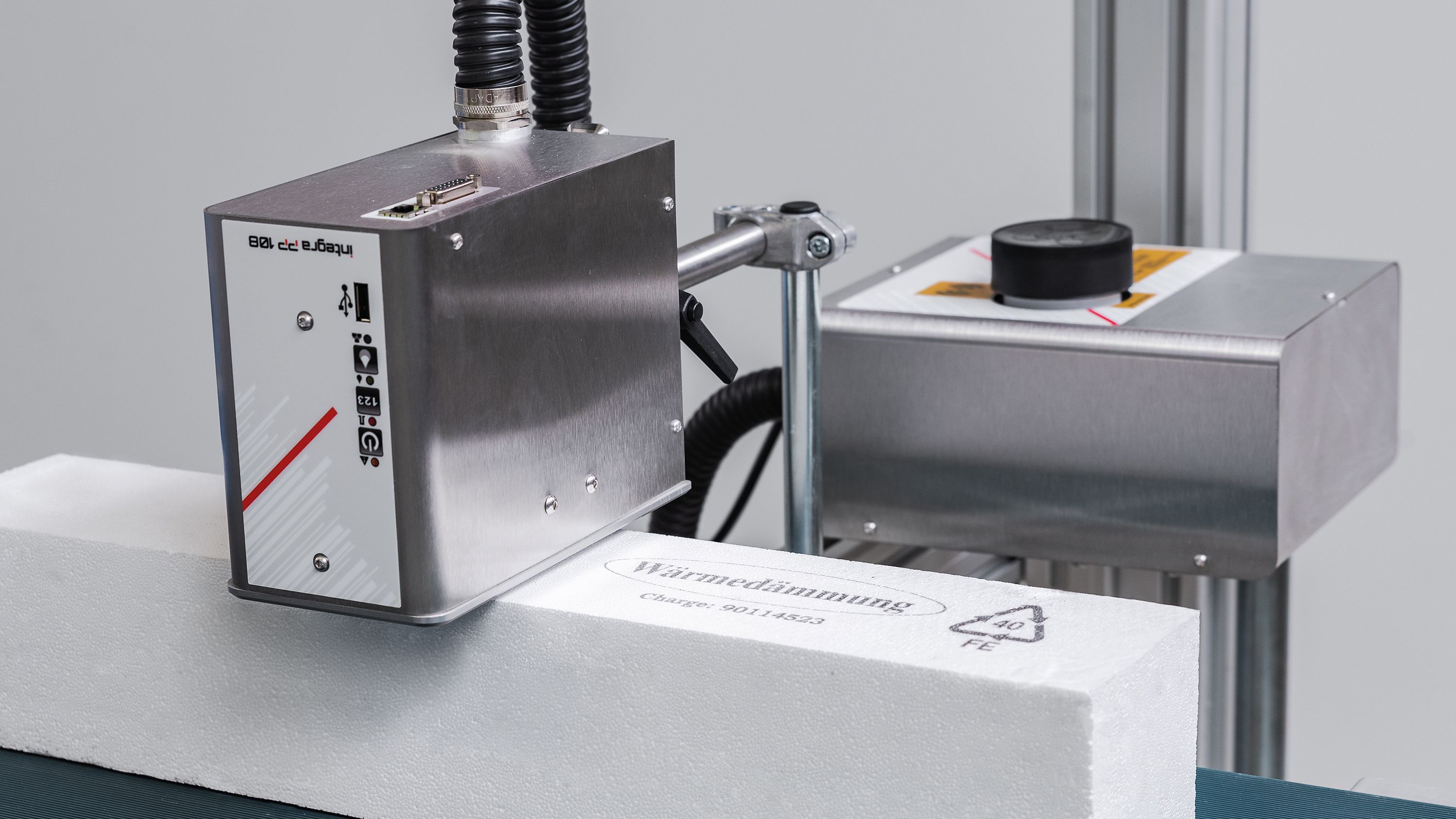

Robust large-character printer as an alternative to labels

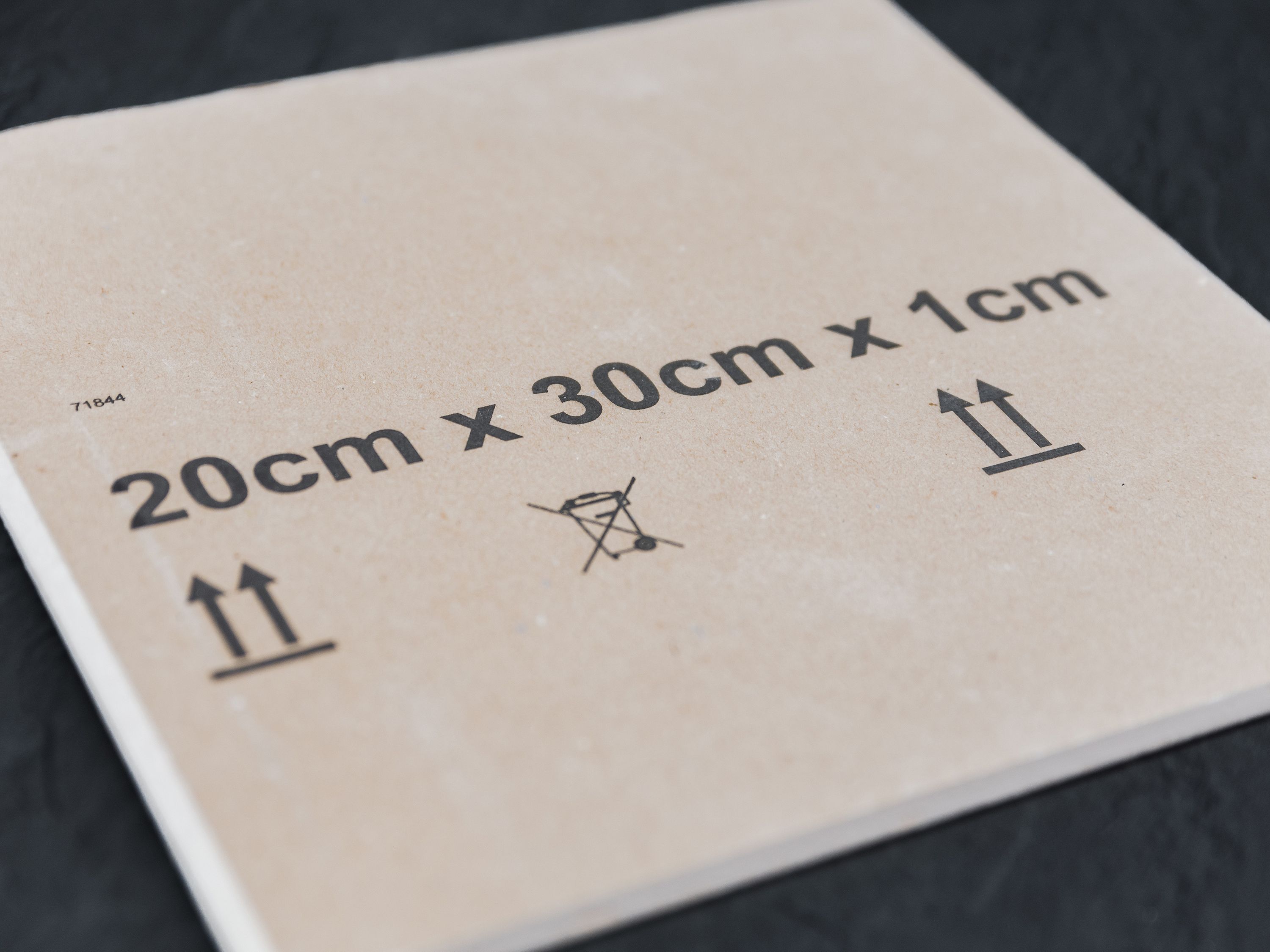

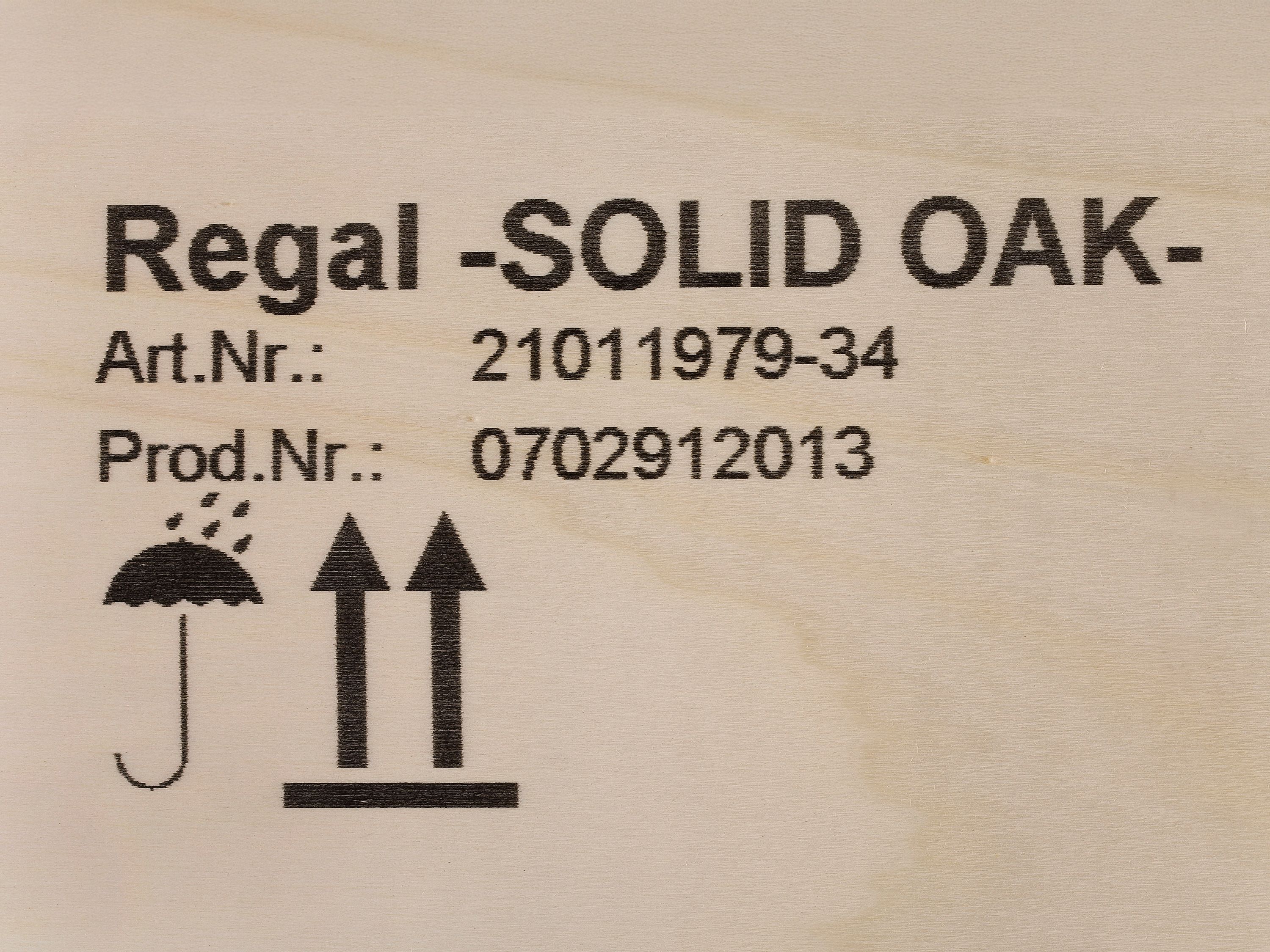

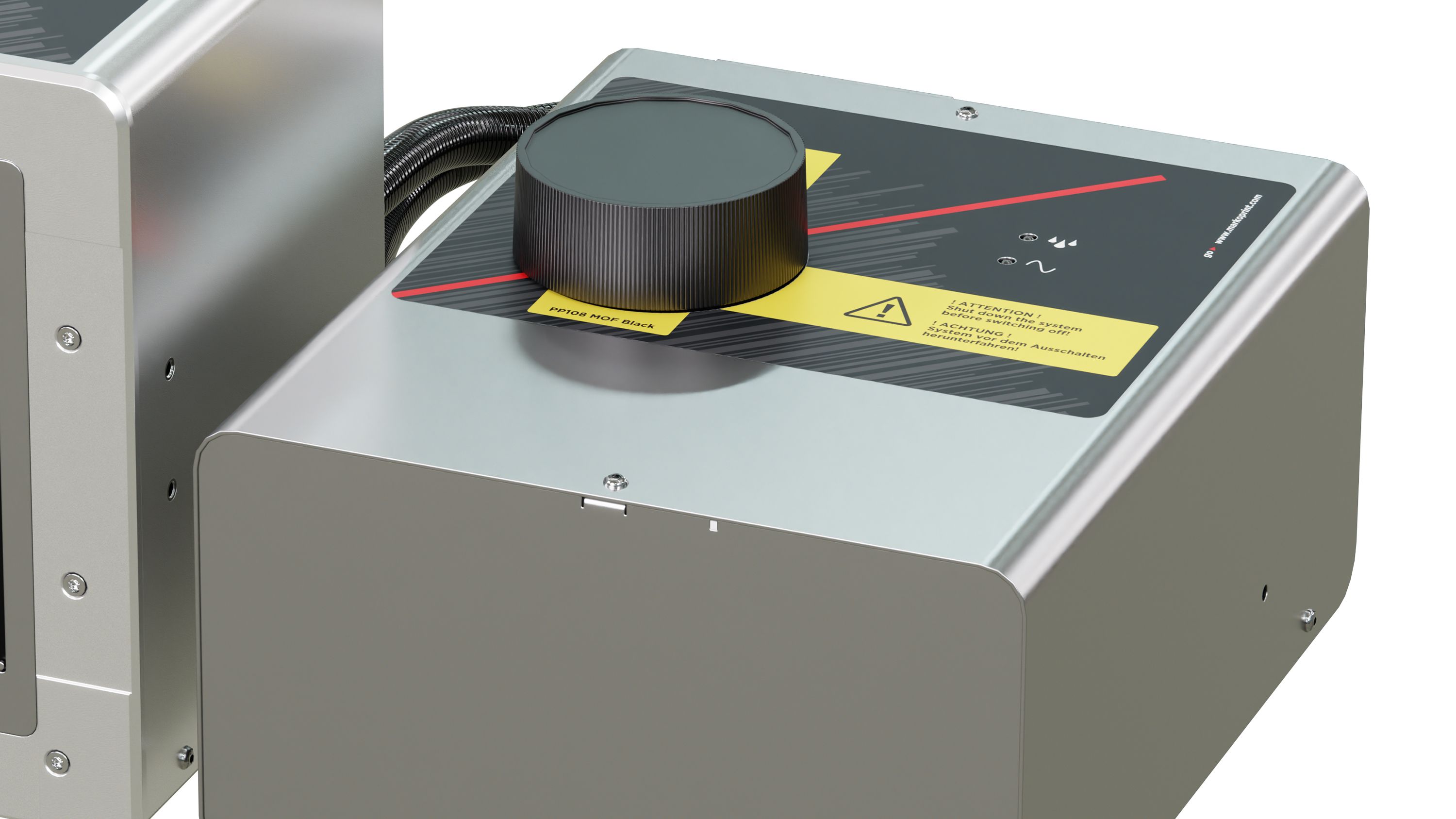

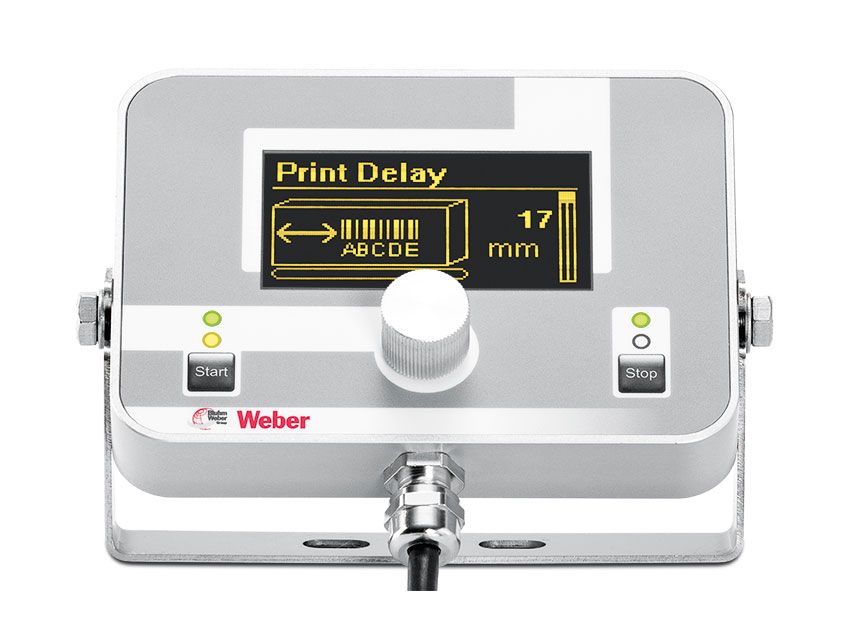

The name of the Markoprint integra PP 108 already reveals its maximum print height of 108 mm. The piezo inkjet printer realises the large character printing required in many industries without offset and prints high-resolution text, 1D barcodes, 2D codes and graphics. This makes it ideal as a labeling alternative. On request, the Markoprint integra PP 108 can also print very small, with a minimum print height of one millimetre. The fast text change with more than 50 variable data per second enables product serialisation, which is particularly important for high-speed labeling in the pharmaceutical and cosmetics industries.

With the Markoprint integra Command software included in the scope of delivery, you can easily create and manage your print layouts on your PC. In addition to a practical ink consumption calculator, the software has many other functions to make your work easier.