Automatic Identification and Data Capture (AIDC)

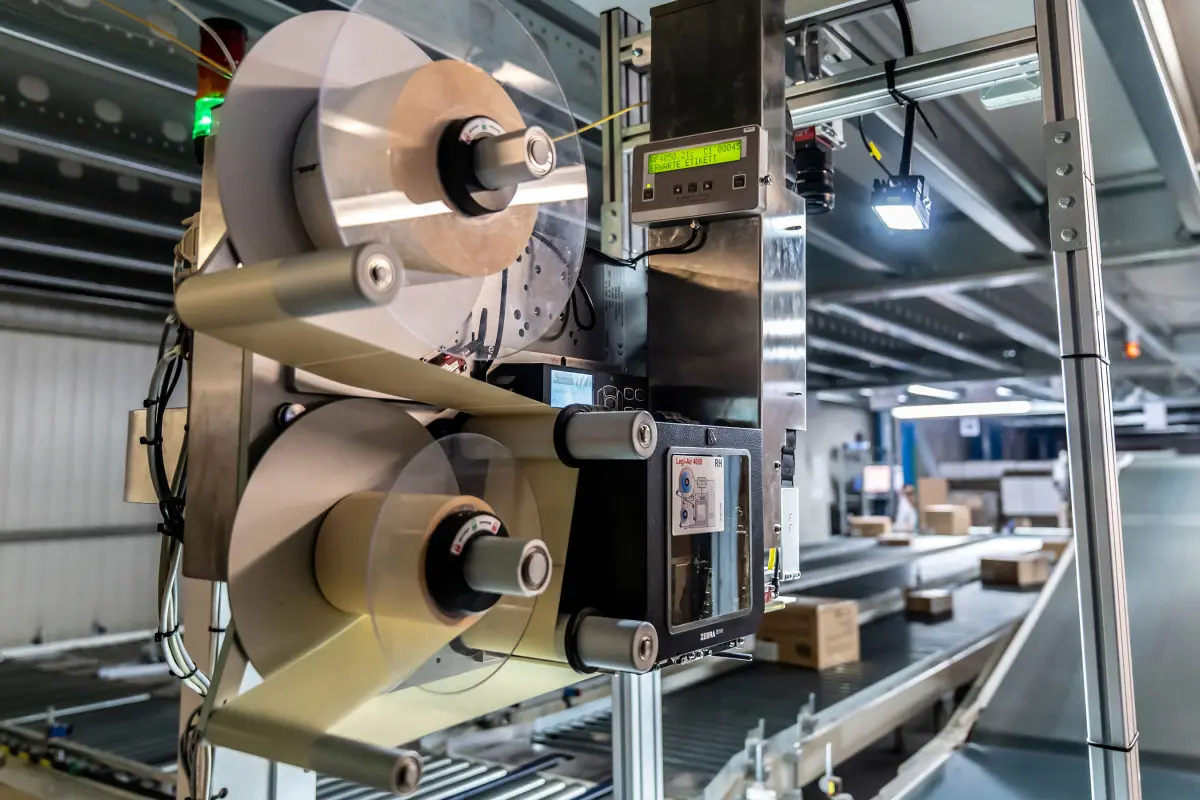

Automatic Identification and Data Capture (AIDC) is an essential factor in global trade and industrial automation. In logistics, smart ID technologies accelerate numerous processes for identification, data collection, data processing and data networking.

What is AIDC?

AIDC is a technology that allows objects to carry machine-readable information in the form of a code. Electronic devices such as barcode scanners or cameras can read and process this information. A well-known example is scanning a barcode on a product at the supermarket checkout.

Advantages of AIDC

Important advantages of using AIDC systems are:

- real-time insights into the supply chain

- tracking (track and trace) of a product along the entire supply chain

- documentation of production and shipping processes, material flows or transport and storage routes

- records of delays, damage or tampering

- streamlining of administrative work

- reduction of errors that can occur through manual transmission

Auto-Ident Technologies

An Auto-Ident system uses automatic identification technologies such as barcodes, data matrix codes, GTIN, RFID technology or QR codes. The system collects the data using sensors and transmits it to a database. There they are analysed and used for various applications such as inventory management, supply chain tracking or access control. The specific way an Auto-ID system works depends on the type of technology used.

Biometric systems

Biometric systems are divided into acoustic and optical methods. These include, for example, voice recognition, fingerprints or faces. Biometric recognition systems use physical characteristics such as fingerprints or facial recognition for identification and are used in security and access control applications.

Electronic methods

Electronic methods are, for example, magnetic cards or RFID systems. Magnetic cards are used in a variety of areas, often with a contactless or contact chip. Typical applications include ID cards, time tracking, access control, loyalty cards or vouchers.

RFID is commonly used for asset tracking, supply chain management and access control systems because it can identify objects without requiring direct line of sight. It can also collect data from multiple transponders, such as objects on a pallet. An RFID system consists of a transponder and an RFID reader. The transponders or RFID chips are often attached to the products or containers in the form of RFID labels.

Character- or symbol-based methods

With OCR (Optical Character Recognition), such as barcodes, QR codes, GTIN or data matrix codes, texts or characters are read or scanned. These so-called 2D codes are used primarily in retail, logistics and merchandise management.