Eisbär Eis

Eisbär Eis GmbH was founded in Plummendorf in 1992. Its customer base quickly expanded from regional buyers to national and later European food retailers. Today, over 18 million litres of ice cream are produced here every year. Despite its expansion, Eisbär is still family-owned. Just like its supplier of marking technology: several systems from Bluhm Weber Group mark Eisbär products at various stages of the production process.

Products

3 different marking systems from Weber Marking Systems in use

‘The devices label very reliably and are highly valued by our employees. So it was only natural to turn to Bluhm Weber Group when we needed to expand our portfolio!’ - Martin Esch, Technical Manager, Eisbär GmbH.

The challenge

- High printing speed and production reliability

- Ambient temperature of -6 to -10 degrees Celsius

The result

- Continuous monitoring of ink and solvent levels by Linx 8920

- The Legi-Air 4050E labelling system labels passing products without contact

- Air-conditioned housing for Legi-Air 4050P

Continuous inkjet printing on product packaging

The product packaging for the various ice cream flavours must be marked with best-before dates and lot and batch numbers. Eisbär uses a Linx 8920 continuous inkjet printer for this purpose. The device is capable of printing more than 2,000 characters per second. The print image can be divided into up to four lines of text. In addition to this high printing speed, the Linx 8920 offers the particular advantages of ease of use and high reliability. Production reliability is achieved not least thanks to its continuous monitoring of ink and solvent levels. A sensor in the printhead also continuously measures the viscosity of the ink and adjusts it automatically if necessary. If a specific coding speed is stored, a red or green screen background indicates whether this specification is being met or exceeded.

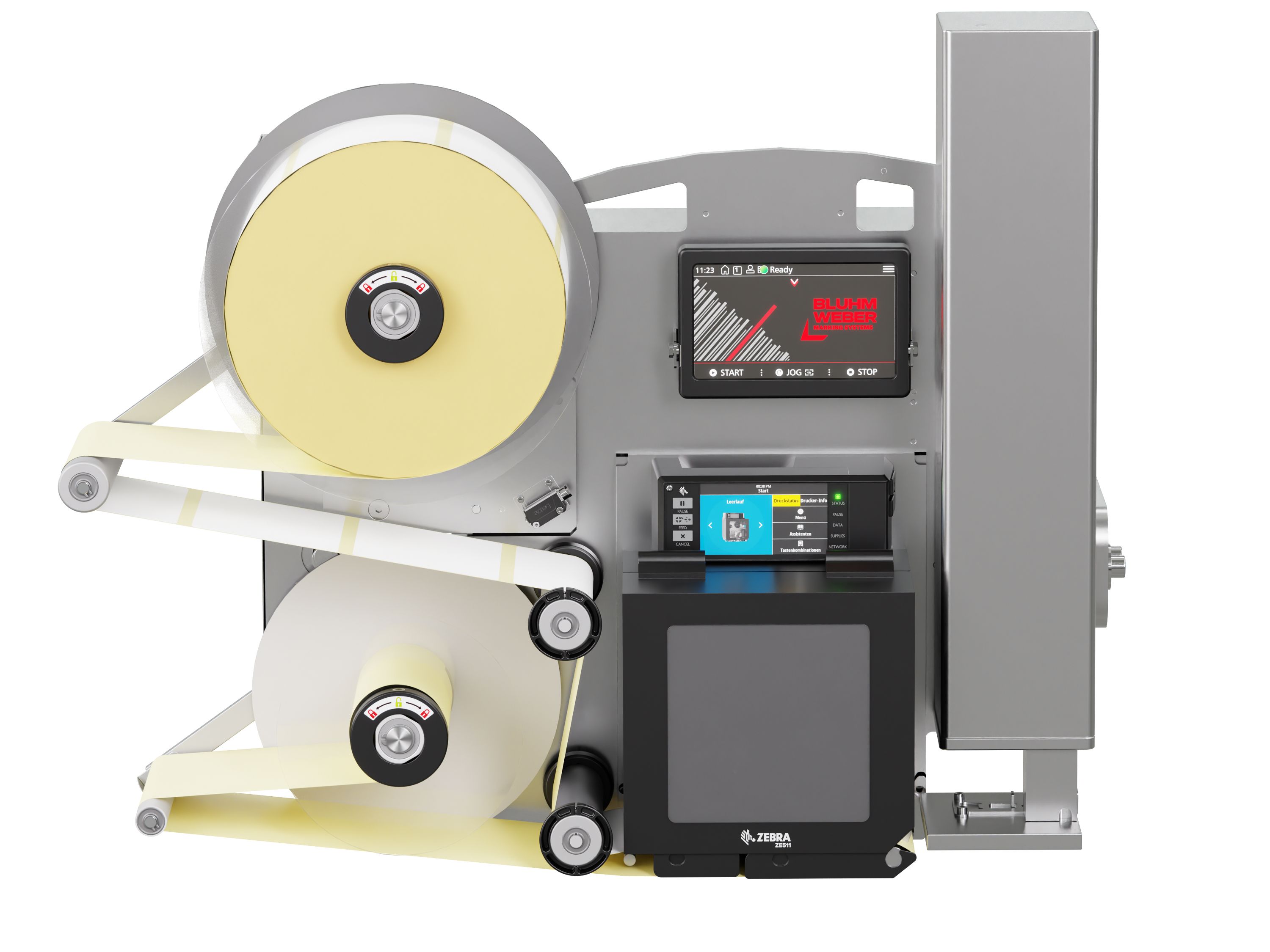

Labelling of outer cartons

After the product packaging has been labelled, a packing system sorts the units into outer cartons. ‘The outer cartons are assembled individually according to customer requirements – we are very flexible in this respect,’ says Martin Esch. To prevent mix-ups, the cartons are then labelled immediately: The Legi-Air 4050E labelling system from Bluhm Weber Group marks each individual carton with information about its contents and the customer. For this purpose, the system was equipped with a Novexx DPM print module and a 90° rotary applicator.

Pallet labeller: GS1-compliant, air-conditioned and protected

The ambient temperature at the palletising station ranges from minus six to minus ten degrees Celsius. The Legi-Air 4050P pallet labeller is therefore housed in an air-conditioned enclosure. As soon as a freshly wrapped and therefore label-ready pallet approaches, the label printer prints the information transferred from the ERP system onto a pallet label and pushes it onto the dispensing stamp. Once the corresponding pallet is in position, a pneumatic sliding window in the labelling housing opens, clearing the way for the dispensing stamp. The stamp extends, labels the passing pallet on the front and immediately retracts. As the pallet continues to move, the print module pushes another label onto the dispensing stamp. The applicator extends again, labels the pallet on the side and disappears back into the housing. The sliding window closes and the pallet continues on to the high-bay warehouse. The Legi-Air 4050P is equipped with numerous safety features. To protect against accidents in the event of a power failure, the swivel arm is designed so that a passing pallet would not damage it, but merely push it to the side. This technology has been patented by Bluhm Weber Group.