HP Europe partners with global transport business Kuehne+Nagel to handle HP Instant Ink packaging and logistics. HP Instant Ink is an ink subscription service that automatically delivers ink or toner only when you’re running low. A Markoprint inkjet printer from Weber Marking Systems features HP thermal ink jet (TIJ) technology, applying HP 2510 pigment-based ink for brown boxes and HP 2590 solvent ink for clay-coated boxes.

The solution replaced labels with fast, high-resolution, high-quality, low-maintenance direct printing solution that also improved sustainability. Outstanding results for complex requirements such as those at Kuehne+Nagel can be achieved in the shortest possible time thanks to the long-standing excellent partnership between Markoprint and HP.

Challenge:

Replace adhesive labels with direct coding on shipping boxes

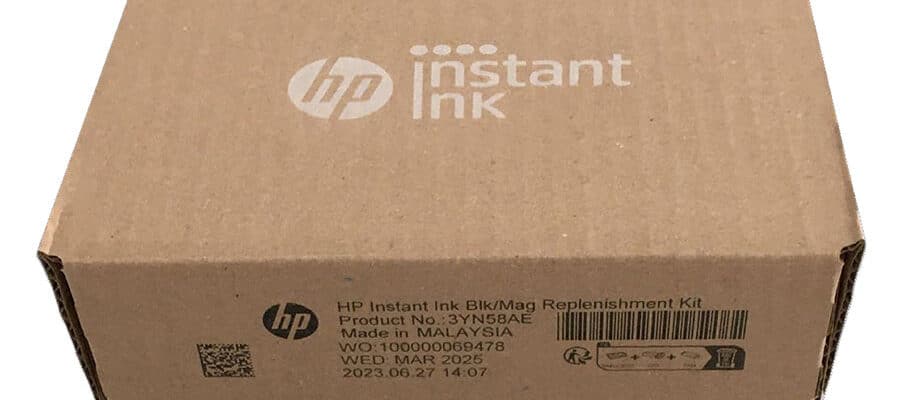

Kuehne+Nagel wanted to replace its label printer with direct printing of required coding and marking information onto HP Instant Ink boxes. Traditional printing and the application of labels added costs due to downtime, stock management and waste of expired label stocks to the packaging process. The company was looking for an alternative direct printing solution for coding and marking that could be seamlessly integrated into its production line, and deliver high-speed, high-quality, crystal-clear 2D barcodes for both the human eye and barcode reader.

Solution:

Markoprint inkjet printer with HP ink cartridges

Kuehne+Nagel worked closely with HP Specialty Printing and Technology Solutions (SPTS) division TIJ licensee, Weber Marking Systems and HP Operations team to integrate its Markoprint X4JET printing system into its production line. Kuehne+Nagel tested different inks and selected HP 2510 pigment-based ink and HP 2590 solvent ink as ideal for printing on HP Instant Ink boxes.

Outcomes:

Increased efficiency and sustainability

The winning combination of Markoprint coding equipment and HP TIJ technology at Kuehne+Nagel has:

- Eliminated the need for costly adhesive labels.

- Increased sustainability and recyclability.

- Reduced the coding and marking costs of label and ribbons, order management and expired label waste.

- Increased production efficiency – up to 72 prints per minute – with lower maintenance costs and downtime while delivering consistently high print quality, including higher resolution 2D code printing.

- A new coding layout which is easier to read and scan, further improving workflow efficiency, and enabling the company to look at late-stage customization opportunities.

Markoprint is the only manufacturer in the world that can centrally control five different printing technologies, including the innovative ink cartridges from HP! The thermal inkjet coding method is suitable for almost any product and packaging. The patented Click’n’Print cartridge holder also makes ink changes particularly quick and easy.

Your benefits with Markoprint and HP:

✅ Low running costs

✅ High speed printing

✅ Consistent print quality

✅ Up to 600 dpi print resolution

✅ … and many more!