Asset Tracking

Asset Tracking enables companies to monitor and document the storage, delivery and production of tangible assets in real time and to incorporate them into process planning. Fixed, variable or even individual data can be read.

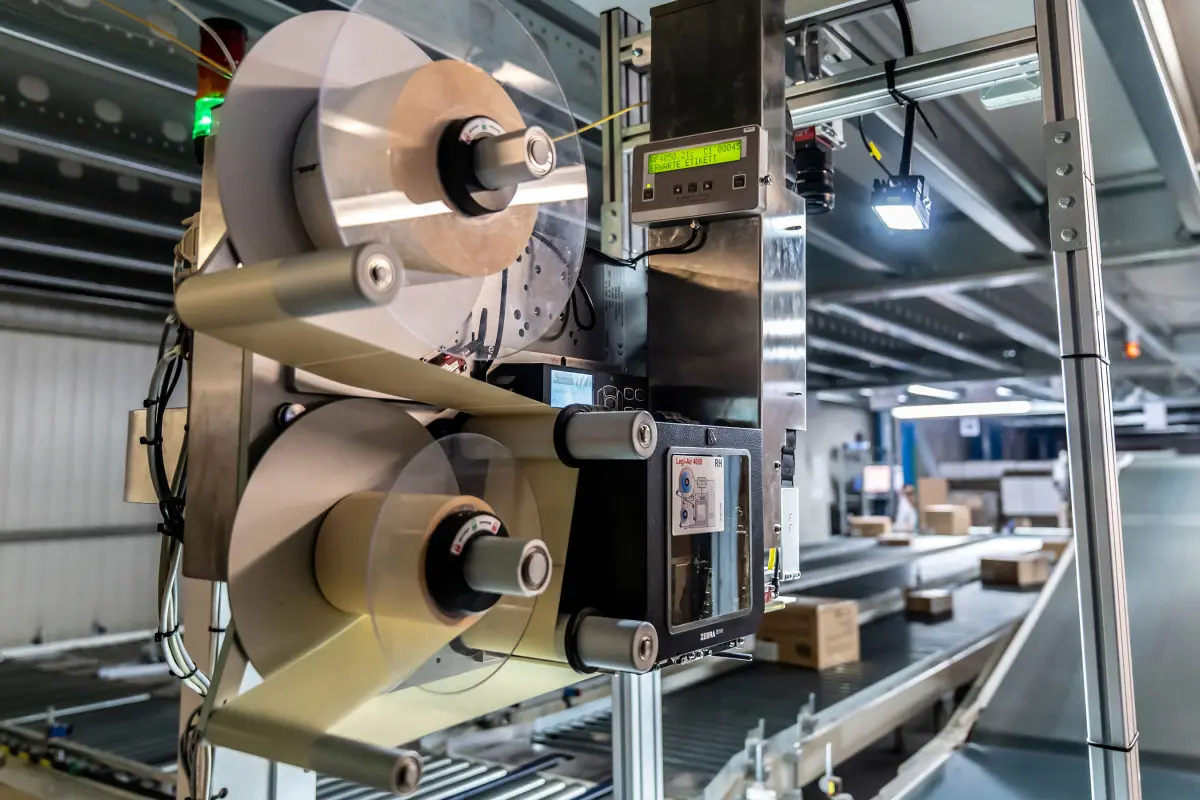

This product labelling is either printed directly on an object (by ink or laser) or indirectly coded on a carrier material such as labels. Asset tracking is an essential part of industrial automation through networking with existing systems.

Advantages of asset tracking

Transparent overview in real time

The location, status and other information about assets can be tracked and documented. The (real-time) data can also be used to automate and optimise processes. Asset tracking also provides an overview of which resources and operating materials are unused. Via sensors or tags, asset tracking indicates the status with regard to storage, location, condition or durability.

Identify untapped potential

The use of asset tracking reduces errors and reveals untapped potential, while simultaneously increasing the speed of individual processes in the company. The data can also be used seamlessly to automate processes. Only with complete transparency in production and logistics can time and money be saved and processes optimised.

Real-time monitoring and alerting through labelling

Asset tracking monitors movement data, load carriers, pallets, equipment or fill levels and triggers an alarm if necessary. In connection with camera systems, asset tracking also provides visual data, e.g. where goods are lost, damaged or stolen.

Proactive avoidance of downtime

Downtime in production and logistics can be significantly reduced by asset tracking, for example, by indicating maintenance intervals and providing timely warnings about when to replace, dispose of, modernise, etc.

View utilisation and availability

Asset tracking provides a precise overview of the availability of machines, storage locations and buildings. In addition to non-operational devices, operational devices or available storage locations are also displayed.

Barcodes

A barcode (also known as a universal product code, UPC) is a machine-readable arrangement of numbers and parallel lines of different widths.

Advantages of barcodes and barcode labels:

- Can be used flexibly (small to large formats)

- Easy to create

- Inexpensive to produce

- Readers are widely used

- Proven and well-known technology

QR codes

A QR code (Quick Response Code) is a pattern of black and white squares. It can be read by smartphone or tablet and enables large amounts of information to be encoded.

Advantages of the QR code:

- Bundles more information than a barcode

- Easy to create

- Inexpensive to implement

- Proven and well-known technology

- Readable via tablet or smartphone

Data Matrix Codes

Data Matrix codes are – like QR codes – two-dimensional barcodes that encrypt data in the form of a surface over two directions. They can encode a large number of characters in the smallest of spaces. This means that they can also be used on the smallest of products or round surfaces.

Advantages of Data Matrix codes:

- higher data density than other barcodes

- better readability with lower contrast

- can be scanned in any position

- high error tolerance of up to 30 per cent

RFID

Radio Frequency Identification is a technology that uses small computer chips to track objects from a distance.

Advantages of RFID systems:

- No visual contact between transmitter and receiver necessary

- Can be attached invisibly

- Real-time detection

- Bulk detection

- Also serves as theft protection

- Insensitive to soiling

Weber Marking Systems' RFID systems can test the programmed RFID chips before application and automatically sort out any defective RFID labels using a bad tag reject unit. This brings security to logistics and reduces downtime costs.