Continental

In order to promote the sale of resource-efficient motor vehicle tyres, the European Union enacted the Tyre Labelling Regulation EU 1222/2009 at the end of 2012. To enable fully automatic labelling of tyres, Continental Reifen Deutschland GmbH has teamed up with labelling specialist Bluhm Weber Group to develop a tyre labeller.

Products

Labelling specialists develop tyre labellers

‘The development of the system was a major challenge for all of us. Therefore, only professionals came into question for a collaboration. The solution developed together with Bluhm Weber Group with the Legi-Air tyre labeler is perfectly adapted to our requirements!’ - Alain Hoff, Plant Operation Manager at Contintental

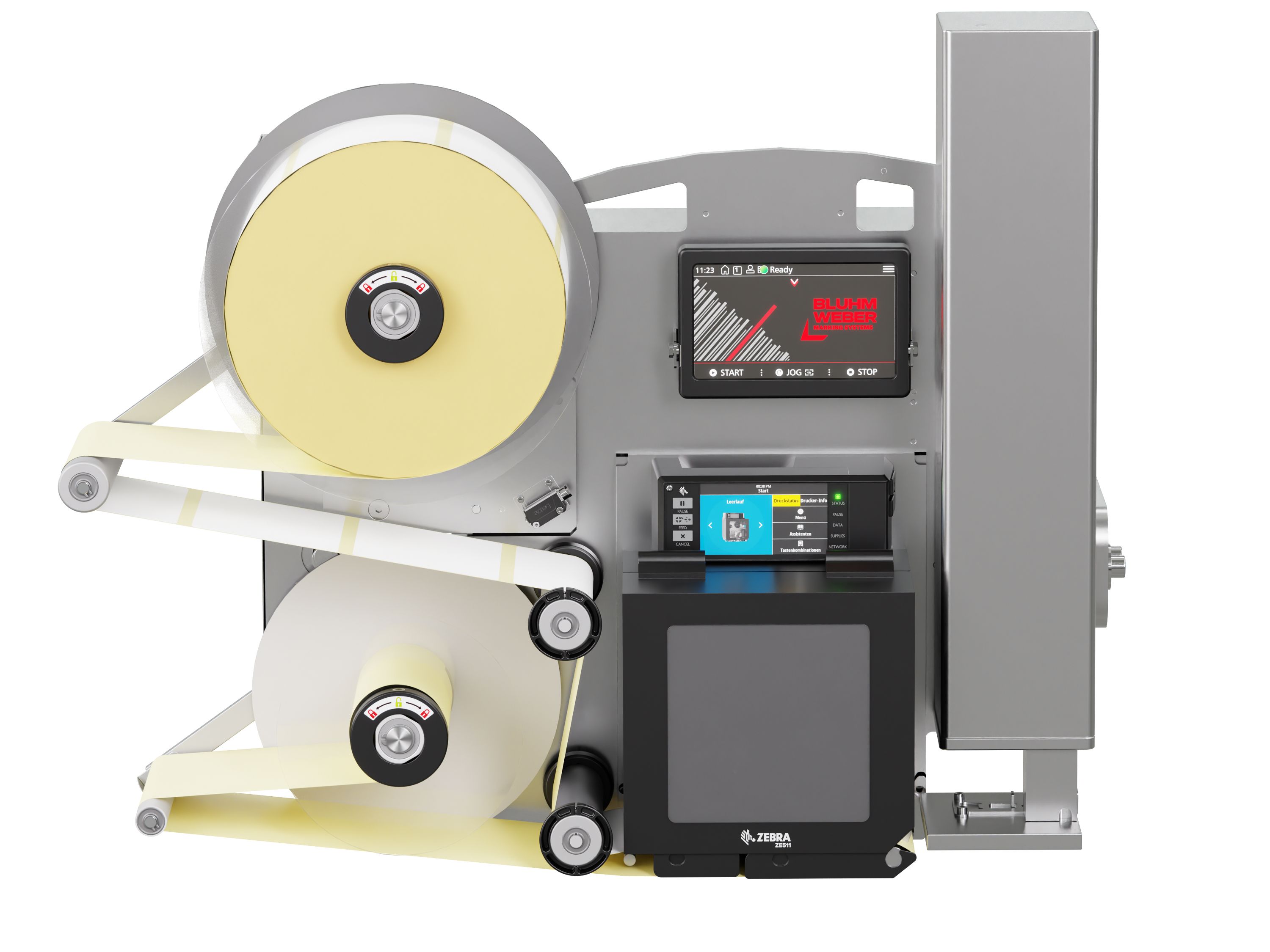

Implementation of the EU Labelling Directive

In order to promote the sale of resource-efficient motor vehicle tyres, the European Union enacted the Tyre Labelling Regulation EU 1222/2009 at the end of 2012. Since then, the EU tyre label has been mandatory, showing the fuel efficiency class, wet grip class and external rolling noise class. In order to be able to label tyres fully automatically, Continental Reifen Deutschland GmbH has developed a tyre labeller in collaboration with labelling specialist Bluhm Weber Group: the Legi-Air Tyre (now Legi-Air 4050E).

Special features

Choosing the right label material was not necessarily easy: stickers do not adhere well to rubber by nature. In addition, due to the production process, tyres are not free of chemical residues and release agents. A particularly strong rubber adhesive was therefore used in the label production at Bluhm Weber Group. A sophisticated material and adhesive solution ensures that the labels can be punched, printed and processed in a labelling system without any problems despite their specific properties.

Intelligent goods dispatch

The labelling system identifies the tyres arriving in random order, records them and prepares them for dispatch. Thanks to barcode labels and SAP integration, the system not only ‘knows’ which tyres need to be labelled with which labels and in which position, but also which delivery vehicles need to be loaded with which items later on. The system processes 10.5 million tyres per year and reduces picking and shipping errors to zero.