The uncomplicated introduction to large character printing

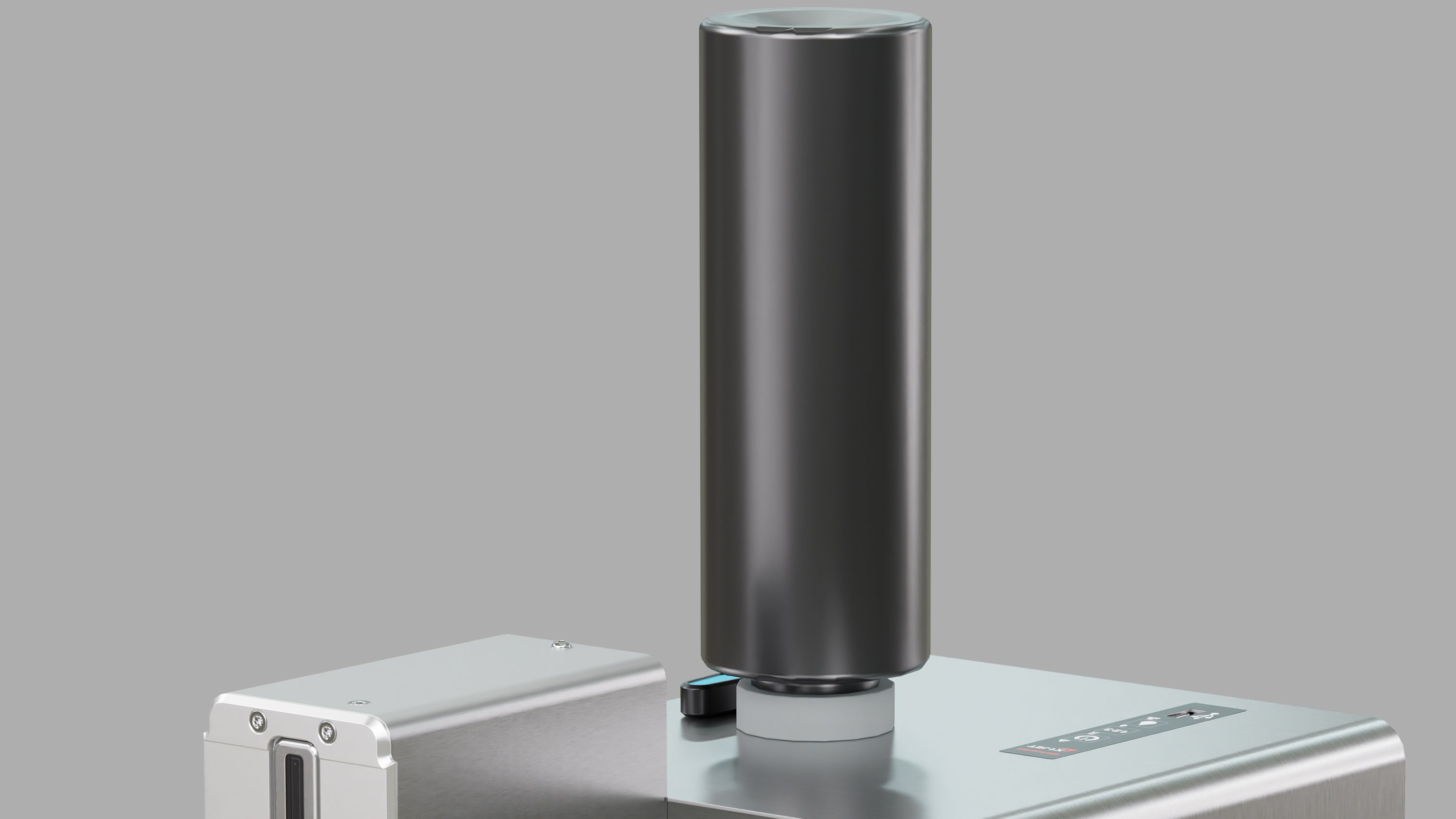

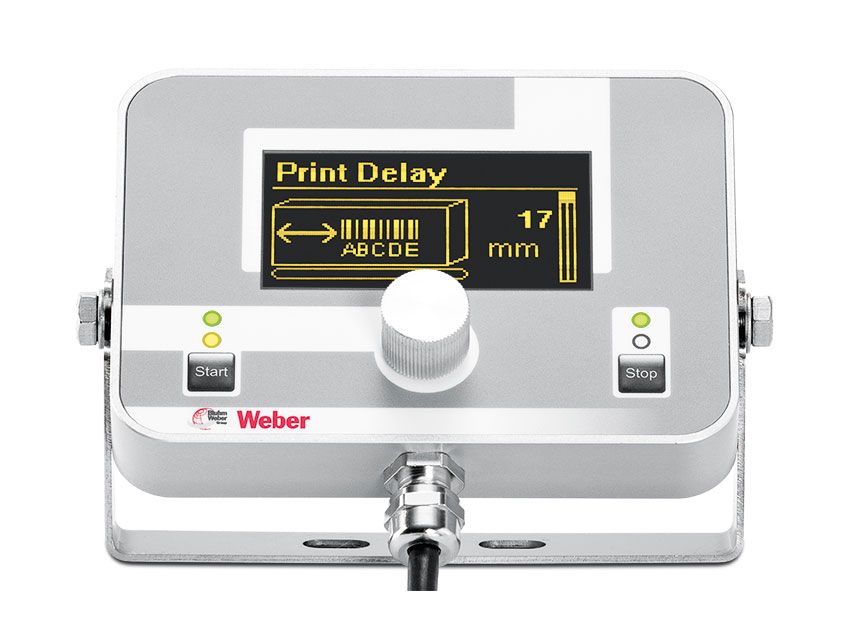

The Markoprint X1JET XR prints up to 71 mm high. It prints with high contrast and precision on flat, absorbent and slightly absorbent surfaces, such as carton. The piezo inkjet printer realises the large character printing required in many industries without offset and prints high-resolution text, 1D barcodes, 2D codes and graphics. This makes it ideal as a labeling alternative. On request, the Markoprint X1JET XR can also print very small, with a minimum print height of two millimetres.

The compact and economical system is particularly suitable for the food, chemical and building materials industries. It impresses with its simple integration into packaging systems and conveyor lines.