How labeling machines work

Labeling machines apply pre-punched labels to products and containers - much faster and more precisely than would be possible by hand alone.

They therefore make an important contribution to automation in industrial production. Depending on requirements and production volumes, manual, semi-automatic or fully automatic systems are used. Depending on the application, cold glue, hot melt, wet glue or self-adhesive labeling machines are used.

Labeling systems differ in terms of whether they only apply finished labels (label dispensers or application systems) or can also print themselves thanks to their own print module (print and apply systems). The latter are useful, among other things, if individual data from ongoing production or from a database is to appear on the labels. This could be serial numbers from an ERP system or codes from inspection software, for example. Alternatively, such information can also be applied later in the production process using inkjet printers or laser markers.

Our labeling systems

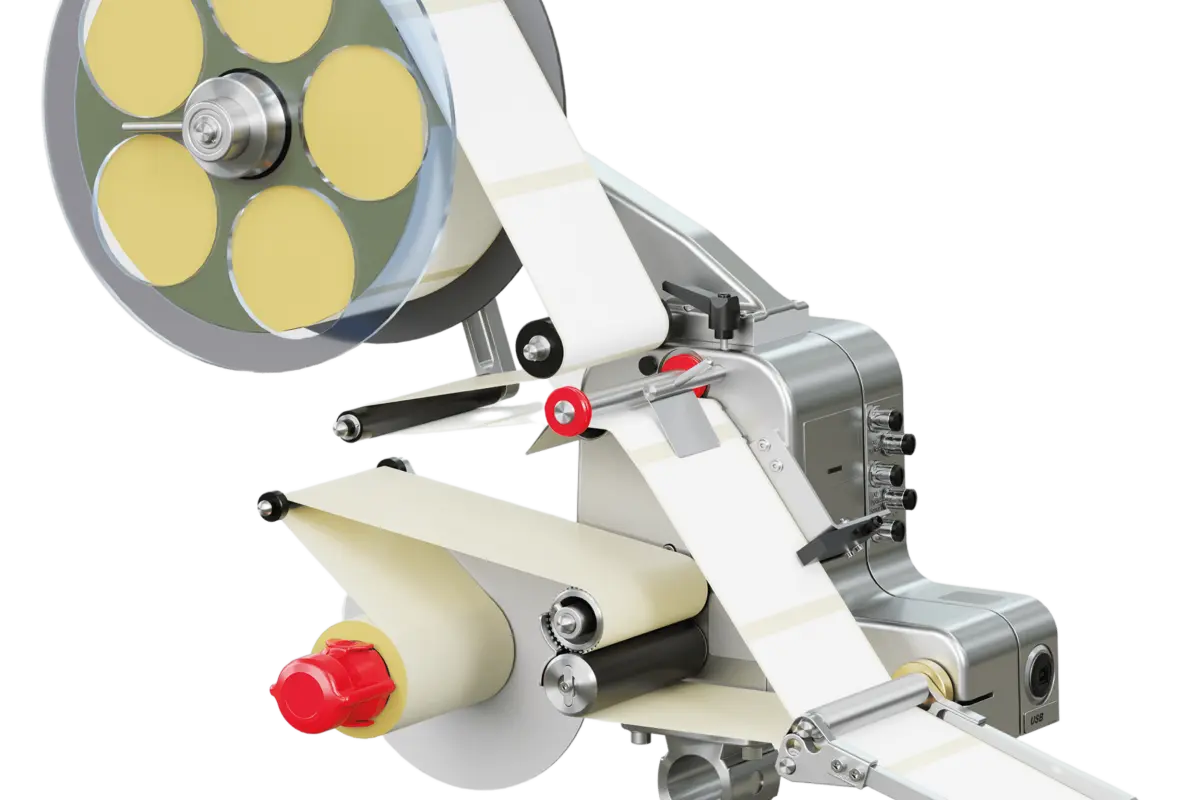

Automatic labelers

Automatic labelers apply pre-printed labels quickly and accurately to products or packaging.

The various applicators enable almost any application in industry and logistics. They are designed for continuous operation 24/7. Our unique modular concept enables our customers to customise each system to their individual requirements. We place the highest value on robust, powerful and economical solutions.

Automatic labeler with integrated printer

Automatic labelers with an integrated print module are called Print-Apply-Systems.

These can add customised information to the labels during the application process. This can include, for example, best-before dates, dispatch information, serial numbers, barcodes and graphics. This data can be transferred from a connected database or software and can vary during production.

Labeling machines with conveyor technology

Labeling machines are labeling systems that are equipped with an integrated conveyor belt and special modules for product handling.

They can label various forms of packaging efficiently and precisely by automatically aligning, rotating, wrapping or otherwise handling the product according to individual specifications. They are suitable both as stand-alone complete systems and for integration into higher-level production and dispatch processes. Weber Marking Systems offers labeling systems in various levels of automation. Our portfolio covers classic standard applications and our experience enables customised special solutions at any time.

Pallet labelers

Pallet labelers identify large packaging units in the form of containers or pallets by automatically applying shipping labels to them.

A built-in print module provides the label with individual logistics information such as the SSCC number to enable fast and clear identification of the pallet along the entire transport route. Our pallet labelers can apply up to three GS1-compliant labels to different sides of the pallet in just one work step.

RFID labelers

RFID labelers can automatically code, print and apply radio labels for products, packaging and transport units.

The labels contain a so-called RFID transponder: a microchip with an antenna on which data can be stored, changed and deleted . A suitable reader can read several RFID labels simultaneously without visual contact. By the way: Many label print and apply systems from Weber Marking Systems can be easily configured as RFID labelers.

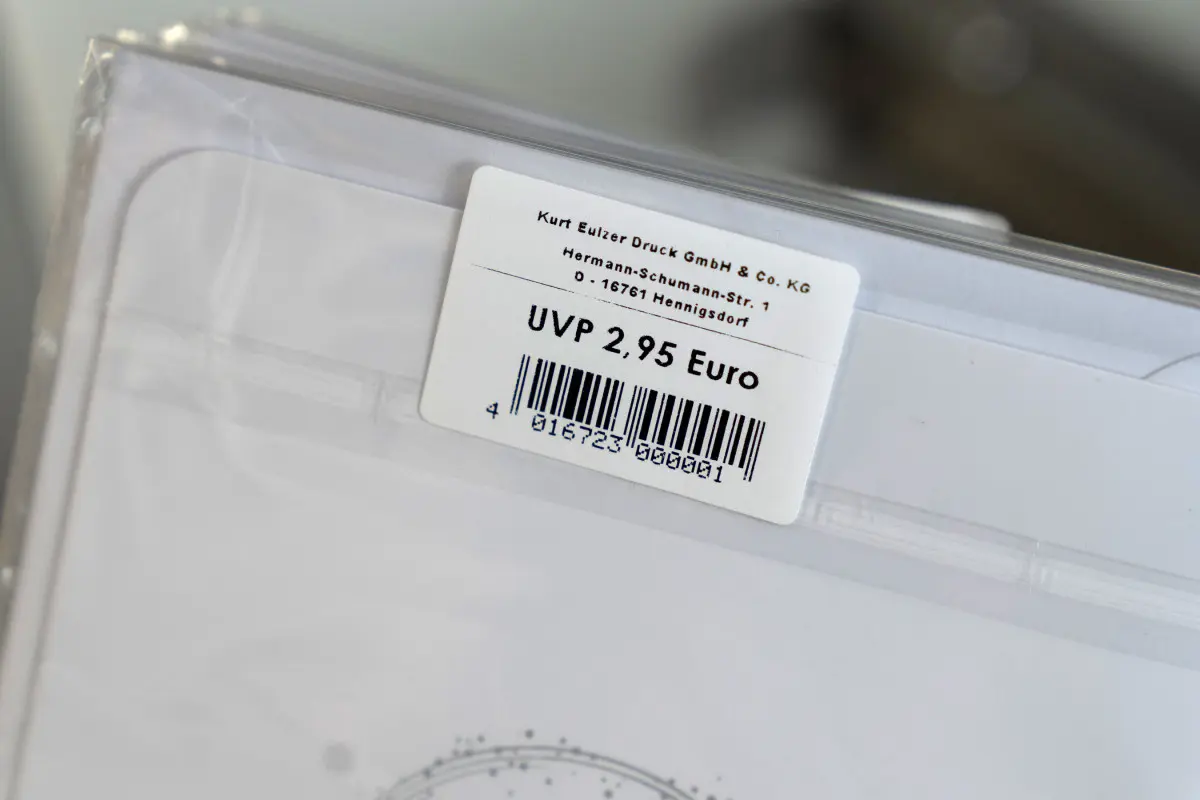

Label printer

Label printers create self-adhesive labels (e.g. barcode labels) with customised information and have functions and features that go beyond conventional home or office printers.

Whether printing in black and white or colour, they are designed for large print volumes and high print speeds as well as for different label formats and materials. In addition, their housings are robustly built for harsh production environments. They have interfaces that transfer variable information (e.g. batch numbers) from databases and print it on the label. The integrated print modules from the world's leading manufacturers can also be found in our label print and apply systemes.

Areas of application for labeling systems

Labeling is a widely used technology in modern marking technology. It enables precise, flexible and economical labeling of a wide variety of materials. Manufacturers from a wide range of industries use this technology for labeling products and their packaging; here is a small selection of common areas of application:

Beverages and food

Product labels on food packaging and beverages, pallet labeling, labels for outer packaging and trays.

Logistics and e-commerce

Shipping labels on boxes and shipping bags, pallet base labeling for internal logistics, pallet labeling in logistics.

Pharmaceuticals and cosmetics

Wrap-around labeling of medical or cosmetic containers, serialisation with sealing labels.

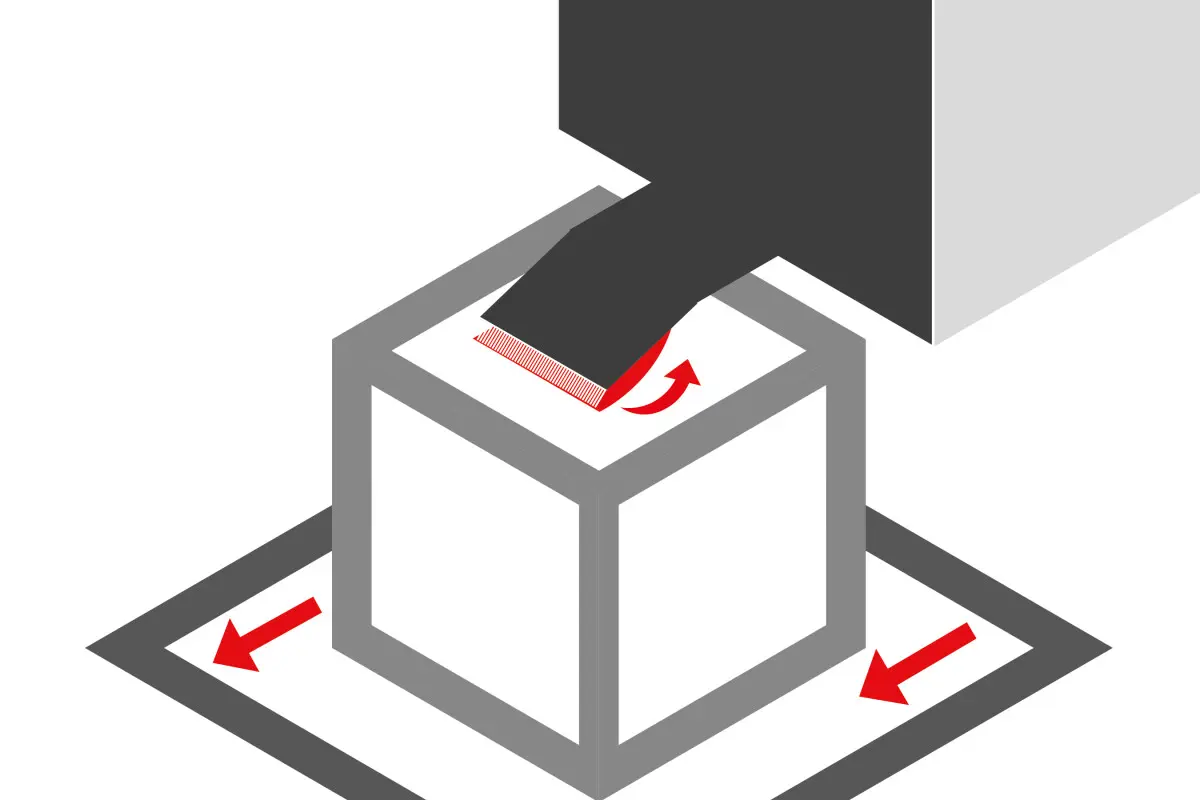

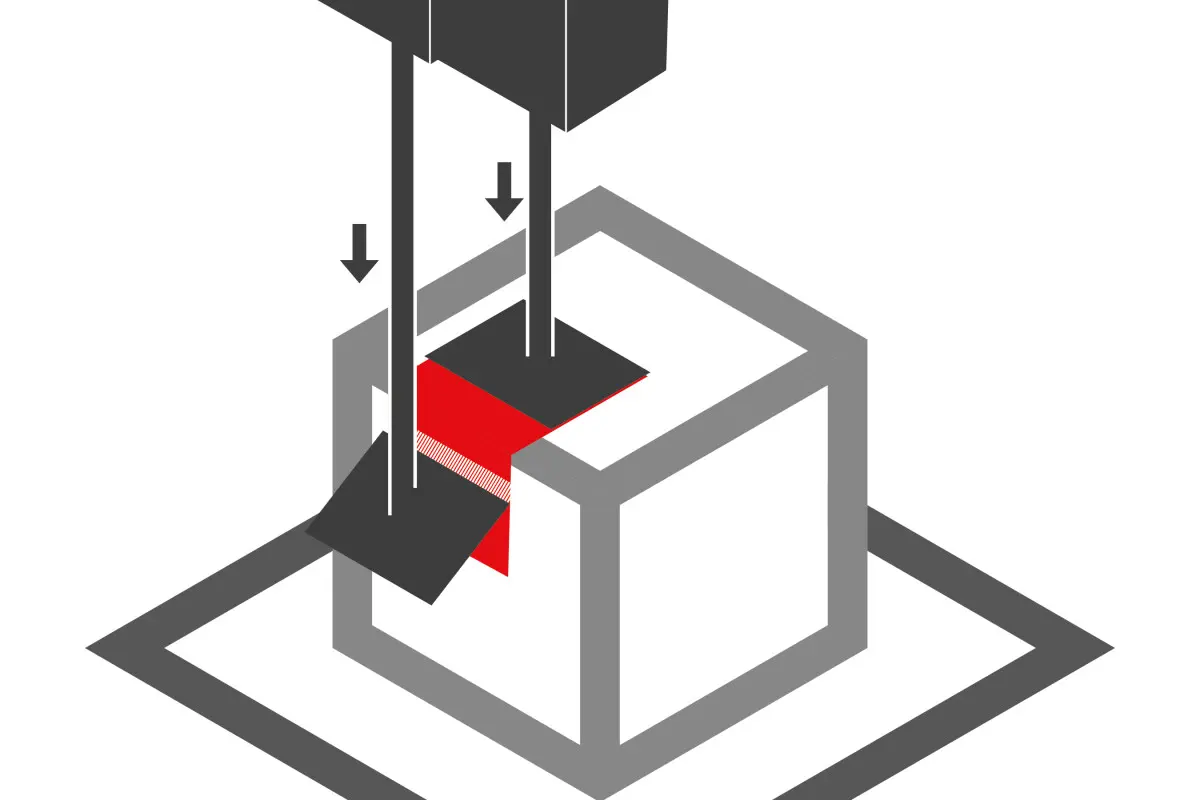

Automatic label application methods

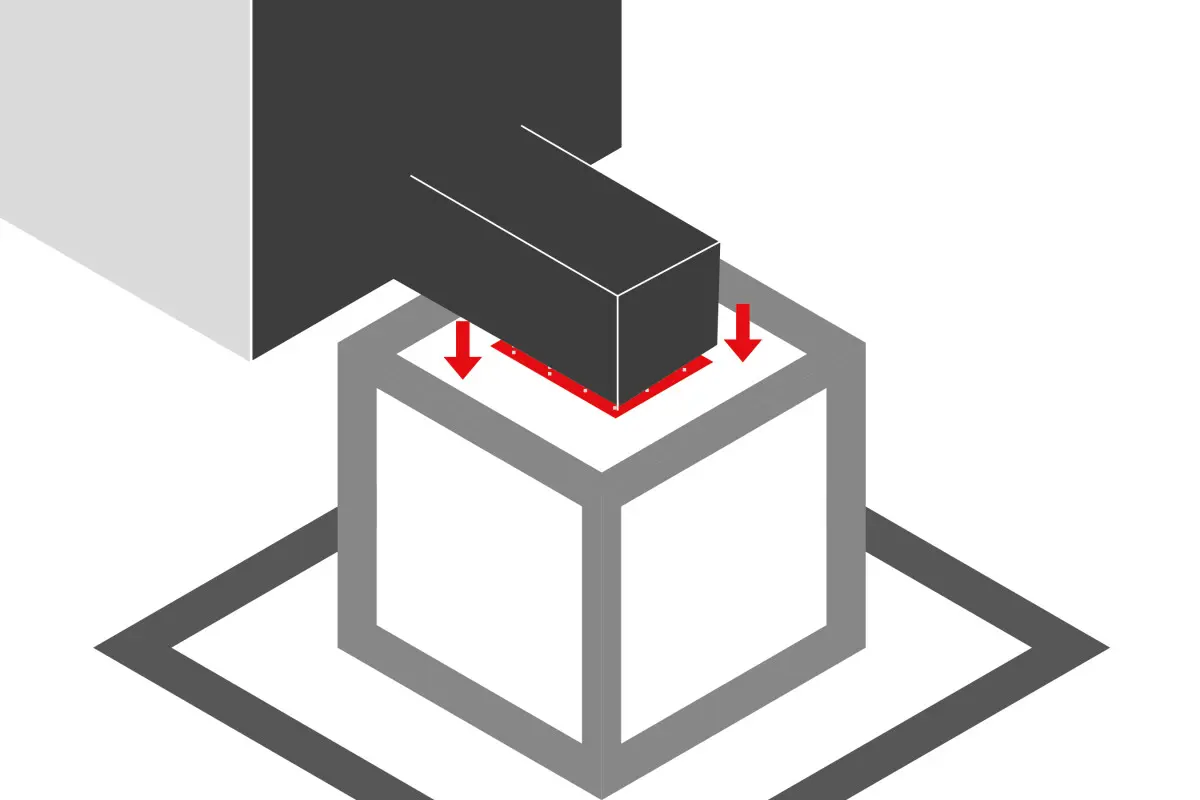

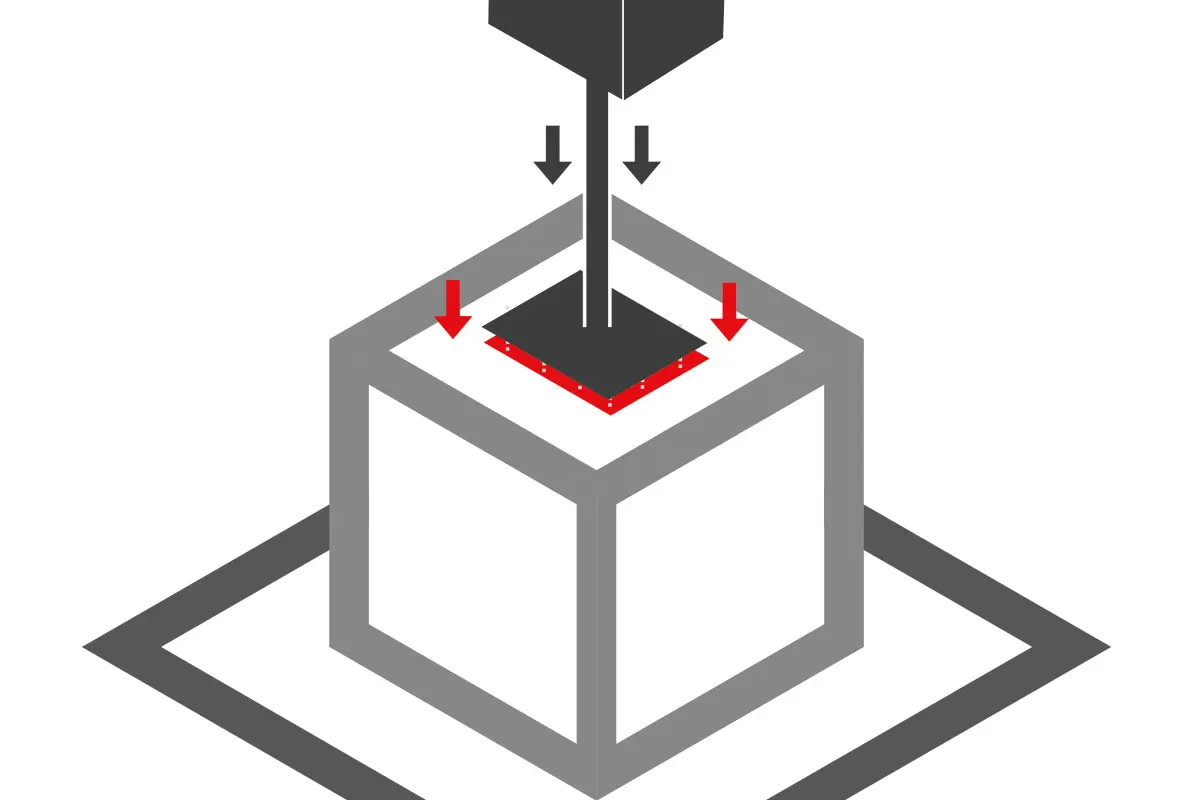

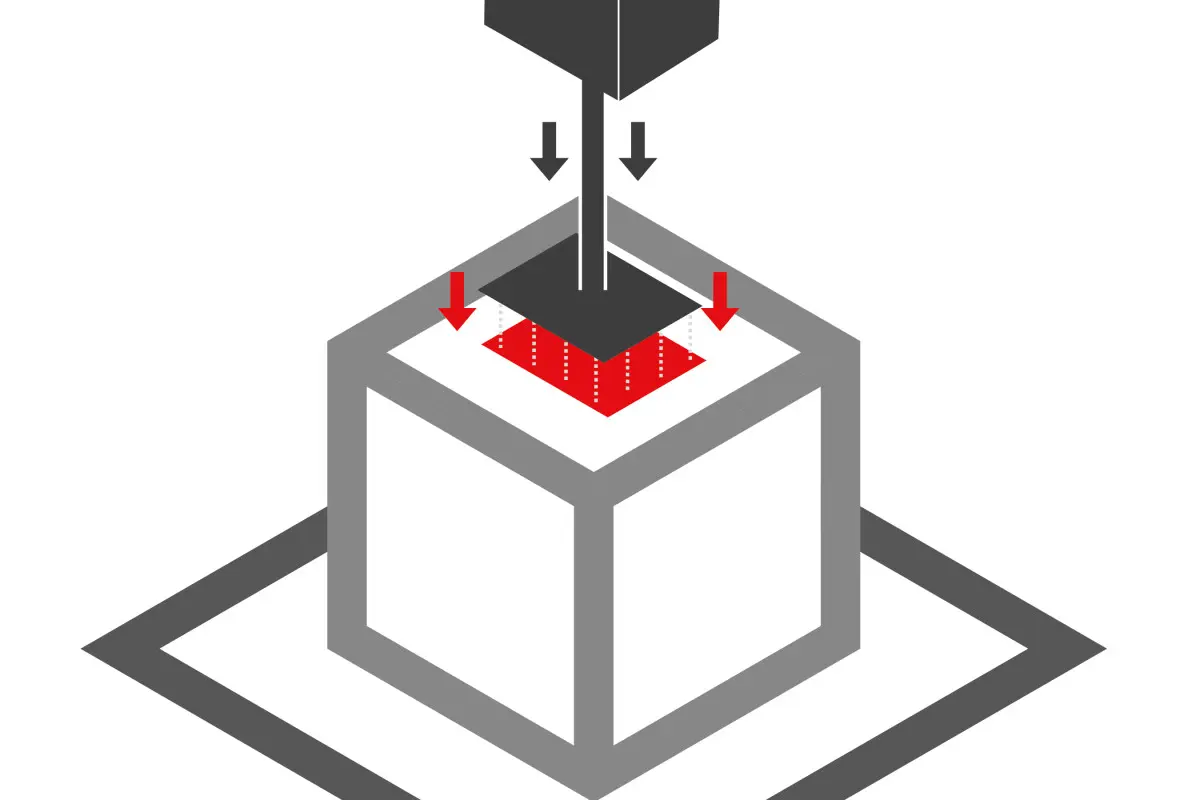

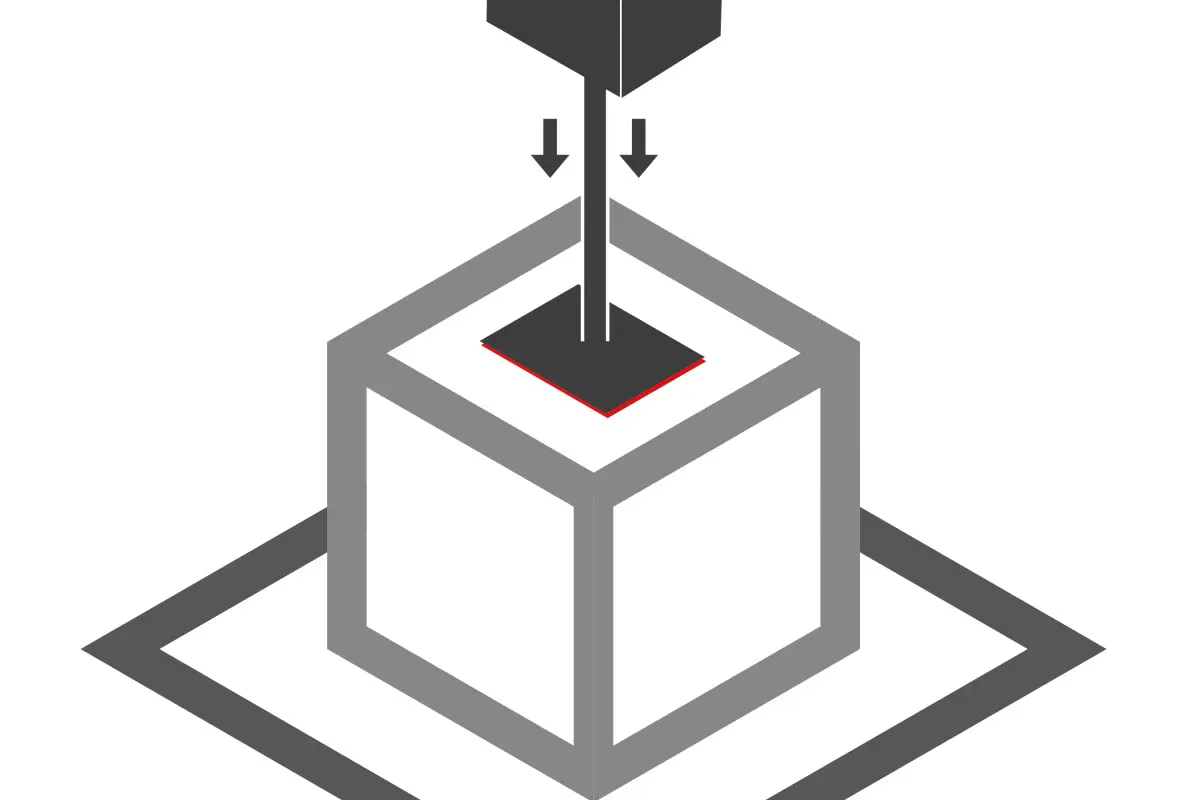

The applicators of labeling devices transport labels from the roll or the print module to the product and are responsible for applying the label to the product surface. The choice of applicator depends on the labeling process. A basic distinction is made here between labeling with or without contact. Touch labeling offers the advantages of greater precision and speed, while non-contact labeling is particularly gentle.

Advantages of automatic labeling systems

- Modular design: Labeling systems for industry should consist of different modules such as applicators, tamps and print units so that they can be flexibly combined, supplemented and exchanged. As a labeling expert, Weber Marking Systems has a highly developed and standardised modular construction system. This high level of flexibility results in short planning and delivery times.

- Minimise errors thanks to automation: Labeling systems apply labels automatically, which is much faster than applying them manually. They place the labels precisely in the required position and minimise mislabeling.

- Durable: Industrial labelers are durable, extremely robust and designed for 24/7 operation in industrial environments.

- Labeling in throughfeed or at a stop: Labeling can take place in throughfeed, i.e. while the product is moving past the labeler on a conveyor belt, for example, or at a stop if throughfeed is not possible or not desired.

- Versatile: Labeling technology is as diverse as its possible applications. They process labels of all types and formats.

Alternatives to labeling

Have you ever considered alternative technologies? At Weber Marking Systems, you can find them all from a single source!

Your personal contact from our sales team will discuss possible alternative technologies with you and find the most economical and productive solution for your labeling task. If the task is particularly complex, the various technologies can of course also be combined with each other. The compact and modular design of our labeling devices makes this possible.

Inkjet printing

Inkjet technology is a very suitable labeling alternative. One advantage is the direct and contactless labeling, which means that no labels are required. This saves costs, reduces waste and enables labeling on a wide variety of surfaces, even on uneven or curved shapes where labels reach their limits. Special large character printers also cover print heights that are more difficult to realise with labels, depending on the application. The direct printers code from above, below or from the side and, with a large selection of inks, are suitable for almost any surface, especially those on which the adhesive strength of labels is limited.

Laser Marking

Lasered metal type plates or direct part marking with laser are good options for machines, components and tools. Laser marking is more robust than labels, especially if the marking is exposed to chemicals, heat or mechanical stress.

Industrial applications for automatic labeling

Labeling systems apply all conceivable label formats to any surface, which is why they can be found in every industry. Discover some practical application examples here.

Frequently asked questions about labeling

What levels of automation are available for labeling machines?

You can choose between the following labeling machines:

Manual labeling machine

Manual labeling machines are operated manually and are suitable for mobile labeling in smaller quantities. An example of this are price labeling machines.

Semi-automatic labeling machine

Semi-automatic labeling machines offer a higher degree of automation with less time and personnel expenditure. They are suitable for small to medium-sized batches or for seasonal goods, as the products have to be inserted into the labeling device by hand.

Fully automatic labeling machine

Fully automatic labeling machines are usually integrated directly into production and packaging lines, where they label products as they pass through. Using special modules, they can independently align, rotate or wrap the approaching containers, for example. Our Geset labeling systems are extremely flexible so that they can be ideally adapted to all local requirements.

Labeling machine for bottles

Whether disposable PET plastic bottles or reusable glass bottles: fully automatic and semi-automatic labeling systems with integrated print modules are available specifically for front and back labeling of wine, sparkling wine, juice and other beverages.

How does a labeling machine work?

First, labels on a roll are inserted into the labeling system. Depending on the application, these are already printed and only need to be applied. Otherwise, a print module is integrated into the labeling machine, which individually prints the labels directly before they are applied. The adhesive labels sit on a backing film, from which they are then removed via a peeling plate.

Semi-automatic and fully automatic labeling machines take over the application process automatically. Depending on the design of the system, the label must be supported by compressed air when it is peeled off the label roll so that it does not slip or wrinkle.

The label is then applied to the surface via a peeler plate or a movable applicator arm and, if necessary, additionally pressed on by a roller or brush. For very fast production speeds and sensitive surfaces, we recommend non-contact labeling, in which the label is blown off using compressed air. Applicator arm is that it can label products of different heights (e.g. cartons) one after the other. In order to hold the label under the tamp pad, it is sucked in via a generated vacuum. Instead of using compressed air, the applicator arm can also be driven electrically by a servo or stepper motor. Sometimes a combination of different applicators may be necessary, for example for over-corner labeling.

What labeling options are there?

Whether square, round, oval or conical shapes: Our labeling machines make almost any product suitable for labeling. This also includes flexible containers, cartons, sacks, packs, trays and pallets. We offer solutions for all sizes and surfaces - from glass, wood and plastic to paper and steel. We can also master the following challenges in the industry:

- Format changes

- From all sides

- GS1-compliant

- Critical surfaces

- Label security

- High speed

- Distance differences

- Freely selectable heights

- Precision

- RFID

- Tandem operation

- Long operating times

- Protective housing

- Alarm

- Cylindrical products

- Wrap-around labeling

Which factors may influence the positioning accuracy of labels?

The positioning accuracy of labels is influenced by factors on the labeling device and the product. The experts at Weber Marking Systems take these possible influences into account - the result is optimum, precise labeling.

1. The positioning accuracy on the labeler depends on various factors:

- Mechanical influences: Friction between the material and mechanical components of the labeler such as the tape brake, drive, peeler plate, deflection rollers and unwinding units.

- Influences of the label material to be processed: Surface quality and stretching of the material.

- Influences of the software: Switching frequency and hysteresis of the sensors used.

- Influences of the sensors used: The processing times/dead times and the parameters to be set.

2. The positioning accuracy on the product depends on various factors:

- Influences from the labeling device (see above).a

- Influences of the labeling material: The adhesive and the processing quality of the label (e.g. it may be punched or unevenly aligned on the backing material).

- Influences of the product to be labeled: Surface quality, shape and stability.

- Ambient conditions: Room temperature, humidity, draughts or turbulence that may occur due to nearby processes.

Your reliable partner

Weber Marking Systems is a leading full-service provider of industrial marking technologies. With a focus on innovation, quality and sustainability, we develop cutting-edge labeling and coding systems that meet the requirements of our customers in every industry sector. Our international sales network guarantees excellent world-wide support and service. No matter what challenges your application presents: We have the necessary experience to work with you to find the optimum solution.

- Your personal consultant will listen to you and explain the possibilities.

- We will develop the perfect solution for your application.

- Our international service network is always there to support you.

- You can rely on high-quality products made in Germany.

- Get all systems, consumables and services directly from a single source.