Meraner Mühle

The Meraner Mühle mill in Lana, South Tyrol, processes over 20 different types of grain. The family-owned company looks back on a tradition spanning more than 600 years. The mill labels its products individually for its diverse customer base, which includes bakeries, industry, wholesalers and retailers, using several labellers from the labelling supplier Bluhm Weber Group.

Products

High-precision marking for a wide range of products

‘We have to label foil-wrapped pallets and big bags at different heights. That's why Bluhm Weber Group mounted the pallet labellers on height-adjustable stands.’ - Sebastian Obrist, Head of Technology.

The challenge

- Abrasion-resistant printing on pallets and big bags

- Marking of pallets on different sides

- Dusty production environment in the mill

The result

- Gluing of pallet feet

- Over 900 bags per hour

- Scanning of codes for quality control

- Perfect printing results guaranteed

‘We are particularly proud of the processing of regional grain,’ explains Armin Oberhollenzer, Marketing Manager at Meraner Mühle. The “zero-kilometre grain” is grown, milled and sold in South Tyrol. Meraner Mühle has been promoting this project, which is close to its heart, for more than ten years. The products are filled into bags at the Lana site. As a result, pallets and pallet feet must also be labelled in addition to bags and cartons.

Bag labelling

Meraner Mühle's bagging machines produce around 900 bags per hour. ‘The flour bags must then be labelled with best-before dates, LOT numbers, product descriptions and bilingual processing instructions,’ explains Production Manager Sebastian Obrist.

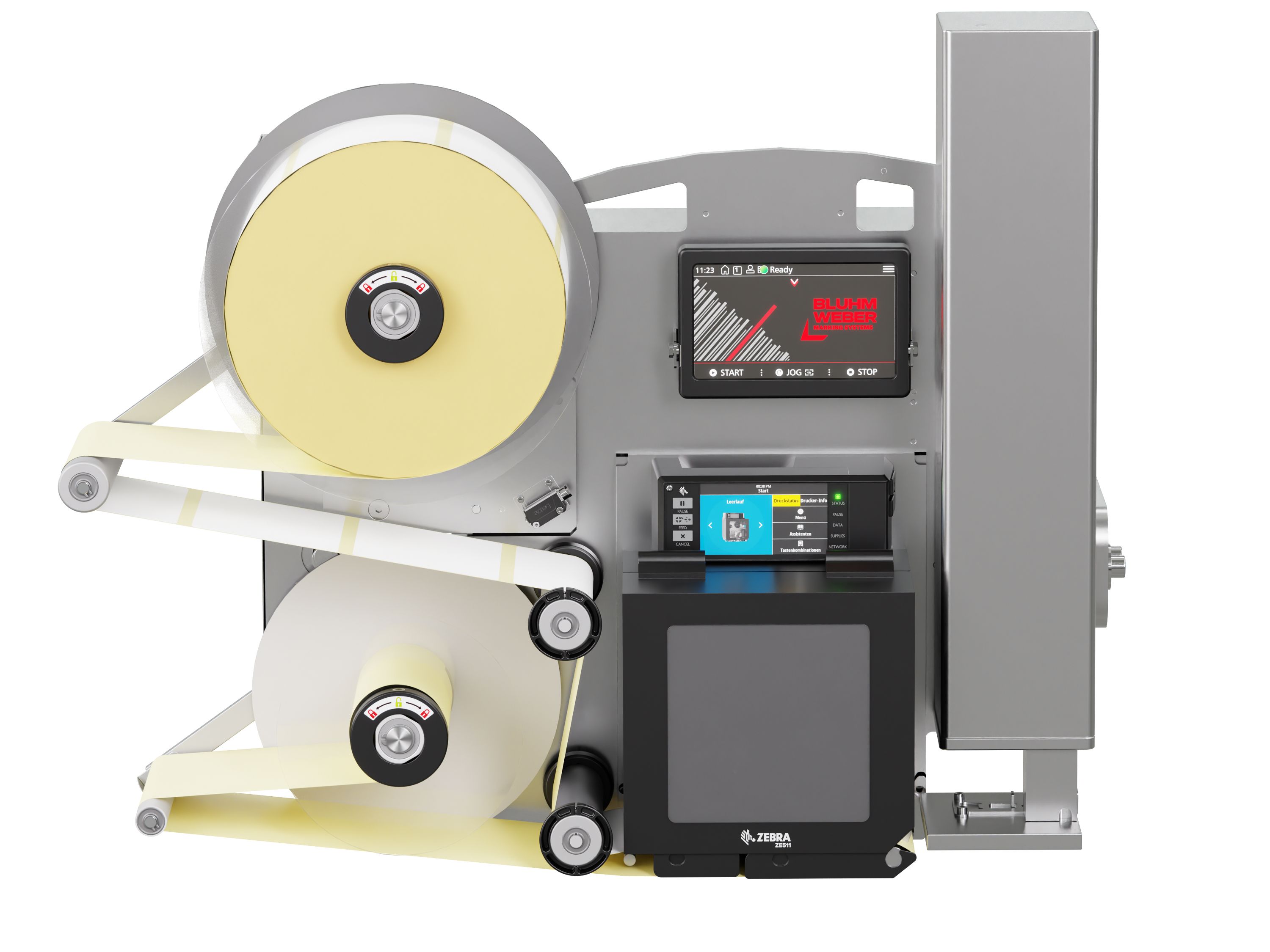

This task is performed by a Legi-Air 4050 E labeller from Bluhm Weber Group. The integrated print module prints the label with individual data and pushes it onto the dispensing stamp attached to the lower end of the dispensing stroke. As the flour sacks pass through the labelling system, the dispensing stroke extends and automatically determines the product height. It stops a few millimetres above the cardboard box and blows the label onto the uneven surface without touching it.

Pallet marking

At the palletising station, foil-wrapped pallets and big bags have to be labelled at different heights. ‘That's why Bluhm Weber Group mounted the pallet labelers on height-adjustable stands,’ says Sebastian Obrist enthusiastically.

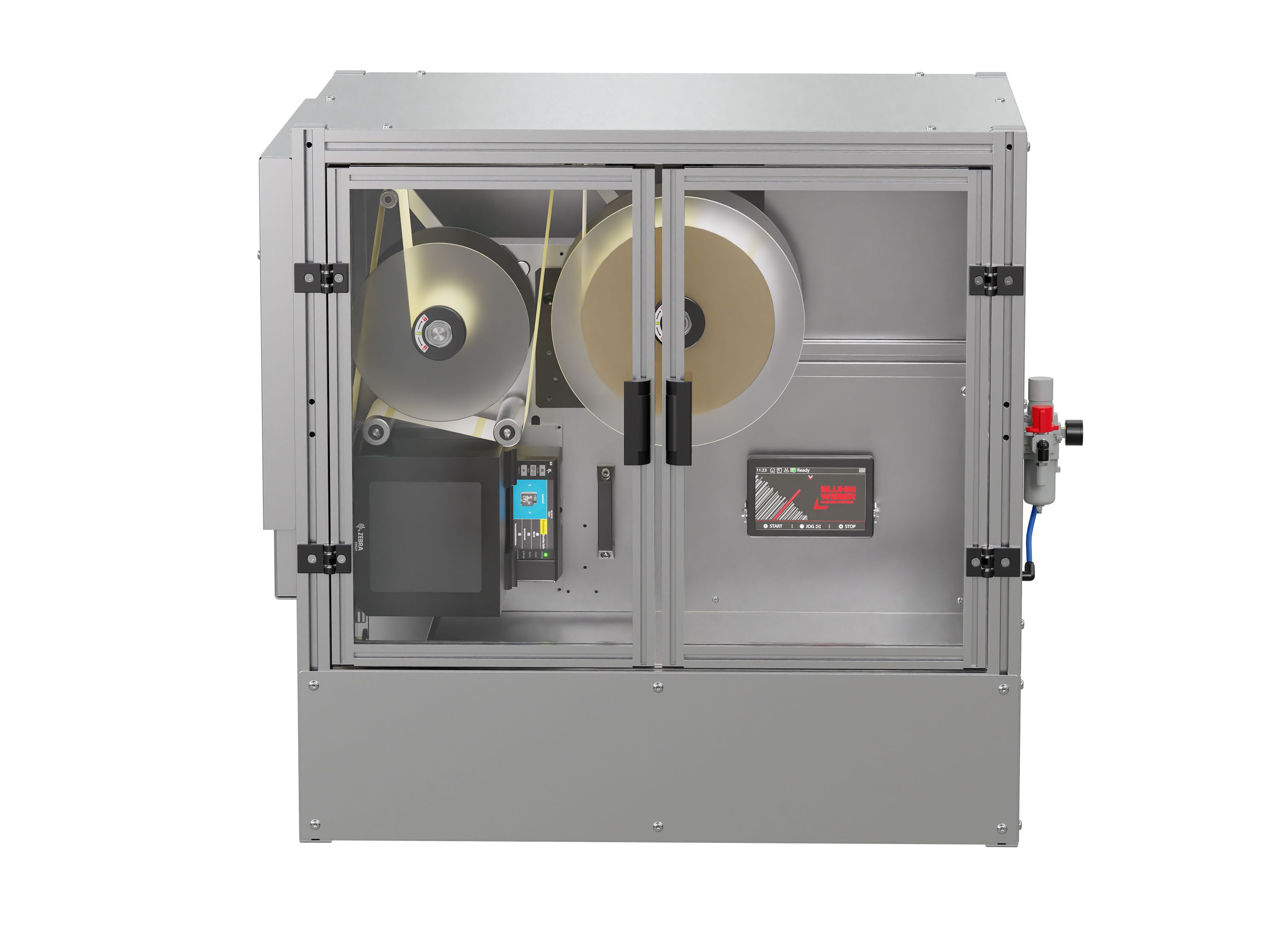

These pallet trucks move up and down at a speed that does not require protective barriers. And thanks to their intrinsically safe design, the labelers themselves do not require any protective fences. Completely enclosed and equipped with automatic shut-off slides, they are well protected against the dusty production environment of the mill.

The pallets are labeled individually according to customer requirements and destination. Some pallets need to be labelled with two different labels on one side, some GS1-compliant on two adjacent sides, and others on three different sides. The smart AP 182 ensures that this can be done on the same packing line. It can be triggered individually from each pallet and activates a corresponding movement profile. It achieves top speeds of 120 pallets per hour for two-sided labelling and 90 pallets per hour for three-sided labelling.

Pallet base labelling

At its site in Lana, Meraner Mühle operates a fully automated high-bay warehouse with over 8,000 pallet spaces. Since damaged Euro pallets can cause problems during storage, all pallets must be checked in advance at the pallet inspection station. During the inspection, they are weighed and assigned an item number. The ERP system encrypts this data into a QR code and two barcodes. These codes are attached to the pallet base so that they can be read at any time later in the warehouse.

This task is performed by a Legi-Air 4050B-Electrical Swing labelling device. It has a swivel arm that can be rotated 90 degrees in front of the pallet, making it particularly convenient for front-side labelling. As an ‘all-electric device’, it does not require any costly compressed air.

Since labels adhere less well to wood than to other surfaces, Bluhm Weber Group recommended a special solution: for particularly reliable labelling, the base is first sprayed with glue. The labeller then applies the label. For control purposes, a camera immediately scans the codes on the labels: zero tolerance for zero-kilometre grain.