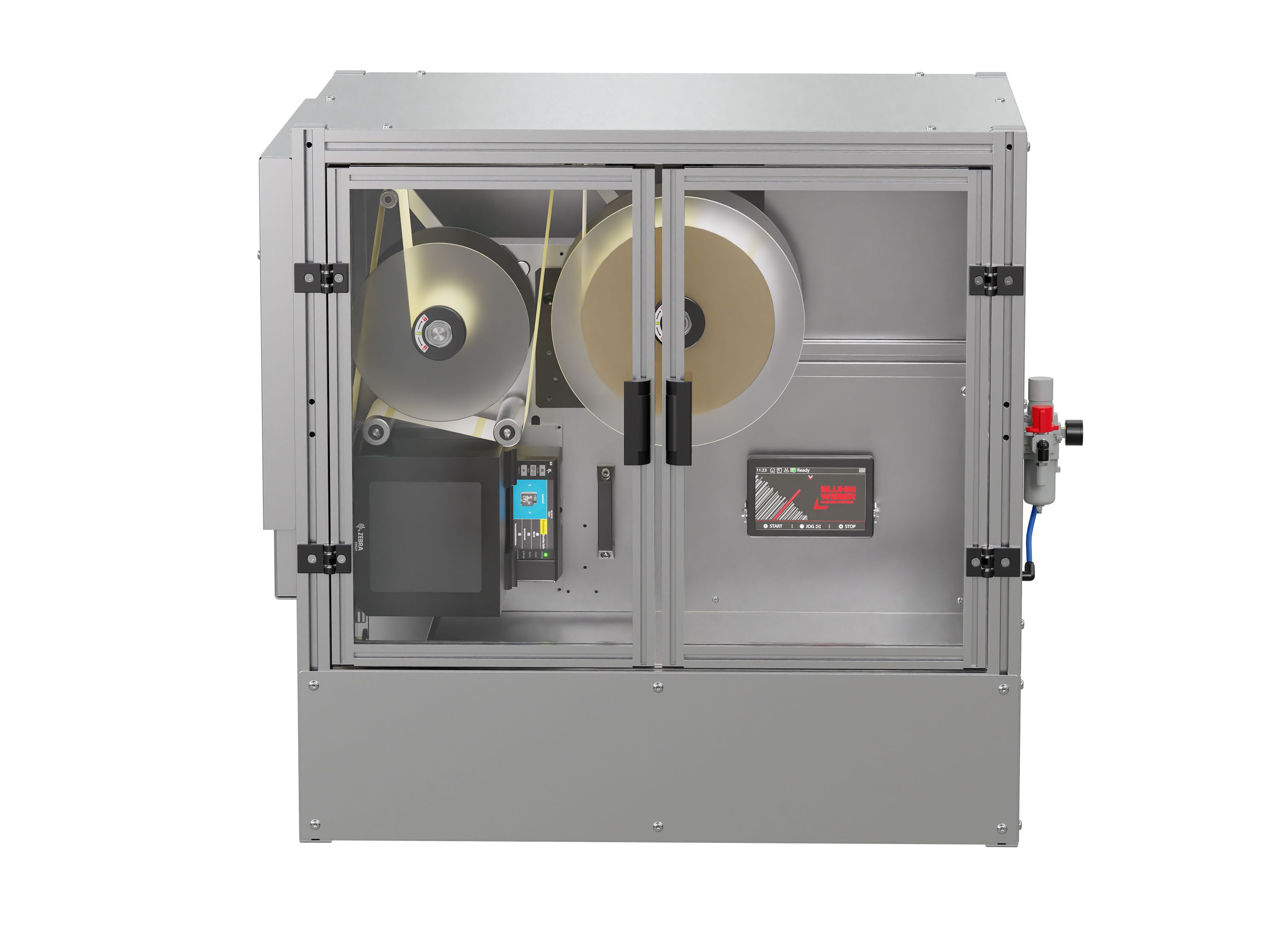

Intrinsically safe, very compact 3-sided labeler

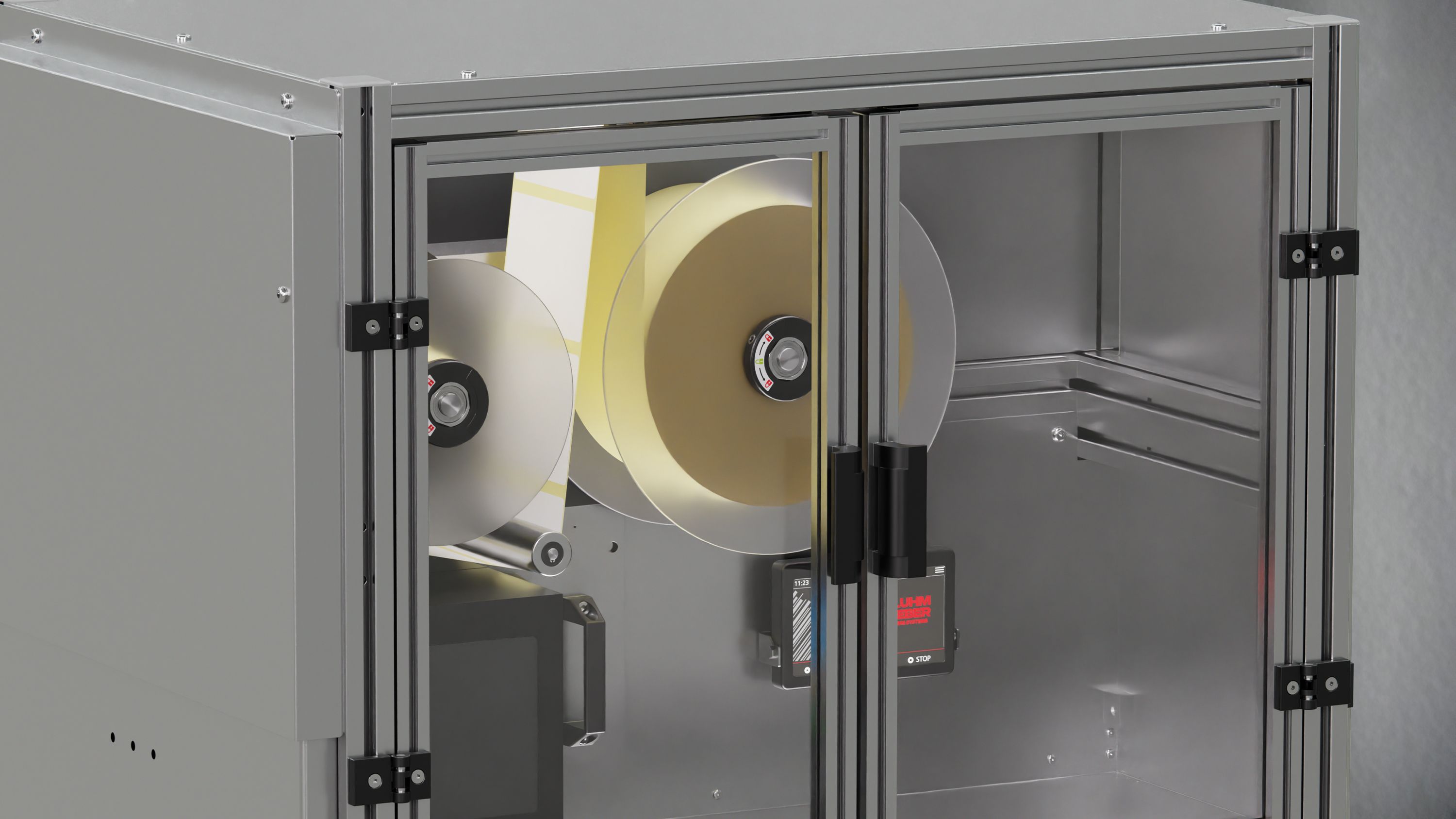

The Legi-Air AP182 pallet labeler creates and processes GS1-compliant labels in DIN A5 or DIN A6 format; other label sizes are optionally available. The labeling material can be applied to pallets ready for dispatch in portrait or landscape format. For example, portrait-format transport labels or landscape-format labels with content information can be processed. The use of label rolls with a diameter of 350 millimetres ensures an efficient and long production time. The AP 182 achieves high speeds of 120 pallets per hour for two-sided labeling and 90 pallets per hour for three-sided labeling.

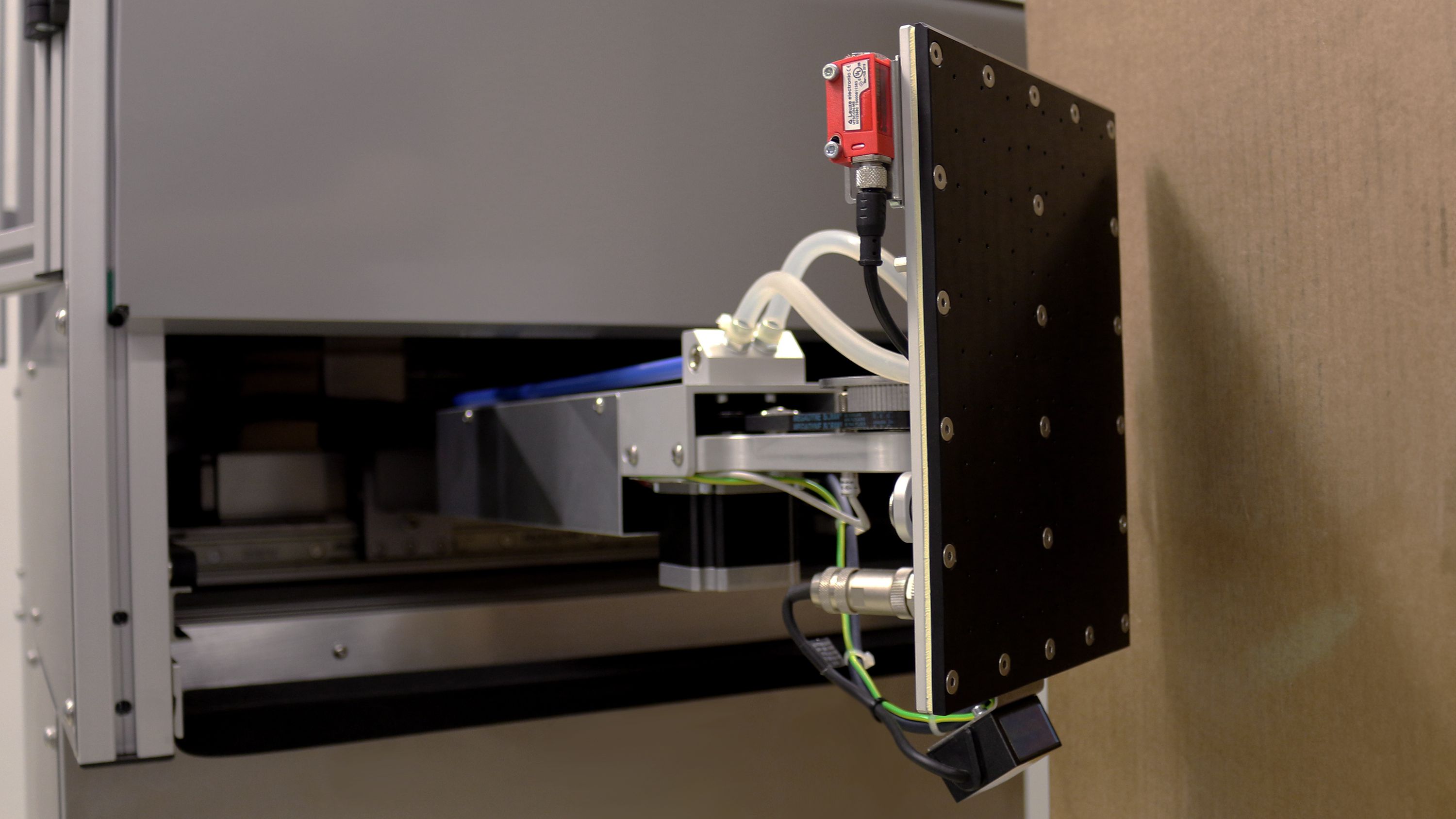

The labels are printed by an integrated print module. A wide selection of high-quality print modules from renowned manufacturers is available for configuration, achieving print resolutions of up to 600 dpi. As it does not require a safety fence thanks to its intrinsically safe design, the system saves costs and effort in logistics.