BASF

BASF manufactures additives, among other things, at its site in Lampertheim. BASF has relied on Bluhm Weber Group for labelling technology for many years. BASF Lampertheim GmbH was founded in 1962 as Deutsche Advance Produktions GmbH and has been part of the BASF Group since 2009. ‘We needed to modernise here at the site, so we invested in a new packaging centre,’ explains Dr. Jan Eberhardt, Plant Manager at the LIFE plant in Lampertheim.

Products

BASF implements next generation of labelling systems

‘We can control and monitor all Bluhm Weber Groups devices installed here in the packaging centre from our PCs,’ explains Christoph Glab.

It is not only skin that needs protection from sunlight. Light protection is also available for plastics. Additives are mixed into plastics to ensure that they retain their stability despite intense sunlight. BASF manufactures these additives at its site in Lampertheim. BASF has relied on Bluhm Weber Group for its labelling technology for many years. BASF Lampertheim GmbH was founded in 1962 as Deutsche Advance Produktions GmbH and has been part of the BASF Group since 2009. ‘We needed to modernise here at the site, so we invested in a new packaging centre,’ explains Dr. Jan Eberhardt, Plant Manager at the LIFE plant in Lampertheim.

Challenge

- Automation of packaging processes

- Application of individual print data

- Sharp print image for scanner readability

- Bubble-free application of large labels

Result

- The Legi-Air 4050 E labelling system labels fully automatically

- Retrieval of individual print data via SAP

- Pin-sharp printing thanks to thermal transfer process

- Special ‘slide applicator’ for crease-free labelling

- Fully automated GHS labelling

Bluhm Weber Group label a wide variety of containers at BASF – from sacks and drums to pallets. ‘We wanted to completely automate the packaging processes in the new packaging centre,’ reports Christoph Glab, Production Manager Technology and responsible for the packaging centre. Since then, the freshly filled and sealed metal drums have been labelled fully automatically with several labels. In addition to the GHS label with the corresponding hazard symbols, this also includes the product information label.

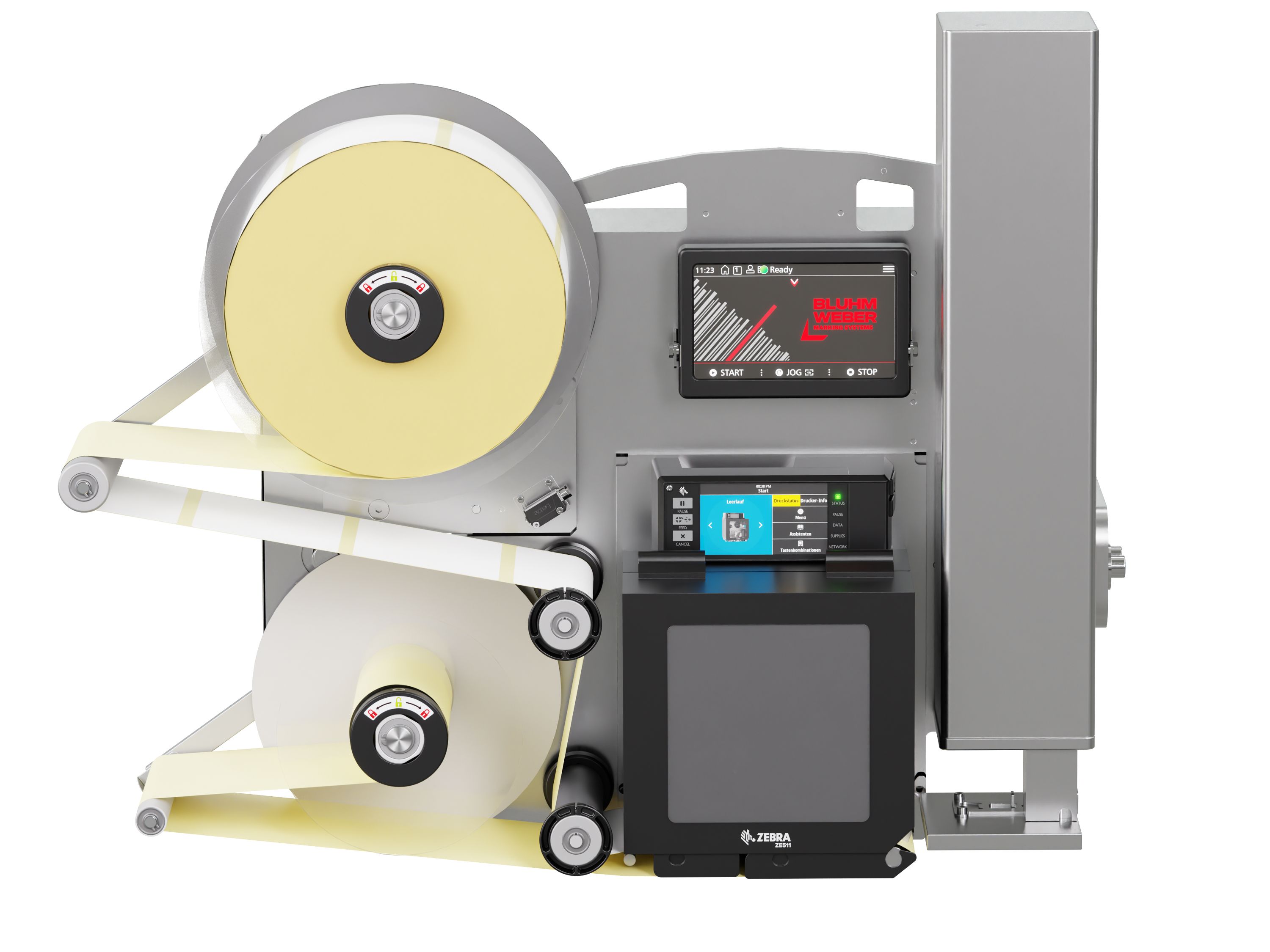

The Legi-Air 4050 E labelling system receives the individual print data via SAP. The information includes data such as contents, weight, hazardous substance information, safety instructions and a data matrix code. The label printer uses a Zebra print module that prints the label material using thermal transfer immediately before dispensing. The print result is correspondingly sharp. This is also necessary because the label is automatically scanned for legibility and plausibility immediately after being applied to the product surface.

Bubble-free drum labelling

The challenge in drum labelling is to apply the long labels along the round surface without bubbles. Round products are normally rotated with the aid of a winding belt for labelling, ensuring that the labels are applied without creases. However, it was not possible to rotate the 200-litre drums at BASF. The experts at Bluhm Weber Group have therefore developed a special applicator that reliably wraps the long and therefore rather unstable barrel label around the curve. This ‘slide applicator’ moves easily towards the barrel advancing on the conveyor belt, then moves precisely along its contours and wipes the label onto the surface without air bubbles.

A robot arm then lifts the drums from the conveyor belt onto the pallets. After the stack of drums has been wrapped with stretch film, the pallets are labelled. A Bluhm Weber Group machine is also used here. The applicator arm of the pallet labeller moves out to the pallet,

Central monitoring and control

‘We can control and monitor all Bluhm Weber Group devices installed here in the packaging centre from a PC,’ explains Christoph Glab. The Bluhmware software developed by Bluhm Weber Group clearly displays the device status of each individual labelling system. For example, you can see at a glance which labeller is currently labelling, which order it is processing and when consumables need to be refilled.