How does inkjet printing work?

Inkjet printers create a printed image on a surface by shooting or deflecting small droplets of ink through air from a print head.

In contrast to conventional office printers, industrial inkjet printers have separate print heads that can be installed variably and directly in the production lines. They also print much faster and are designed for high-speed industrial lines. They are also designed to be much more robust so that they can withstand harsh conditions and deliver the best results even in dusty, hot and humid environments.

In the industrial environment, marking is carried out using inkjet either in the so-called continuous inkjet or drop-on-demand process. The drop-on-demand process can in turn be divided into thermal and piezo inkjet printing. Inkjet technology is also sometimes used in prin and apply systems.

Our inkjet printers

Drop-on-Demand (DOD)

The two most important drop-on-demand printing technologies are thermal and piezo inkjet printing.

In both processes, positive and negative pressure waves ensure that ink drops are ejected from the nozzles of the print head on demand. Markings applied using the DOD process are characterised by a very high print resolution. In addition, particularly large print images are possible with this technology. DOD printing is therefore very suitable for printing large characters.

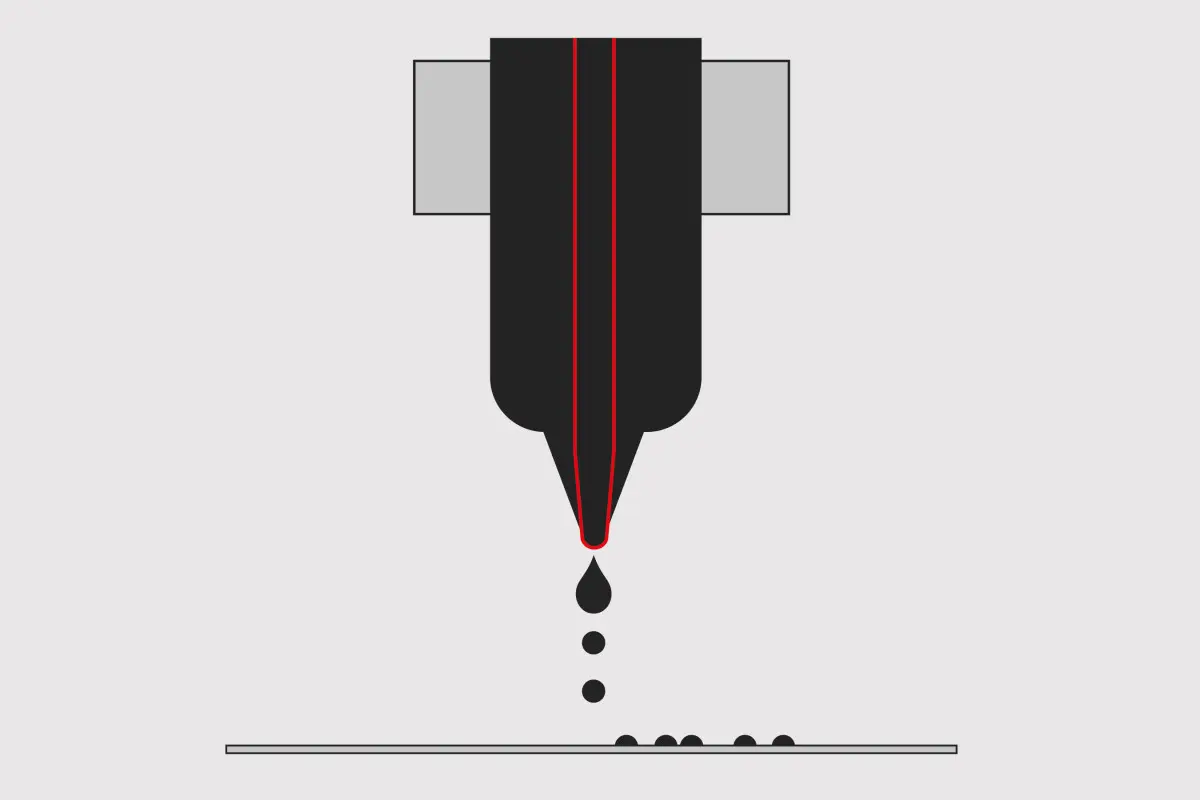

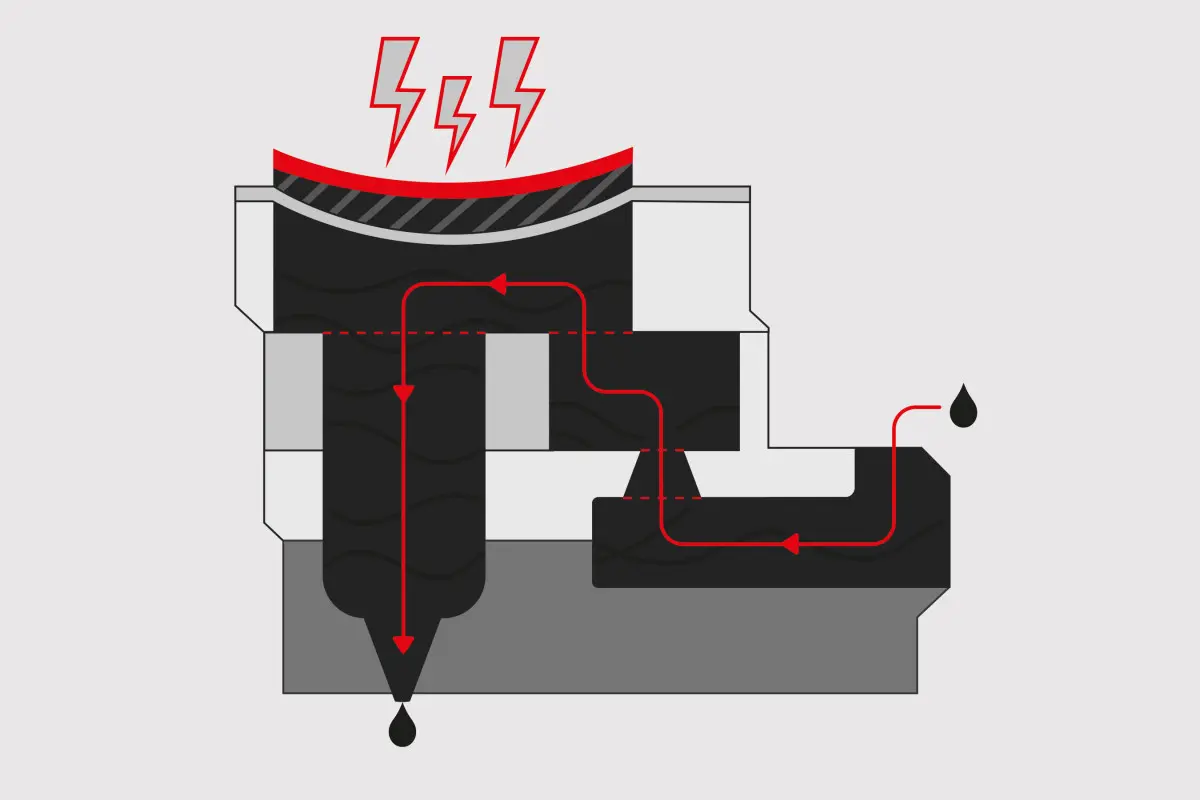

Piezo Inkjet (PIJ)

Piezo printers impress with the long service life of the print heads, razor-sharp print results and extremely fast printing speed.

Piezo printers utilise the so-called piezoelectric effect: When piezoelectric material (piezoelectric crystals or ceramics) is elastically deformed, an electrical voltage is generated on its surface. Conversely, the material deforms when electrical voltage is applied. The piezo element briefly deforms the pressure nozzle. This creates high pressure on the ink, causing a drop of ink to be ejected from the print head. To prevent the ink from escaping from the nozzle unhindered, the polarity of the piezo element is reversed so that it deforms in the other direction. This pulls the ink back with it.

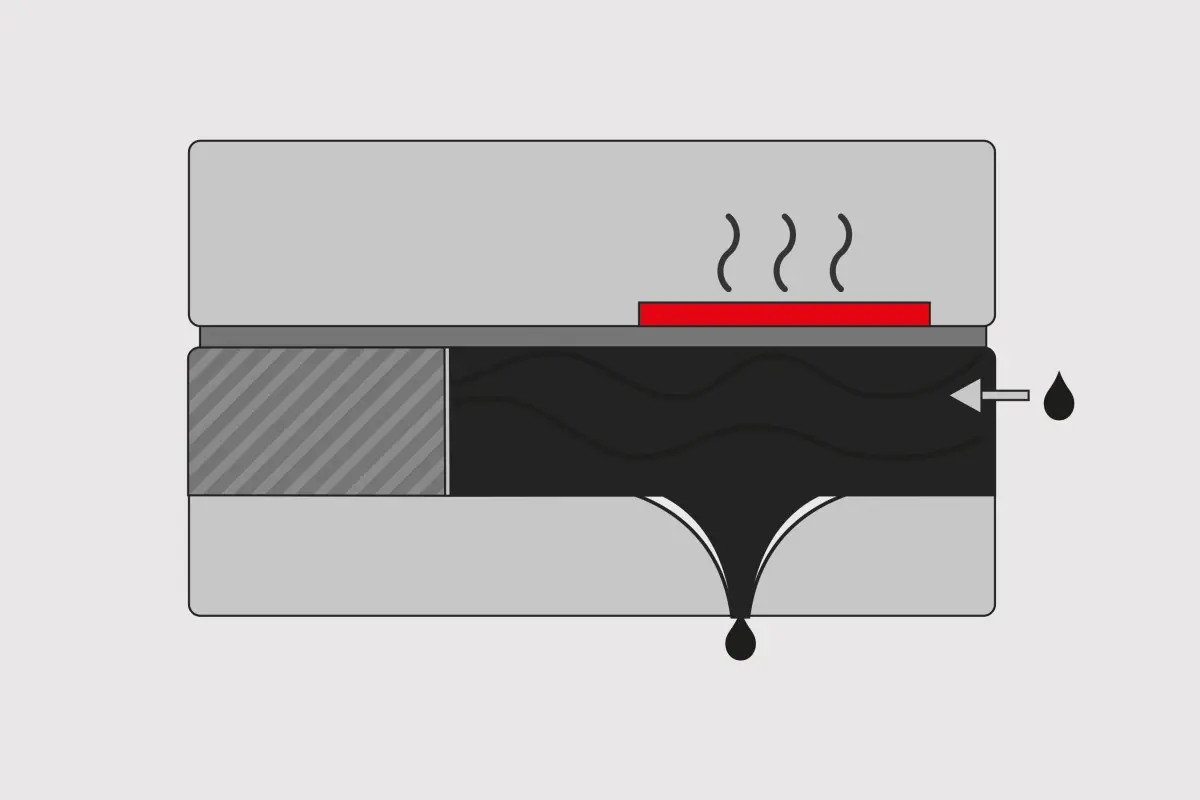

Thermal Inkjet (TIJ)

Thermal inkjet printers (also known as thermal inkjet coders) print particularly cheaply, yet quickly and precisely.

Ink is normally viscous and has a certain surface tension. This is why it does not leak out of the cartridge prematurely. The ink cartridges of thermal inkjet printers have a series of tiny electrically heated chambers in which a vapour bubble is generated by pulses. This pushes the ink droplet through the nozzle and places the droplet precisely on the material to be printed. The contraction of the vapour bubble ensures that ink is drawn from the ink reservoir into the chambers and shot out again within a hundred millionth of a second.

Common areas of application for inkjet printers

Industrial inkjet printing is a widely used technology in modern marking technology. It enables precise, flexible and economical labeling of a wide variety of materials. Manufacturers from a wide range of industries use this technology for labeling products and their packaging. Here is a small selection of common areas of application:

Beverages and food

Best-before date on bottles, cans and food packaging, batch numbers for traceability.

Automotive and electronics industry

Serial numbers and production data on parts, components and cables for unique identification.

Pharmaceuticals and cosmetics

Article numbers on blister packs, tubes and cans, serialisation data and 2D codes on folding cartons.

Advantages of inkjet printers

- Non-contact labeling: As only the ink droplets come into contact with the surface, even uneven, moving and sensitive products or packaging can be reliably labeled.

- Changing print content without changeover: In contrast to offset or gravure printing, inkjet printers do not have a fixed printing form. This means that variable content (text, codes, sequential numbers, graphics) can be printed directly one after the other on the conveyor belt. Information such as time, date or batch number is simply transferred from a database.

- High printing speed: Inkjet printers impress with their high printing speeds and are designed for labeling on high-speed lines.

- Many possible applications: Thanks to a wide range of different inks and special accessories, our inkjet printers are suitable for almost all industries, materials and applications.

- Low printing costs: Inkjet printing can be a cost-effective alternative to labeling - for example, for carton labeling for internal logistics.

- Continuous printing: Inkjet printers allow products to be printed in a continuous flow. A stop for labeling can be implemented, but is not absolutely necessary, which significantly speeds up production.

Alternatives to inkjet printing

Have you ever considered alternative technologies? At Weber Marking Systems, you can find them all from a single source!

Your personal contact from our sales team will discuss possible alternative technologies with you and find the most economical and productive solution for your labeling task. If the task is particularly complex, the various technologies can of course also be combined with each other. The compact and modular design of our labeling devices makes this possible.

Labeling

With labeling technology, you can achieve equally high-quality and reliable product and packaging markings. Depending on the system, these also label without contact, either in stop or continuous mode. Labeling can be carried out from above, below, sideways, over the corner, all-round, single-sided and multi-sided.

Laser labeling

Depending on the production environment and speed, our laser systems are an alternative technology to inkjet printing. Although laser markers are somewhat more expensive to purchase, they save costs during operation as they do not require consumables such as ink or labels, nor do they have maintenance parts. Laser labeling is permanent and is particularly worth considering if the coding needs to be resistant to heat, chemicals and mechanical stress.

Marking different surfaces

Thanks to the particularly large variety of inks, almost all materials can be labeled perfectly with inkjet printers. Discover some practical application examples here.

Frequently asked questions about inkjet technology

How do I choose the right inkjet printer?

Depending on the application, different inkjet systems may be used. The following criteria, among others, should be considered when selecting:

- Material of the surface to be labeled: Surfaces can be categorised into absorbent or porous substrates (e.g. cardboard, wood, paper) and non-absorbent or smooth substrates (plastic, metal, glass). The printer must be able to use an ink that achieves satisfactory results in terms of print image, intended use and drying time.

- Size of inkjet coding: Depending on the print content and the space available, inkjet printers can achieve different character heights and numbers of print lines in a single operation.

- Production speed: Depending on how many products or packages (stationary or moving) need to be labeled per minute, standard or high-speed systems are available.

- Print volume and uptime: Systems with large ink supplies prevent frequent cartridge changes from unduly affecting the overall efficiency of the system. For non-stop production, there are printers that can be refilled during operation without downtime.

- Mobility and available space: Is the printer in a fixed location or does it need to be easy to transport? If space is limited, a particularly compact system or a long print head supply line should also be chosen.

- Installation position of the print head: In principle, labeling from above, below or from the side is possible. However, not every printing system can fulfil all positions equally well due to the design.

- Environmental conditions: In industry, harsh environments often prevail in which the inkjet printer is exposed to dust, moisture, vibrations or strong temperature fluctuations. In addition to a robust design, a certain IP protection class or special protective devices may therefore be required.

- Downtime: During longer breaks, there is a risk that the ink will dry or the print nozzle will become blocked. This can be prevented by inkjet printers with automatic nozzle sealing or automatic print head rinsing before stopping. They are ready to print again in no time after long periods of inactivity.

What is the difference between laser printers and inkjet printers?

Laser printers, as we know them from our homes or offices, cannot be compared with industrial inkjet printers. They are suitable for occasional printing on paper and film. They work on the basis of the so-called electrophotographic process, in which an electrically charged drum is selectively discharged by light beams. However, laser printers are sometimes also used to refer to industrial marking lasers, which use focused light to create a printed image – without the need for ink. These, in turn, can actually be an alternative to inkjet printing under certain circumstances.

Your reliable partner

Weber Marking Systems is a leading full-service provider of industrial marking technologies. With a focus on innovation, quality and sustainability, we develop cutting-edge labeling and coding systems that meet the requirements of our customers in every industry sector. Our international sales network guarantees excellent world-wide support and service. No matter what challenges your application presents: We have the necessary experience to work with you to find the optimum solution.

- Your personal consultant will listen to you and explain the possibilities.

- We will develop the perfect solution for your application.

- Our international service network is always there to support you.

- You can rely on high-quality products made in Germany.

- Get all systems, consumables and services directly from a single source.