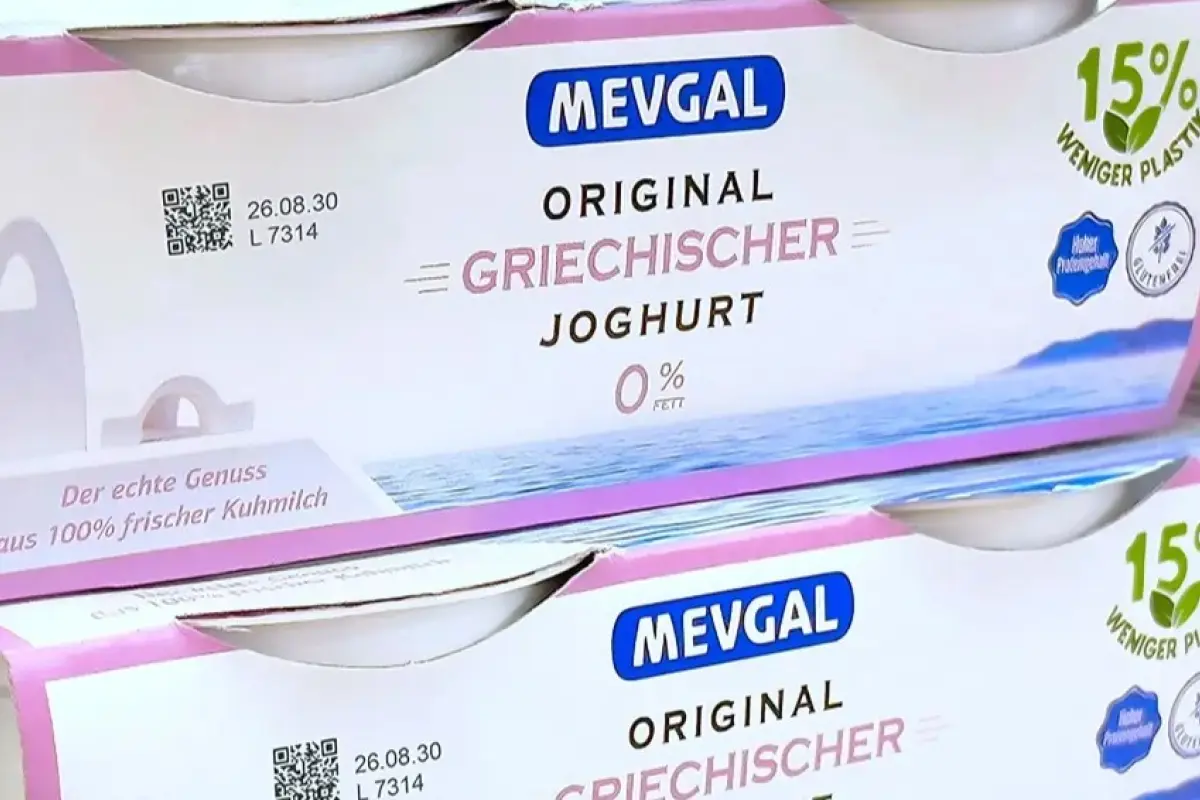

The switch to 2D codes poses a challenge in terms of production technology. While static EAN codes are usually pre-printed on packaging, 2D codes require dynamic coding during the production process.

1. Resolution and readability of 2D codes

2D codes require a significantly higher resolution than linear barcodes so that the data they contain can be read. If the resolution is too low, readability is reduced and the error rate during data capture increases. In addition, material properties and special features of the production environment, such as extreme temperatures, dust exposure or humidity, can severely impair the print image.

Choosing the right marking technology is crucial here. Our systems deliver reliable results even under harsh industrial conditions.

2. Marking speed of 2D codes

In many industries, the speed of product marking is essential. On particularly fast production lines, it can be challenging to achieve sufficiently high resolution for 2D coding without slowing down production.

Our high-performance systems are specially designed for such requirements and guarantee precise coding at high speeds.

3. Integration into existing systems

The switch to 2D marking solutions requires careful planning and smooth integration. Companies must check whether their existing printers and systems meet the new requirements or need to be replaced.

Thanks to their modular design, our marking solutions can be flexibly integrated into existing systems with little effort and easily expanded as required.