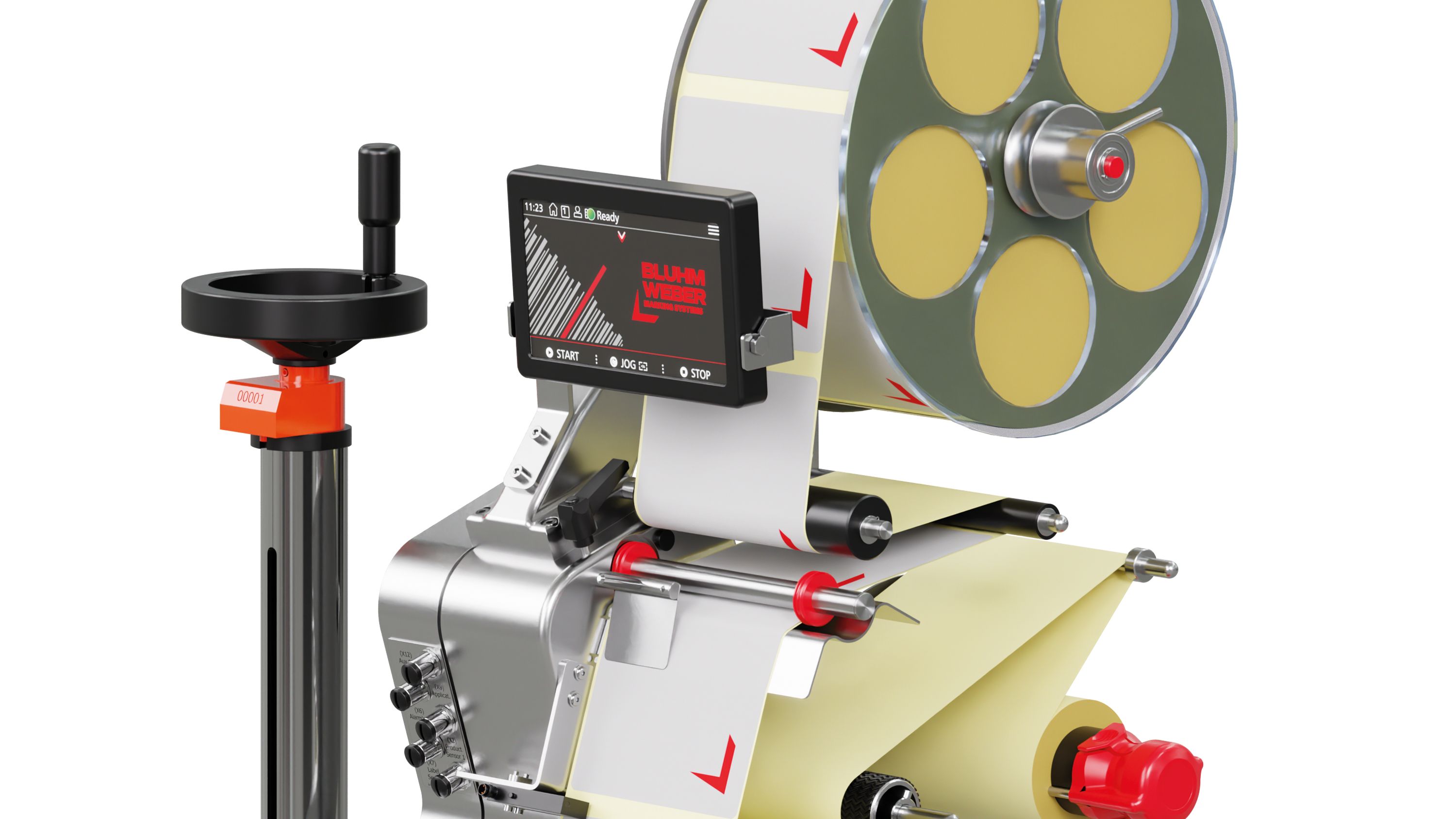

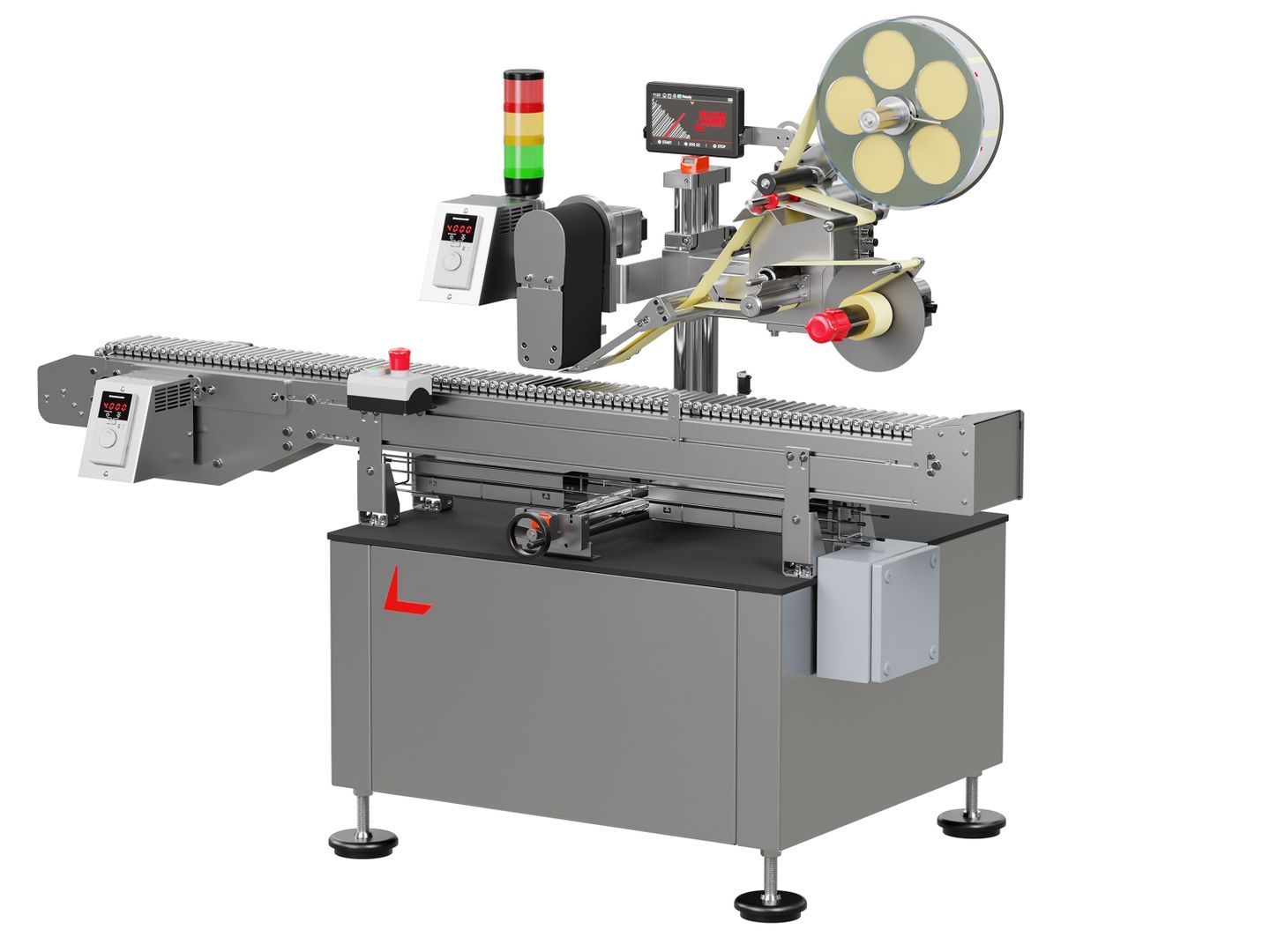

Developed for easy operation and system integration

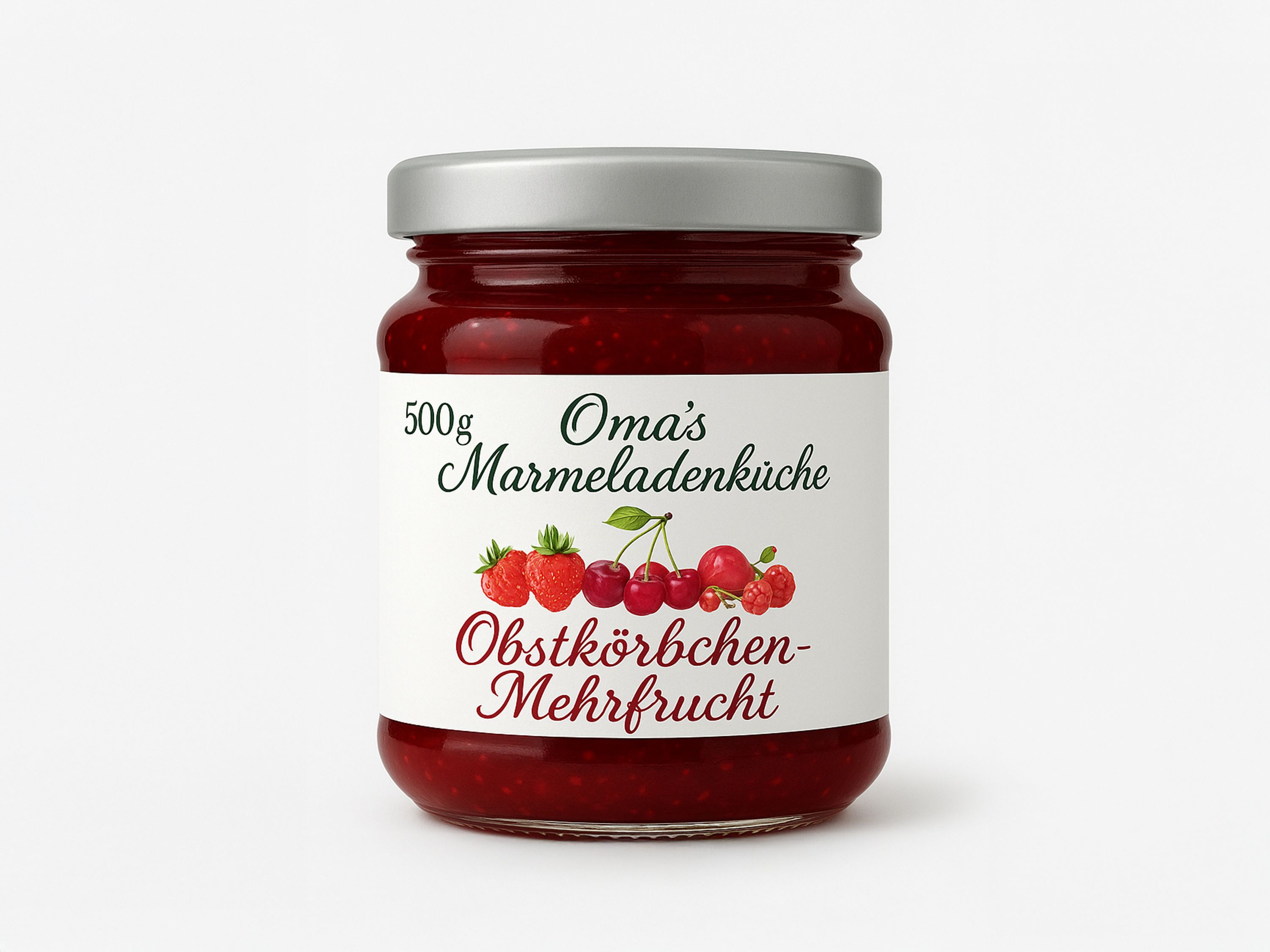

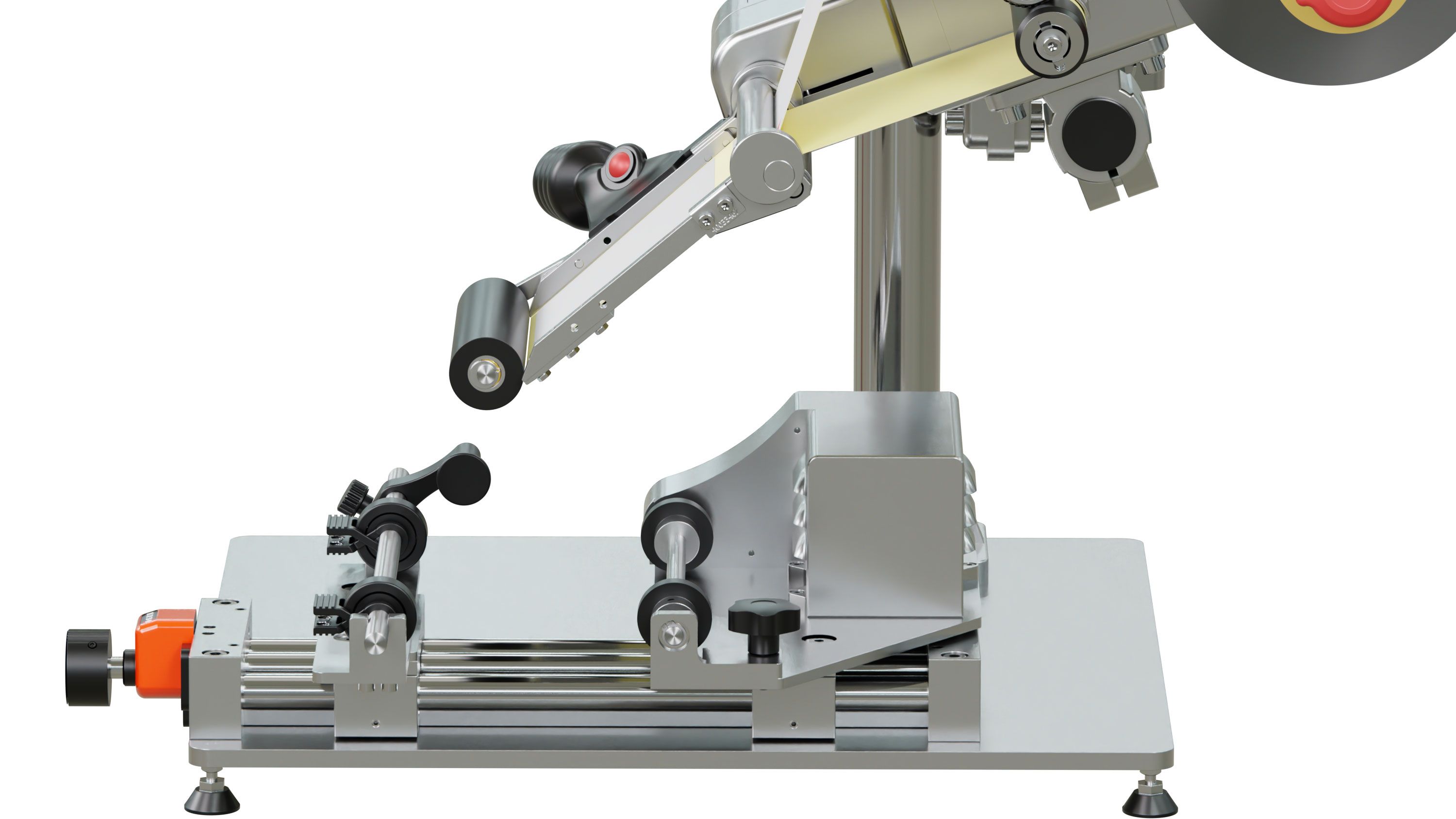

The Geset 141 semi-automatic labeling system has been specially developed for maximum user-friendliness. The system labels cylindrical products all around the lateral surface and can be adjusted to different product sizes. The product is manually inserted into the roller system by the user and operated using a lever and foot switch. Labeling is carried out by an Alpha Compact label applicator. Operation is particularly simple and intuitive - ideal even for less trained personnel. Short set-up times for batch changes increase output.