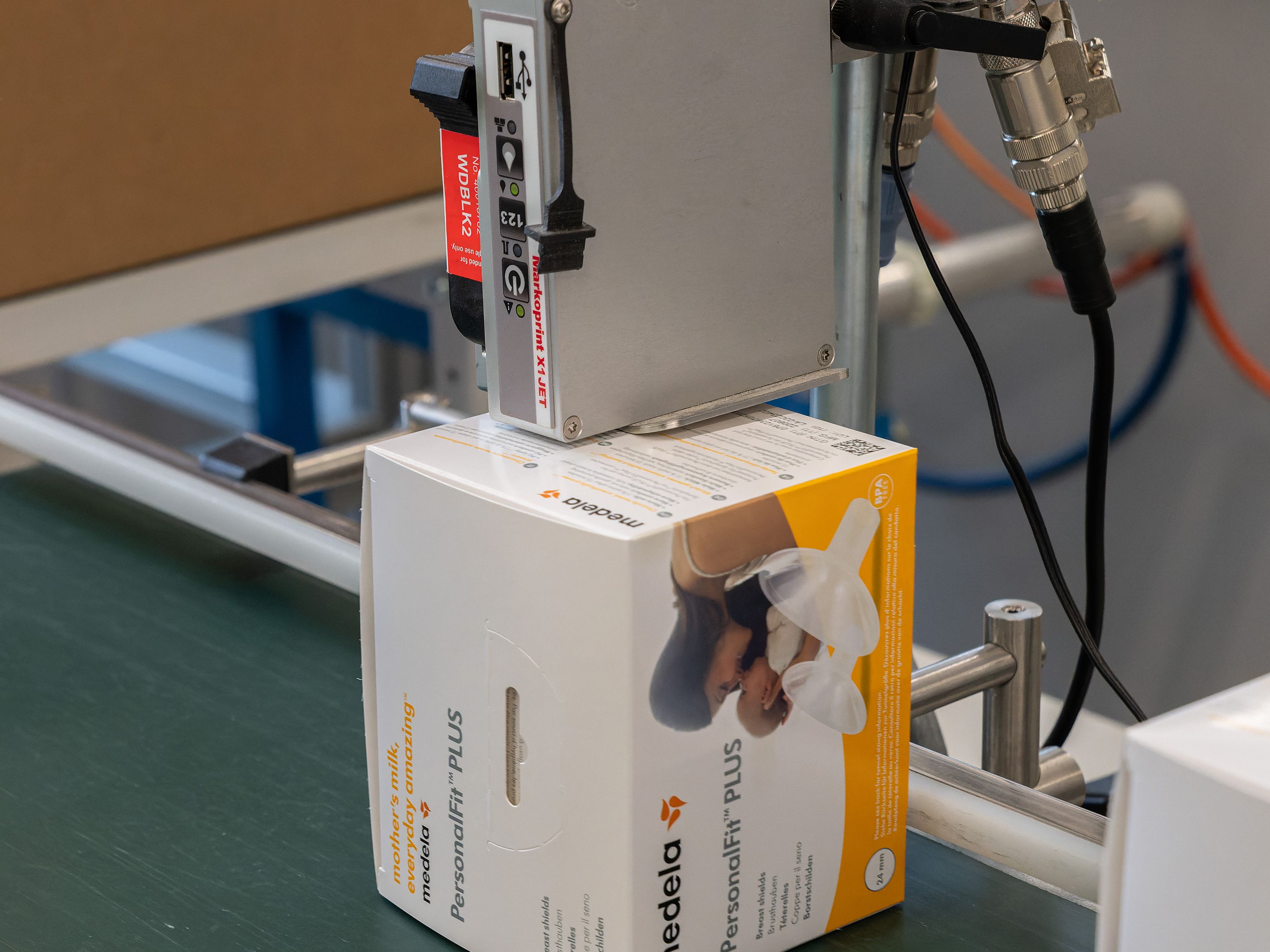

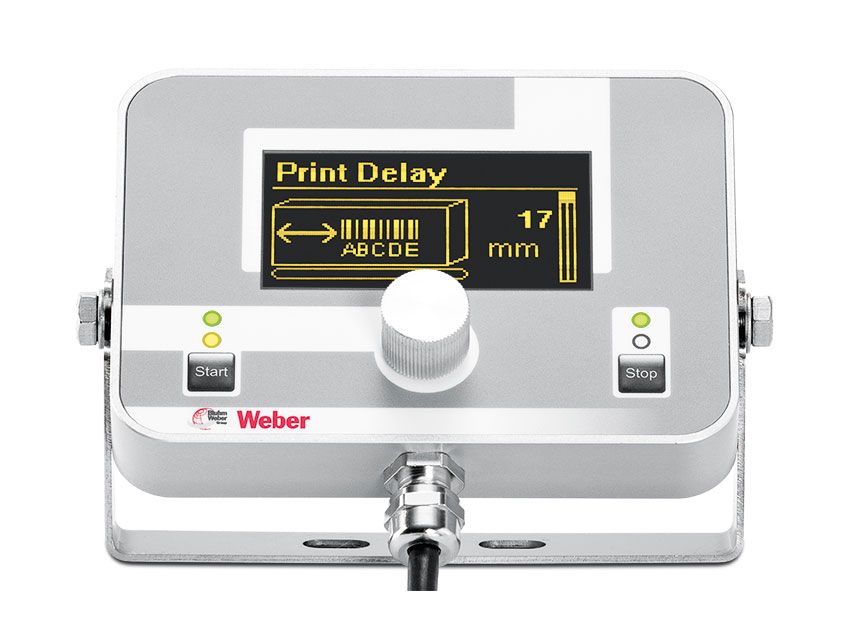

High-speed version: space-saving, affordable, flexible printing

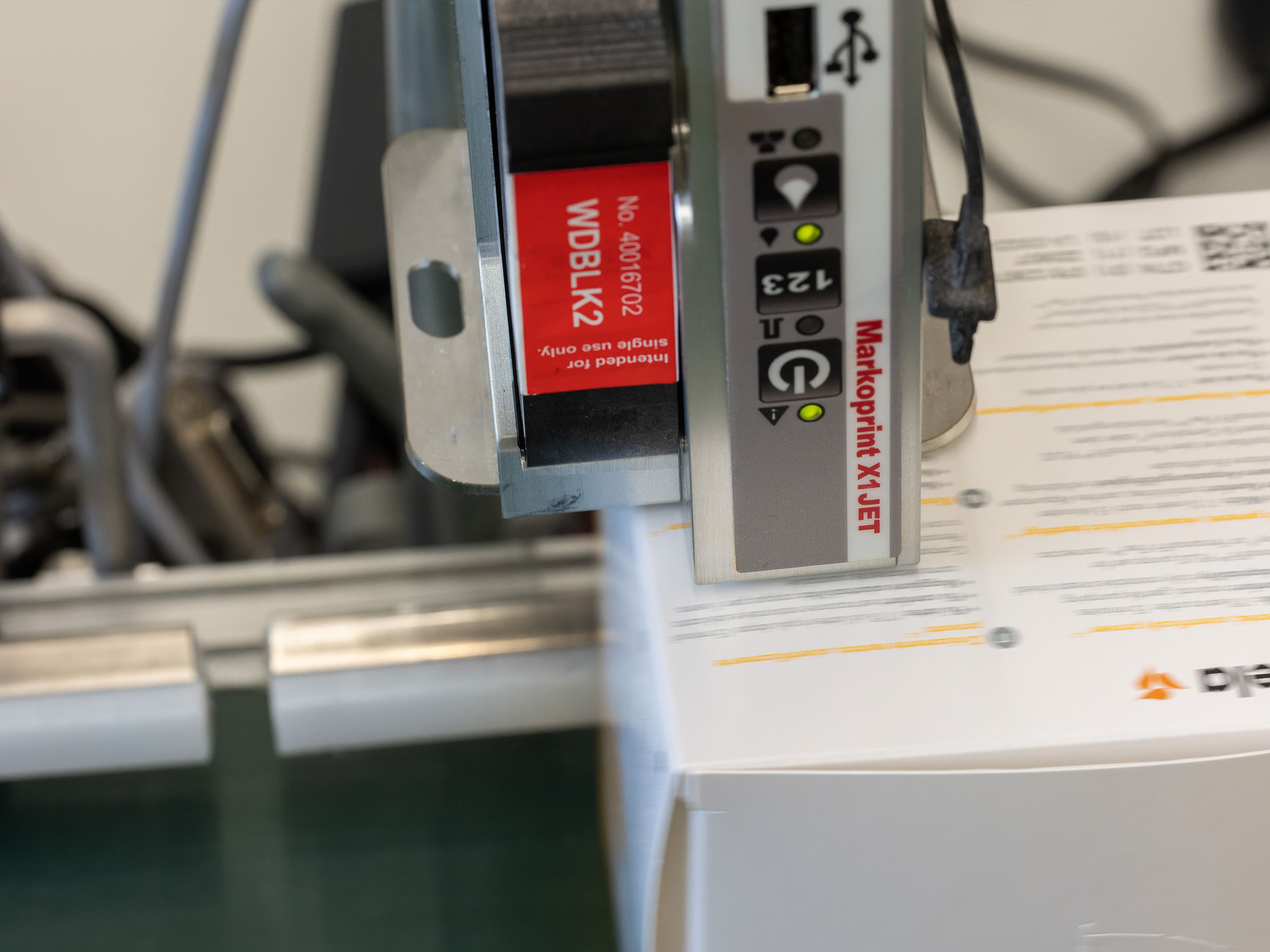

The Markoprint X1JET HP Premium labels flat absorbent and semi-absorbent surfaces precisely and reliably. The thermal inkjet printer with HP cartridge technology combines a printhead and controller in a robust enclosure made of anodised aluminium. This makes the printer extremely compact and therefore easy to integrate. The Markoprint X1JET HP Premium offers maximum planning freedom when space is limited, for integration into existing production systems or when developing new system concepts.

Compared to the standard version, it has an M8 connector as an additional power supply and prints twice as fast.

The printhead is also part of the ink cartridge. This means that the printhead is also replaced every time the cartridge is changed. This saves time-consuming maintenance and cleaning work and ensures optimum printing results. The Markoprint X1JET HP Premium prints text, 1D barcodes, 2D codes and graphics in high resolution and delivers brilliant print results on products and packaging. The labeling is smudge-proof, easy to read and durable and is suitable for the food, chemical, building materials and pharmaceutical industries, among others.