The terms rubber and elastomers are often used interchangeably, and the term rubber is used colloquially. In the narrower sense, however, elastomers are synthetically produced, whereas rubber is made from natural raw materials. Vulcanisation (curing) makes (synthetic) rubber dimensionally stable. Depending on the degree of vulcanisation, a distinction is made between elastomers (soft rubbers) and thermosets (hard rubbers). Products and components made from elastomers include:

- Drive elements such as belts and tapes

- Car tyres

- Insulating, sealing and connecting elements

- Individual moulded rubber parts

- Rubber mats and sheets

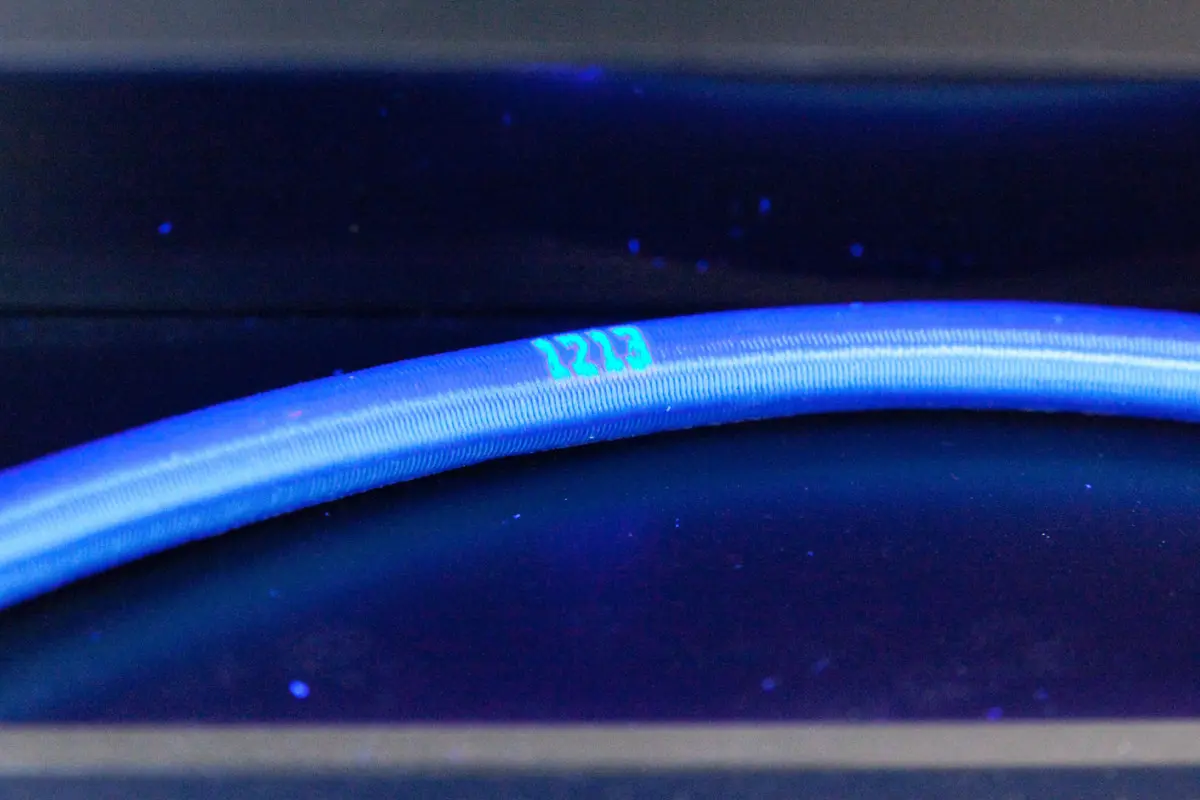

- Profiles, cables, rings and hoses

The most important synthetic rubbers are SBR (styrene-butadiene rubber) and EPDM (ethylene-propylene-diene rubber).