Beck packing machines

Beck Packautomaten GmbH & Co. KG, based in Frickenhausen near Stuttgart, specialises in the fully automatic packaging of a wide variety of products in film and paper. To make its packaging systems even more user-friendly and sustainable, Beck Packautomaten has now developed a new machine concept. An important component is a label printer from the labelling supplier Bluhm Weber Group.

Products

Contactless labelling of uneven surfaces

‘Our new machine concept not only features a new design, but also many new features. Thanks to contactless labelling, the uneven surface of the film packaging is no problem for the labeller.’ - Mark Hübsch-Dolde, Head of Electrical Engineering.

The challenge

- Diagonally running film web must be provided with shipping labels

- Uneven surface of the film packaging

- High-performance, fully automatic system

The result

- Label dispensing stamp mounted at the correct angle

- Contactless inflation of the label onto the surface

- Fully automatic label dispenser for excellent printing and fast labelling in continuous operation

‘Sustainable and flexible film packaging is particularly interesting for mail order companies,’ says Alexander Deharde, Sales Manager at Beck Packautomaten. ’Our new machine concept not only features a new design, but also many new features.’ For example, the bag size of the shipping packaging is adapted to the product in order to achieve the highest possible level of resource and cost savings. At the same time, the system processes an 80% PCR film. This material consists of 80 percent post-consumer recycled products. A label dispenser from Bluhm Weber Group automatically applies shipping labels to the units.

Determining shipping information

For packaging and labelling, the textiles are placed individually or in stacks on a conveyor belt. The corresponding delivery note with barcode is placed upside down under the product. A scanner located under the belt scans the barcode on the delivery note and sends the data to the ERP system. Here, the shipping address for the shipment is determined and transmitted to the Legi-Air 4050 E label printer. Based on this data, the system prints a shipping label.

Contactless labelling

Meanwhile, the products continue to move between film webs located above and below the conveyor belt. Before the film is applied, the labeller applies the shipping label to the upper film web. Since the web runs at an angle downwards, the dispensing stamp was also mounted at an angle. The stamp dips down and blows the shipping label onto the film without touching it. ‘Thanks to contactless labelling, the uneven surface of the film packaging is no problem for the labeller,’ explains Mark Hübsch-Dolde, Head of Electrical Design at Beck Packautomaten.

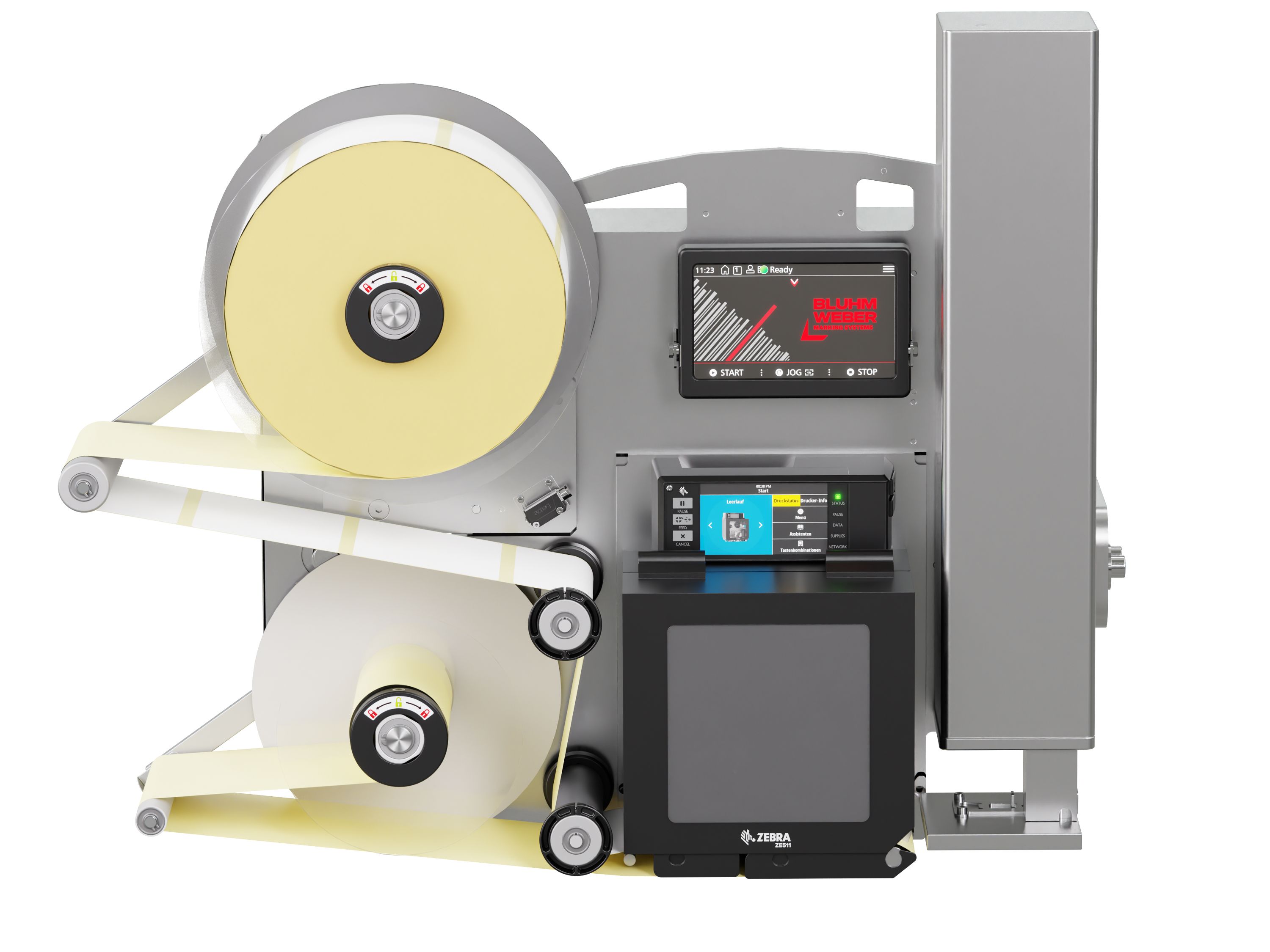

The label printer is designed for continuous operation and is therefore particularly suitable for labelling shipping units. However, it can also be used to label other products such as cartons or pallets. The system can control print modules from all leading manufacturers and thus print labels with a resolution of up to 600 dpi. A Zebra print module has been integrated at Beck, which can print shipping labels at a speed of more than six millimetres per second. In addition to its rapid printing, the system can also label at lightning speed: it can apply up to 80 labels per minute to product surfaces.

Carriage for convenient handling

A large label supply roll of up to 450 running metres ensures high availability. Nevertheless, the Legi-Air 4050 E was mounted on a pull-out carriage in the Beck system for convenient handling. The label printer is controlled via Bluhm Weber Groups own Bluhmware software, which allows the system to be easily networked with a wide variety of ERP systems.

After labelling, the film is sealed lengthwise and crosswise to form a shipping bag. ‘This individual adaptation to the product size not only saves film and thus resources, but also costs and, of course, shipping costs,’ says Alexander Deharde happily. After labelling, the shipping units continue to the end of the system and are transferred from there to the downstream conveyor system. The Beck system packs and labels up to 20 units per minute in this way.