Unique Device Identification (UDI)

The new Medical Devices Act and the Medical Device Regulation (MDR) stipulate clear and standardised labelling of medical devices with a UDI code (Unique Device Identification).

What does Unique Device Identification (UDI) mean?

Unique Device Identification - UDI for short - is a term that is closely associated with medical devices. It translates as ‘unique device identification’. This is only possible if all medical devices are assigned a unique code that can be used to identify and trace them.

Why was UDI labelling introduced?

Originally, the US FDA, the Food and Drug Administration, developed this procedure and introduced the so-called UDI directive, which provides for the unique labelling of medical devices. The primary aim of UDI is to ensure quality and protect patients.

UDI optimises processes in the healthcare sector and enables

- greater patient safety

- simpler product recalls

- increased protection against counterfeiting

- more efficient logistics processes

- system-wide data and material management

- Fast safety corrective measures

EU Medical Devices Act MDR 2017/745 and MDR 2017/746

How is the UDI code structured?

UDI consists of three basic elements:

- Device Identifier (DI), a static code for article identification

- Production Identifier (PI), which is variable data for traceability such as batch number, serial number and expiry date

- Basic UDI-DI (DI), model number of a medical device group

The regulation stipulates that the Device Identifier (DI) and the Production Identifier (PI) must be applied directly or indirectly to each product or packaging unit in plain text and encoded in a machine-readable barcode, 2D code or RFID chip.

In addition, the manufacturer must store the corresponding product information in the UDI database, which is part of the European database for medical devices EUDAMED. The key to this is the Basic UDI-DI, which must also be included in the manufacturer's declaration of conformity and in the technical documentation. This means that the relevant information and master data for the product can be retrieved at any time in the supply chain.

What are the deadlines for implementation?

The EU Medical Device Regulations MDR 2017/745 came into force on 25 May 2017 for medical devices and on 25 May 2017 for in vitro diagnostics. During a three-year transition period, medical devices can still be certified under the old law.

From 26 May 2021 (medical devices) and 26 May 2022 (in vitro diagnostics), manufacturers must present an EC certificate in accordance with the new MDR when they place medical devices on the market for the first time. To this end, the products must be assigned unique UDI codes and the product information must be stored in the central Eudamed database.

From 2021, the labelling obligation for the individual product classes I to III will follow in stages until 2025. For in-vitro diagnostics, the corresponding deadlines for the individual product classes are 2023 to 2027.

Labelling can generally be carried out using a label or direct marking. With the exception of reusable medical devices such as surgical instruments, where the regulation stipulates that the UDI code must be labelled directly on the device.

| Marking |

Implants and medical devices class III |

Medical devices class IIb |

Class I medical devices |

| Application of labels with UDI code (MDR Article 123(3)(f), Article 27(4)) | 26 May 2021 | 26 May 2023 | 26 May 2025 |

| Direct labelling of reusable medical devices | 26 May 2023 | 26 May 2025 |

26 May 2027 |

| Marking |

Class D in vitro diagnostics |

Class C and B in vitro diagnostics |

Class A in vitro diagnostics |

| Application of labels with UDI code (MDR Article 113(3)(e), Article 24(4)) | 26 May 2023 | 26 May 2025 | 26 May 2027 |

However, there are always special regulations: Some products are subject to additional or different provisions and transitional periods in accordance with Article 120 of the European Medical Device Regulation (MDR).

Which medical device classes are there?

In general, the classification of the various medical devices is primarily based on the potential health risk to humans - not the effectiveness. Medical devices are categorised according to class. Products with the lowest hazard potential are assigned to class I, products with the highest to class III. Class II is further subdivided into a and b. In vitro diagnostic products are divided into groups from A to D.

In the USA, products are already assigned to a class in a database. In the event that a product cannot be found in this database, the highest risk class 3 automatically applies until the FDA downgrades it if necessary. The situation is different in Europe, where rules and certain criteria define the classification.

Classification is based on the following criteria:

- How long does the application or implantation take?

- Where does the application take place? What is the degree of invasiveness? (invasive, surgically invasive, implantable)

- Is the product applied to the central circulatory system, heart or central nervous system?

- Is the device a reusable surgical instrument?

- Is the product an active therapeutic or diagnostic medical device?

- Does the product contain biological material from animals or humans?

Examples of medical technology product classes (not exhaustive)

| Class I | Class IIa | Class IIb | Class III |

|

|

|

|

Examples of in-vitro diagnostics product groups (not exhaustive)

| Group A | Group B | Group C | Group D |

|

|

|

|

Further information on the classification of medical devices can be found on the website of the Federal Institute for Drugs and Medical Devices.

How can the UDI labelling of medical devices be implemented?

Various labelling technologies are available for the implementation of the EU Medical Device Regulation: Ink, laser and labelling. The following questions must be clarified in advance in order to find out which marking system is suitable for the respective application:

- Is it a reusable medical device, such as surgical cutlery?

- What is the material of the product to be labelled?

- Is the surface straight or curved?

- What are the belt speeds during production?

- What information needs to be applied in addition to the UDI code?

- What is the production environment like? Dusty, damp, particularly cold or warm, etc.

In principle, however, there are certain labelling technologies that are particularly suitable for individual products and packaging in medical technology and in vitro diagnostics.

Laser labelling: marking surgical instruments and implants

Surgical instruments are classed as reusable medical devices, which is why no labels are suitable for UDI labelling. The UDI code must therefore be applied directly to the product surface using a direct labelling system. At the same time, the labelling must be permanent and even withstand chemical cleaning cycles and autoclaving.

As medical instruments, cutlery and implants are usually made of titanium or stainless steel, and the latter are sometimes also made of plastic, lasers are the main option for this. This is because laser marking systems mark various materials such as plastics, metals, ceramics or even lacquered cardboard quickly, contact-free and precisely. Another major advantage of laser marking is that it is permanently abrasion-resistant and can withstand any cleaning or sterilisation process. The following three laser labelling processes are used in the medical technology sector:

- Engraving

- Annealing marking

- Colour change

In laser engraving, part of the material melts or vaporises due to the high heat generated by the laser. This creates a clearly perceptible marking on the material surface, which is why it is used wherever deep penetration into the material is required.

In contrast to engraving, annealing marking is gentle on the material. It is often used to mark reusable medical instruments, implants and surgical instruments made of titanium and stainless steel. The materials used in these areas react when exposed to oxygen and heat, causing the upper layers of the material to oxidise and discolour.

A laser can also produce a colour change in numerous plastics used in medical technology.

Both the annealing marking and the colour change do not remove material, nor do they throw it up. This prevents germs and bacteria from settling. Another advantage of laser labelling is that it is corrosion-free and biocompatible.

Inkjet printing: labelling packaging made of plastic film, cardboard or Tyvek®

The Medical Devices Act also stipulates that not only the medical devices themselves, but also the outer packaging must be labelled with a UDI code. Typical packaging materials for medical devices are plastic film, cardboard or Tyvek. Packaging made of plastic or film has a non-absorbent surface. Inkjet printers with fast-drying ink print such materials legibly and durably. The continuous inkjet printers from Linx, for example, are suitable for this. There is a large selection of inks for these systems. They are also easy to operate and stand for high system availability.

If flexible film packaging needs to be printed, this can be done with direct thermal transfer printers such as the Linx TT 10. Thermal transfer printing is a cost-effective alternative to labels. The Linx TT prints texts, logos or barcodes and data matrix codes onto the packaging with a print width of 107 mm and is easy to read.

Materials such as absorbent cardboard or Tyvek®, a non-woven material made from polyethylene, can be easily printed on with thermal inkjet printers. Sterile packaging in the medical technology sector is often made of Tyvek®. This material has special properties: it consists of millions of vapour-permeable microfibres that form a smooth surface. The ink must therefore adhere well to the surface on the one hand, but on the other hand it must not pass through the permeable fibres onto the packaged product. Thermal inkjet printers in combination with fast-drying inks print such materials in high resolution and durably. The thermal inkjet printers in Weber Marking Systems Markoprint series, in combination with inks such as the HP 2590, print information such as the UDI code on such packaging in an MDA-compliant manner. Clean and high-resolution with up to 600 dpi. The print quality is consistently very good, as the ink cartridge is also the print head. This means that the print head is replaced every time the cartridge is changed.

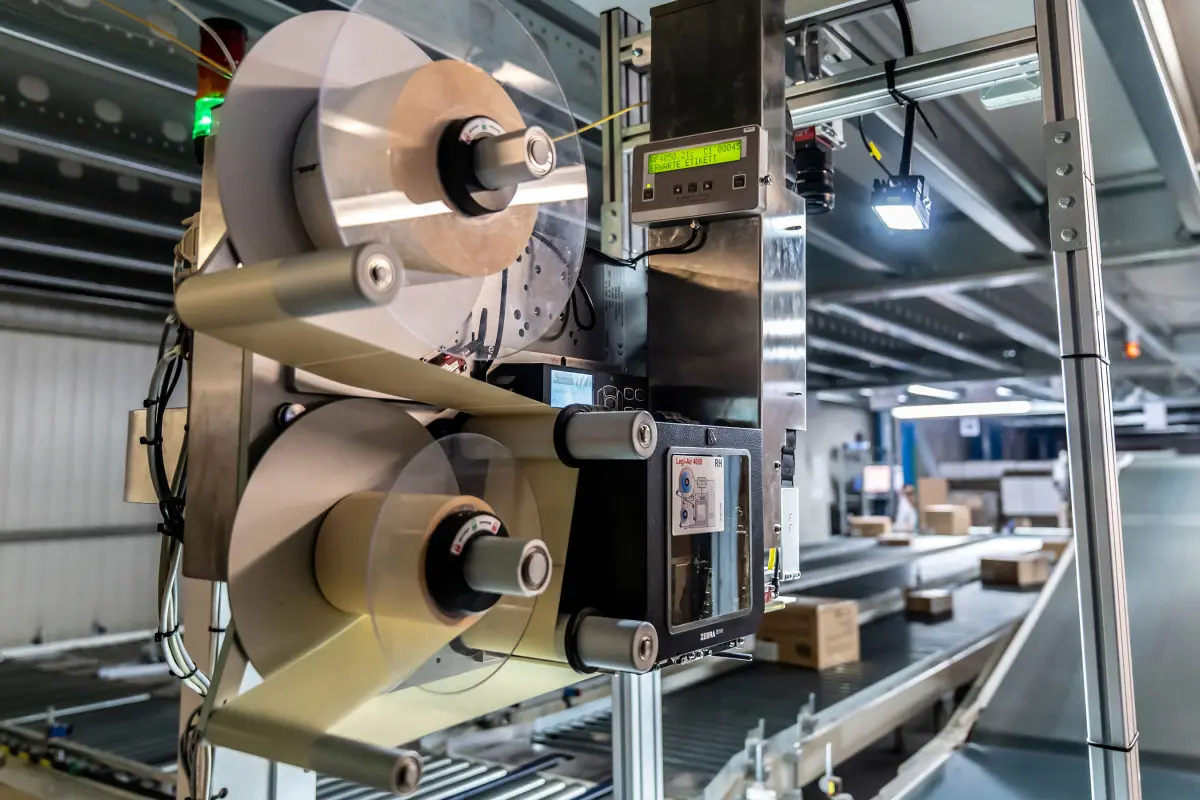

Labelling: Labelling medical products and outer packaging

In addition to direct labelling systems, print-apply-systems can also be used at all packaging levels - primary, secondary and tertiary. They print all the necessary information fully automatically on a label and apply it to the product or packaging. The Legi-Air series labellers from Weber Marking Systems offer a range of different dispensing stamps to apply the labels to the product.

Instead of a normal label, the products can also be labelled with RFID labels in the form of Smart Labels. With smart labels, a printing system prints the content onto the label. In addition, the integrated RFID chip is programmed and labelled. RFID is a particularly interesting technology when information needs to be read at a distance or in bulk. In addition, more information, e.g. in other languages, can be accommodated here than with a normal label.

The Legi-Air 4050 is an RFID labelling system that prints and applies RFID labels fully automatically. The integrated RFID printing module prints and programmes smart labels with all the necessary information. A bad tag reject is also available for the system. It automatically sorts out any faulty or unreadable RFID labels.

What role does GS1 play in UDI implementation?

GS1 is a company that develops identification, communication and process standards and promotes their implementation. Accordingly, GS1 is also involved with the Medical Devices Act and its implementation. GS1 Germany is accredited by the EU Commission as a UDI allocation centre: Manufacturers of medical devices and in-vitro diagnostics that implement UDI with GS1 standards therefore not only fulfil the labelling and identification requirements for the USA, but also those for the EU.

GS1 as a UDI allocation centre - what does this mean in concrete terms?

Identification

The MDR provides three essential building blocks for the unique identifiability of medical devices and in vitro diagnostics:

- UDI Device Identifier (UDI-DI)

- UDI Production Identifier (UDI-PI)

- Basic UDI (UDI-DI)

GS1 provides standards that enable UDI-compliant identification of medical devices and in vitro diagnostics. These are

- the Global Trade Item Number (GTIN). It can be used as a UDI ID.

- the GS1 data identifier. It can be used as a UDI-PI.

- the Global Model Number (GMN). It can be used as a basic UDI-DI. As part of the GS1 standards, the GMN is used to identify the model of a product from which the trading unit is derived.

Labelling

For machine-readable labelling - UDI stipulates that all information on the UDI-DI and UDI-PI must be attached to the packaging or the product itself - GS1 also offers solutions with various GS1 barcodes.

- GS1-128 barcode (linear barcode or barcode)

- GS1 DataMatrix (two-dimensional code)

- RFID (in addition to the barcodes)

Data exchange

According to the UDI, manufacturers must also transmit the master data of the products to the European UDI database. GS1 recommends that manufacturers make the data available to all users via the global data exchange network GDSN.

Practical implementation of UDI with GS1 standards

GS1 has set up a GS1 Solution Partner platform specifically for the practical implementation of GS1 standards and process recommendations. This brings together companies from a wide range of sectors. The GS1 Solution Partners advise medical technology companies and manufacturers of in-vitro diagnostics on the implementation of UDI in accordance with GS1 standards and offer suitable solutions.

Weber Marking Systems GmbH is a GS1 Solution Partner for the labelling of medical devices and in-vitro diagnostics. The company is a full-service provider of labelling solutions - from laser marking and inkjet printers to labelling systems. The labelling expert knows the requirements of the Medical Device Regulation and is very familiar with the GS1 standards. Weber Marking Systems has tested various labelling processes on materials such as paper, film and metal and knows which system solution is suitable for the various medical devices and their packaging. This is because the labelling must be as durable and abrasion-resistant as possible - even permanent in the case of surgical instruments and implants - and very easy to read.

What are the next steps for manufacturers of medical technology and in-vitro diagnostics?

As a manufacturer of medical devices or in-vitro diagnostics, you should first check which deadlines apply to the implementation of UDI for your products. Institutions such as GS1 will support and advise you on how to identify and label your products in a UDI-compliant manner.

Even if longer transition periods still apply to your products, you should already take care of the implementation of UDI now. This is because the capacities of individual solution providers are limited. In addition, production facilities may need to be adapted - especially if new marking technology needs to be integrated. This requires timely planning so that you can launch your products on the market in a UDI-compliant manner on time.

As a GS1 Solution Provider, Weber Marking Systems will be happy to advise you free of charge and without obligation on how best to label your products in a UDI-compliant manner.