode them.

Our RFID solutions:

RFID Readers

RFID readers enable fast and reliable recording of stored data - contactless and in real time.

Whether for warehouse management, inventory control or process automation - mobile RFID readers ensure efficiency, transparency and security. They optimise work processes, reduce sources of error and enable seamless tracking of goods and products.

RFID printers

RFID printers combine the classic printing process with the simultaneous encoding of RFID tags.

They are specially designed for creating individually printed and programmed RFID labels. In contrast to RFID readers and labelers, the focus here is on precise data encoding and individual printing - a decisive advantage for logistics, production and retail.

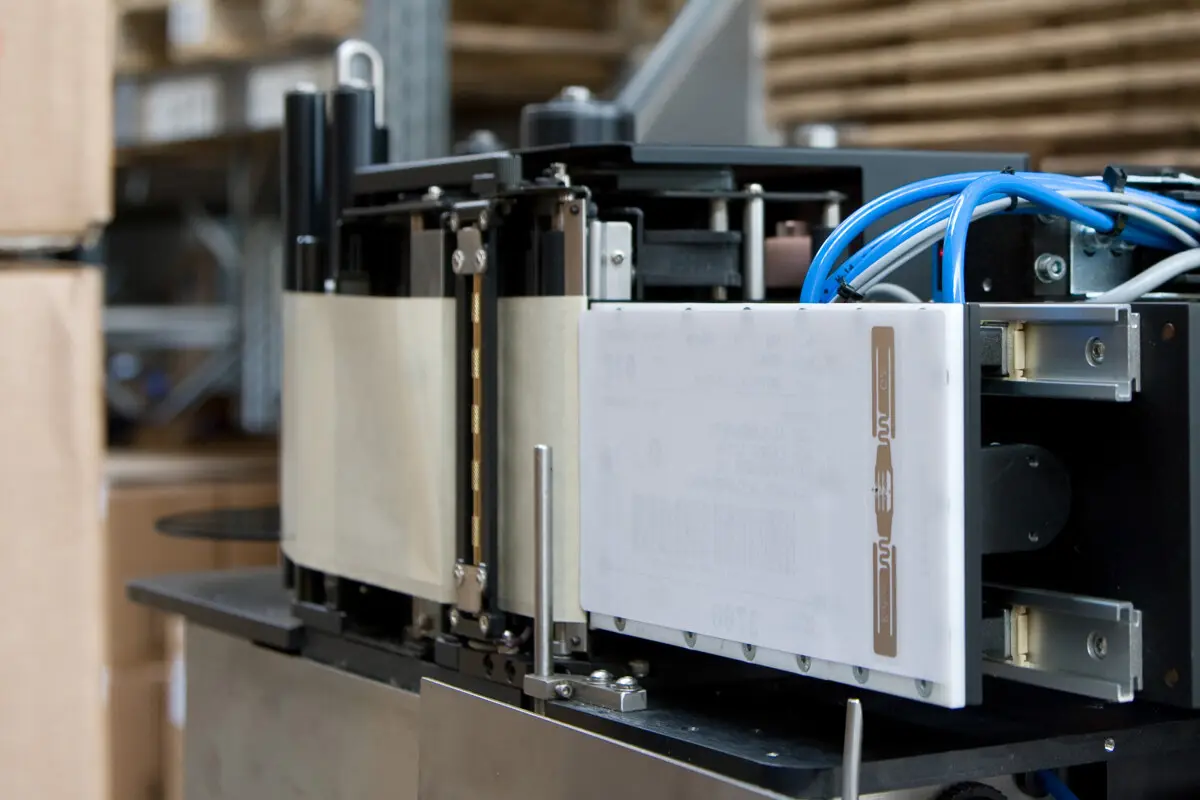

RFID labeling machine

RFID labeling machines automate labeling processes.

They combine printing and application functions for efficient, error-free labeling of products, packaging and pallets.

Frequent areas of application for RFID technology

RFID has a wide range of possible applications. Basically, the technology is suitable for the automatic labeling, recognition, registration, storage and monitoring of individual parts or transport containers. Here are a few examples:

Production control

In industrial production, the information on the RFID chip can document the current construction status of a product. Further process parameters are specified on this basis. This approach is already widely used in the automotive industry in particular.

Track and trace

All data relevant to production and origin can be stored in an RFID tag so that goods can be clearly traced back along the supply chain to the place and time of production. In some cases, complete traceability is required by law.

Inventory management

Among other things, libraries use radio tags to control the correct borrowing and return of media at self-checkout terminals.

Asset management

RFID labels make it possible to monitor and document the storage, delivery and production routes of material assets in real time and to incorporate them into process planning (asset tracking).

Warehouse management

Using RFID, pallets can be automatically recorded at goods receipt, booked in the inventory management system and transported to the designated shelf location.

Product protection

RFID transponders are used in high-quality branded products to distinguish originals from counterfeits during authenticity checks.

Access control and time recording

In many companies, RFID chips are used for automatic access control in entrance areas and/or to record employees' working hours at designated terminals.

Advantages of RFID technology

- Contactless procedure: The data is transmitted via radio antennas from the transponder to the reading device or from the writing device to the transponder. Neither visual contact nor physical contact is required. The radio signals can penetrate various materials. This not only ensures faster detection of goods, but also makes it easier to reach inaccessible parts.

- Fast data exchange: The radio transmission of data between transmitter and receiver takes place with almost no time delay.

- Bulk reading: RFID readers can read several RFID tags in large quantities at the same time. Theoretically, it is therefore possible to capture all the products on a pallet or transport container in just one scan.

- Virtually error-free: RFID labels have a first read rate of up to 100%. Additional security is provided by RFID systems that can recognise and reject faulty tags.

- Security through encryption: Instead of plain text, data can be transmitted in encrypted form to enable access control.

- Resistant: RFID tags are not affected by extreme environmental conditions such as high temperature fluctuations, heat, cold or humidity. Even products that later undergo special post-treatment or cleaning processes can be reliably labeled using RFID.

- Reusable: In contrast to printed barcodes, the data on an RFID chip can be changed and added to at a later date.

- Invisible: The tiny RFID transponders can be integrated inconspicuously into most labels.

Alternatives to RFID

Have you ever considered alternative technologies? At Weber Marking Systems, you can find them all from a single source!

Your personal contact from our sales team will discuss possible alternative technologies with you and find the most economical and productive solution for your labeling task. If the task is particularly complex, the various technologies can of course also be combined with each other. The compact and modular design of our labeling devices makes this possible.

Inkjet printing

Inkjet technology is a suitable alternative to RFID technology. Relevant data can be printed on almost any surface. Special UV or security inks are used for counterfeit protection and inconspicuous traceability along the supply chain because these inks are only visible under UV or black light.

Laser marking

Laser marking is permanent and particularly worth considering if the coding needs to be resistant to heat, chemicals and mechanical stress.

Frequently asked questions about RFID

Do I need RFID labeling software?

The NiceLabel labeling software connects your RFID printer to any database (Excel, ERP system, etc.) and supports you in coding and designing your RFID labels. We are happy to provide you with a trial version free of charge for 30 days.

Your reliable partner

Weber Marking Systems is a leading full-service provider of industrial marking technologies. With a focus on innovation, quality and sustainability, we develop cutting-edge labeling and coding systems that meet the requirements of our customers in every industry sector. Our international sales network guarantees excellent world-wide support and service. No matter what challenges your application presents: We have the necessary experience to work with you to find the optimum solution.

- Your personal consultant will listen to you and explain the possibilities.

- We will develop the perfect solution for your application.

- Our international service network is always there to support you.

- You can rely on high-quality products made in Germany.

- Get all systems, consumables and services directly from a single source.