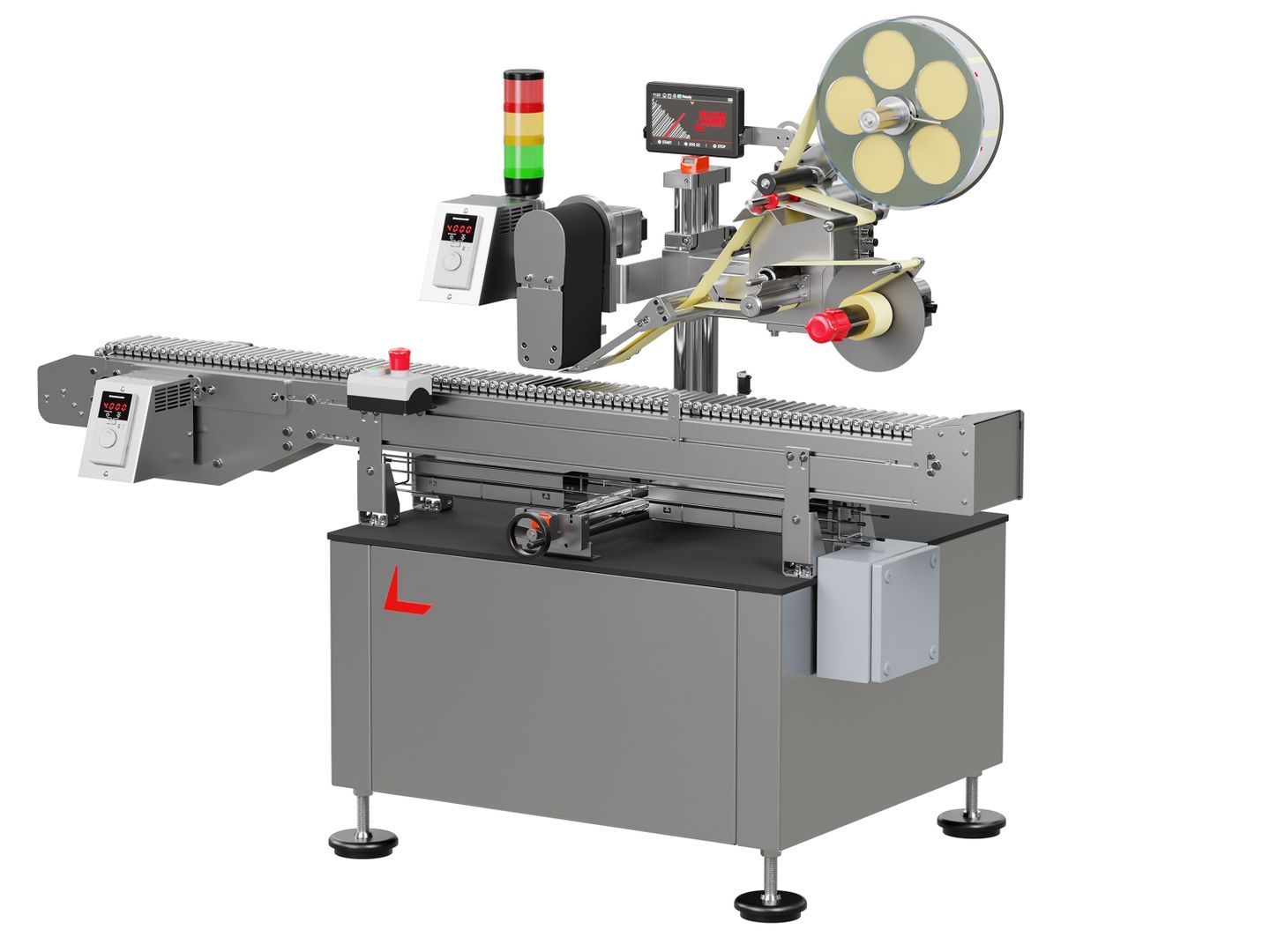

Developed for easy operation and system integration

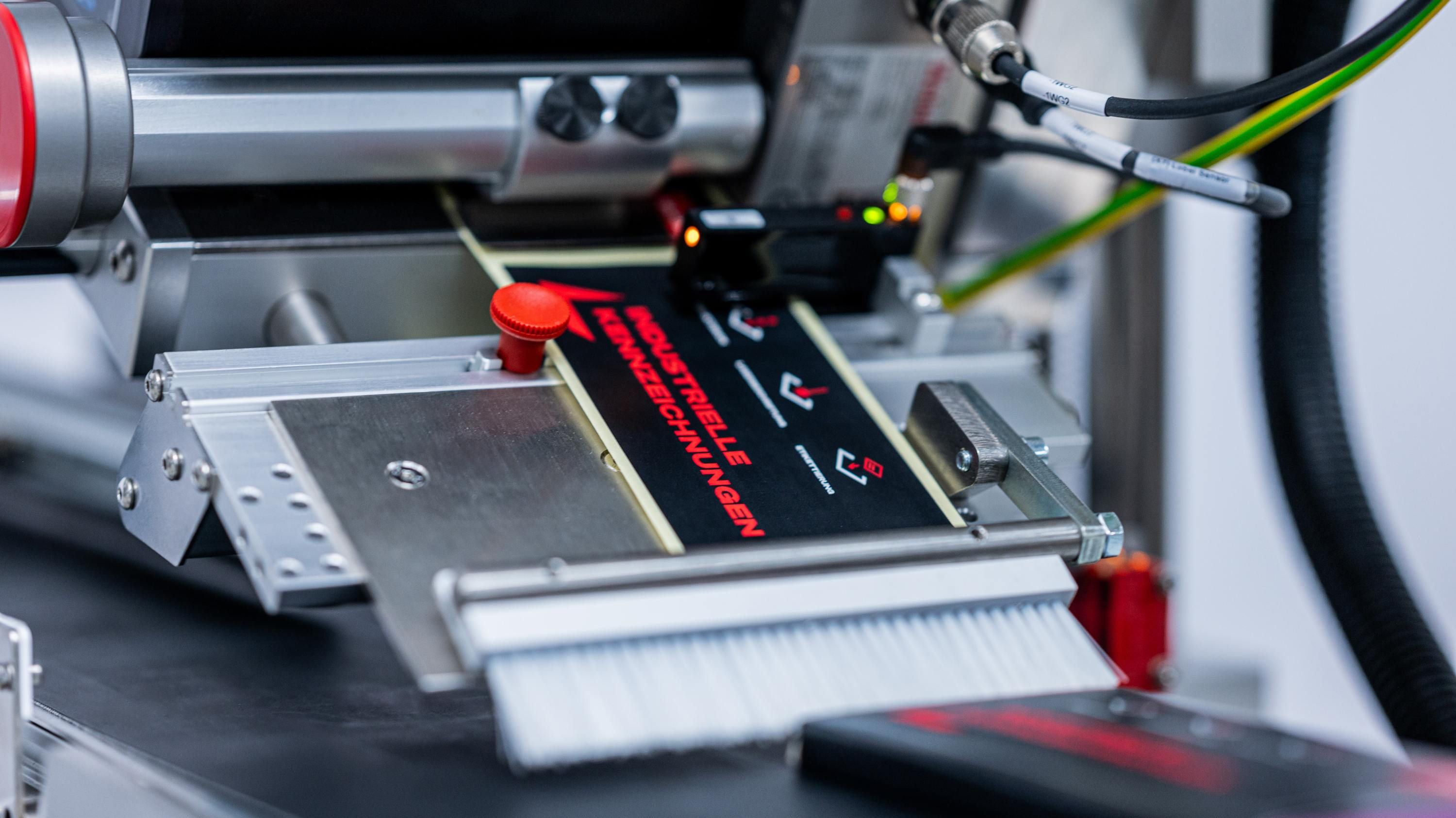

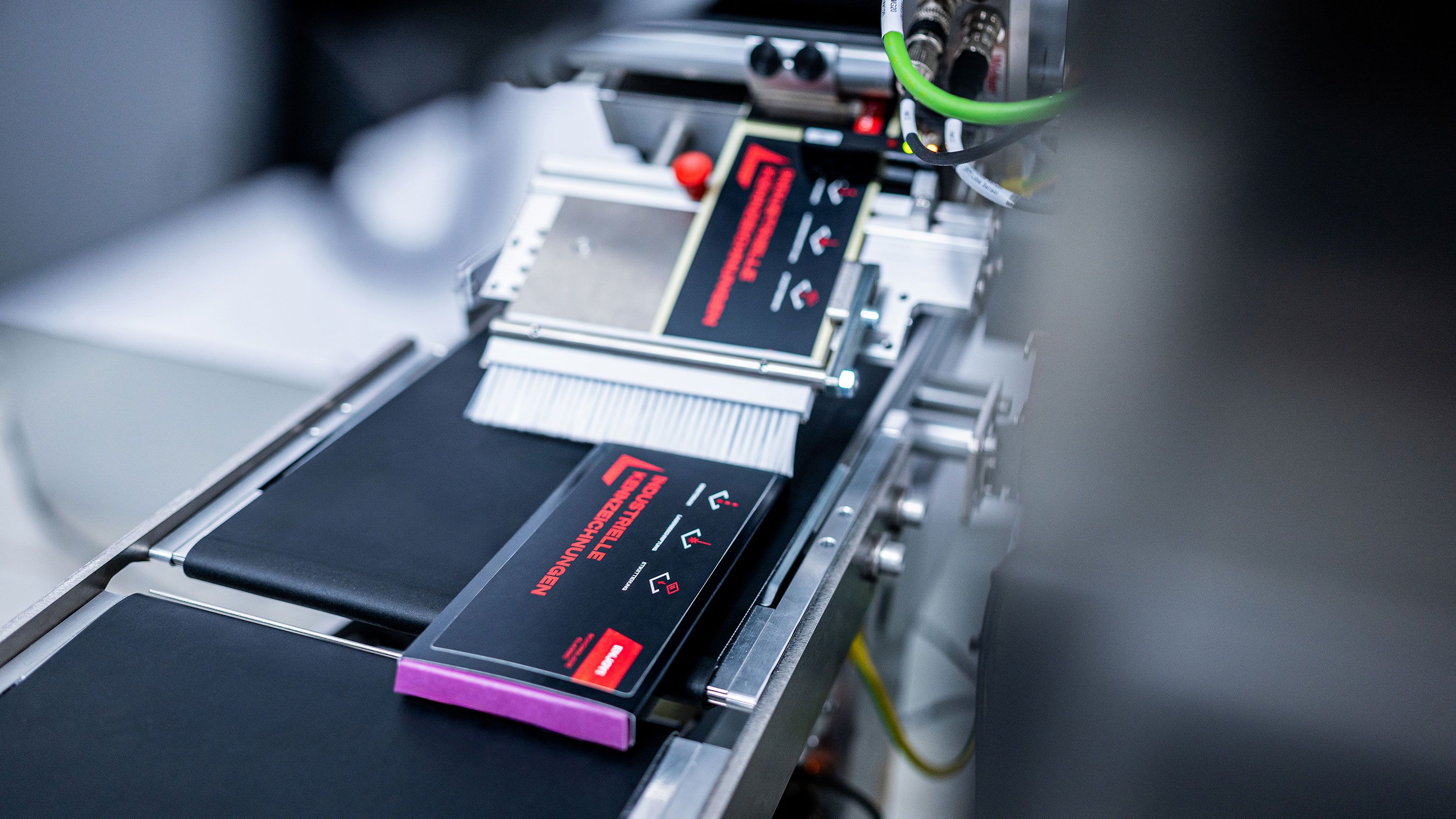

The CE-compliant Geset 217 labeling system has been specially developed for maximum user-friendliness and easy integration into existing production lines. The modular system labels products reliably on the top and bottom. The integrated conveying system ensures a consistently stable product flow in the labeling process. Labeling is carried out by two Alpha HSM high-speed label applicators. Thanks to the central touch display and near-field operation, controlling is intuitive - ideal even for less trained personnel. Fast roll and format changes reduce downtimes and increase flexibility. Product and label-dependent parameters can be saved and called up directly. The compact construction with integrated controller housing, plug-in components and clear design saves space and simplifies maintenance. The system can also be fully remotely maintained for fast and efficient support. With various interfaces, it can be seamlessly integrated into modern production environments.