H. Wilhelm Schaumann

For more than 80 years, Schaumann has been dedicated to feeding farm animals such as pigs, cattle and poultry. To avoid confusion, all feed bags are labelled with product information and one- and two-dimensional codes before filling.

Products

State-of-the-art technology for the most demanding requirements

‘Process reliability has always been a top priority at Schaumann. In addition, high-quality QR code printing had to be implemented across a large area on a horizontal paper bag. Plus labelling with a DIN A5 format label. By updating the marking system, we have taken a major step forward in the automation of warehouse logistics!’

The challenge

- Large-area QR code printing

- Labelling in A5 format

- No coding possible on the conveyor belt

- Clean print image despite vibrations

- High demands on ink in the food industry

The result

- Integra PP 108 prints individual QR codes with a height of 108 mm and a resolution of 360 dpi

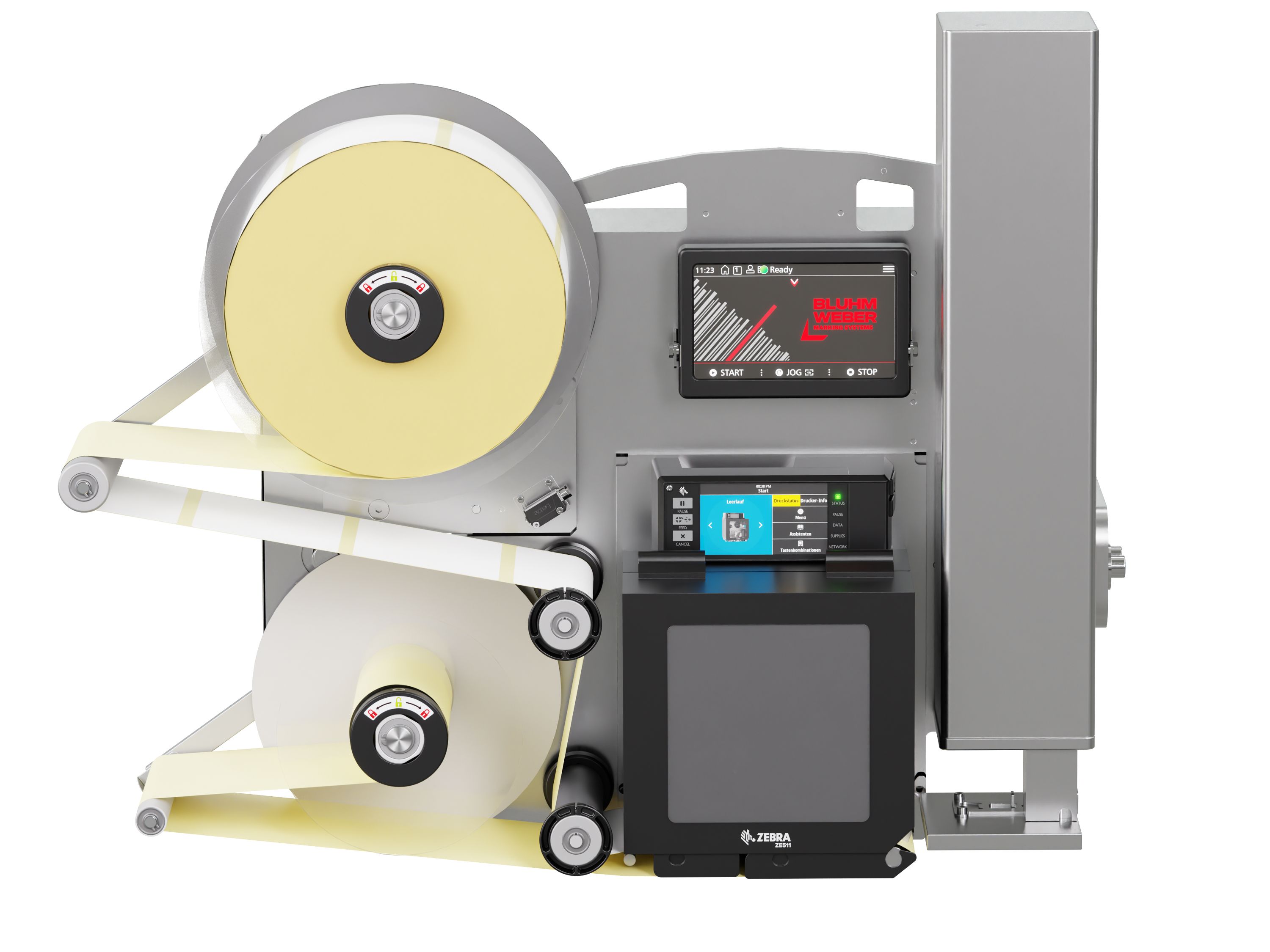

- The Legi-Air 4050 label printing and dispensing system applies DIN A5 labels without contact

- Mounting the Integra PP 108 on a mobile crossbeam

- Recirculating ink system ensures a brilliant print image even with vibrations

- Certified, mineral oil-free ink for safe marking

Marking technology for process reliability

‘Our old marking solution was getting on in years,’ explains Stefan List. Spare parts were becoming obsolete and service could no longer be guaranteed. Schaumann produces around the clock using a just-in-time process. “We can't afford production downtime or delays. That's why we looked around for new technology,” says Stefan List. He found what he was looking for at the marking supplier Bluhm Weber Group. System consultant Alexander Wimmer emphasises: ‘Process reliability was and is the top priority at Schaumann. In addition, high-quality and large-area QR code printing had to be implemented on a horizontal paper bag. Plus labelling with a label in DIN A5 format.’

Alexander Wimmer recommended the Markoprint Integra PP 108 inkjet printing system to Stefan List. This is because it not only prints large, fast and in high resolution, but is also resistant to vibrations. ‘Inkjet printers normally code products that move past them on a conveyor belt,’ explains Wimmer. However, as Schaumann's unfilled paper bags were not to be transported on a conveyor belt, the printing system had to be ‘set in motion’. Bluhm Weber Group mounted the PP 108 on a crossbeam that moves sideways so that the printhead can print on the paper bags as it moves sideways. ‘There was a lot to consider during installation, of course,’ recalls Alexander Wimmer: ’Hoses and cables had to be out of the way and the print head had to be able to withstand the vibrations caused by the movement.’ Perfect conditions for the Integra PP 108: even with vibrations, the recirculating ink system ensures that no nozzles fail and the print image remains brilliant at all times. Even a blow to the housing does not affect the printer.

Automation of warehouse logistics

‘With the new labelling solution, we also wanted to automate our logistics to a certain extent,’ emphasises Stefan List. In addition to plain text, an automatically readable QR code was to be applied to the bottom of the bags. ‘Each bag receives an individual code. This not only simplifies our logistics processes, but also ensures the traceability of our products,’ says List: ‘Because we want to know at all times who produced what, when, where and with which raw materials from which supplier!’

The Integra PP 108 prints the individual QR codes at Schaumann at a height of 108 millimetres and a resolution of 360 dpi on the paper bags. With up to 150 metres per minute, it also works at an above-average speed. This corresponds to the rapid speed of 2.5 metres per second. Its certified, mineral oil-free ink also meets the high requirements of the food industry. It can therefore be used without hesitation for labelling products and packaging in the food sector. The print images can be conveniently created on a PC using the supplied idesign8+ software and transferred to the printer. For safety reasons, the current print image is also always visible on the printer display.

Labelling in DIN A-5 format

Immediately after printing, the paper bags are labelled. This label contains product-specific information such as article and product names, ingredients, brand labels and several barcodes. Due to the wealth of information, a DIN A-5 format label is required. It is applied by a print dispensing system from Bluhm Weber Group. The Legi-Air 4050 receives its print information from the customer's network and forwards it to the manufacturer Zebra's print module installed in the system. The freshly printed label is immediately applied to the paper bag by the dispenser without contact. Here, too, high speeds are possible.

After labelling, the paper bags are filled with the appropriate feed and sealed. Stacked on pallets, they are transported to the warehouse by forklift. Thanks to the size of the QR codes on the bottom of the bags, the contents of the feed bags can be easily determined by scanning from the forklift. ‘With the update of the marking system, we have taken a big step forward in the automation of warehouse logistics,’ says Stefan List happily.