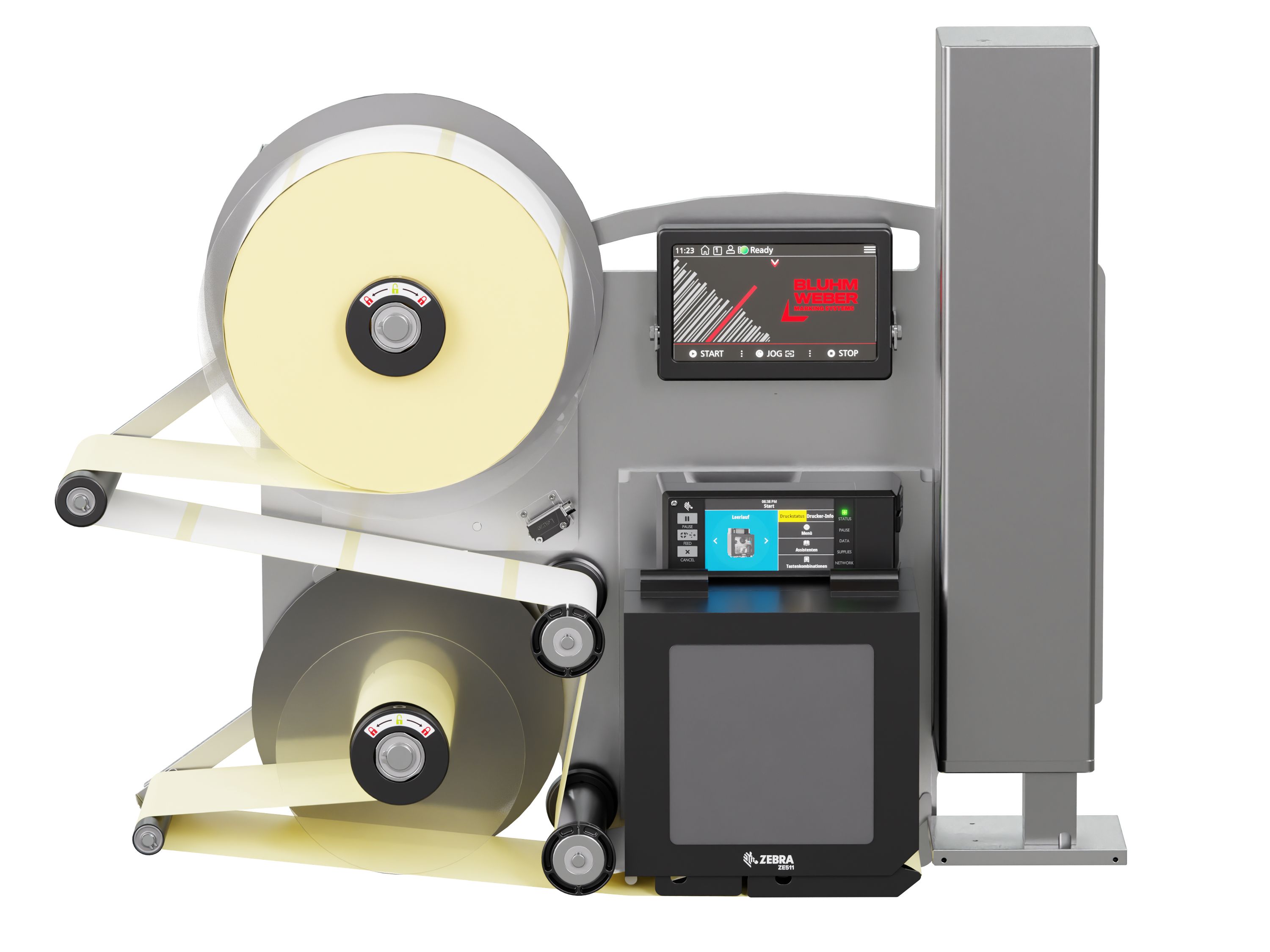

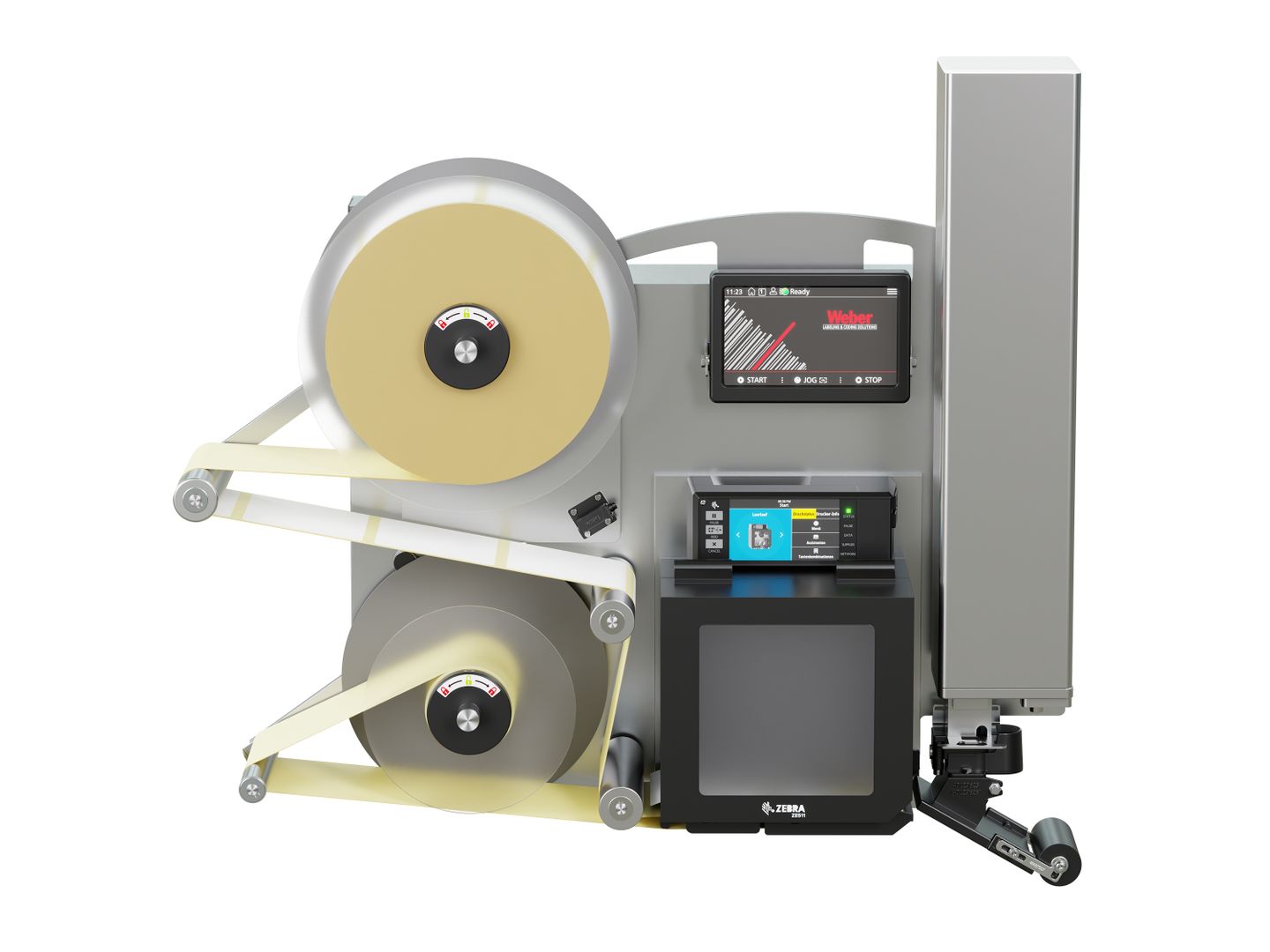

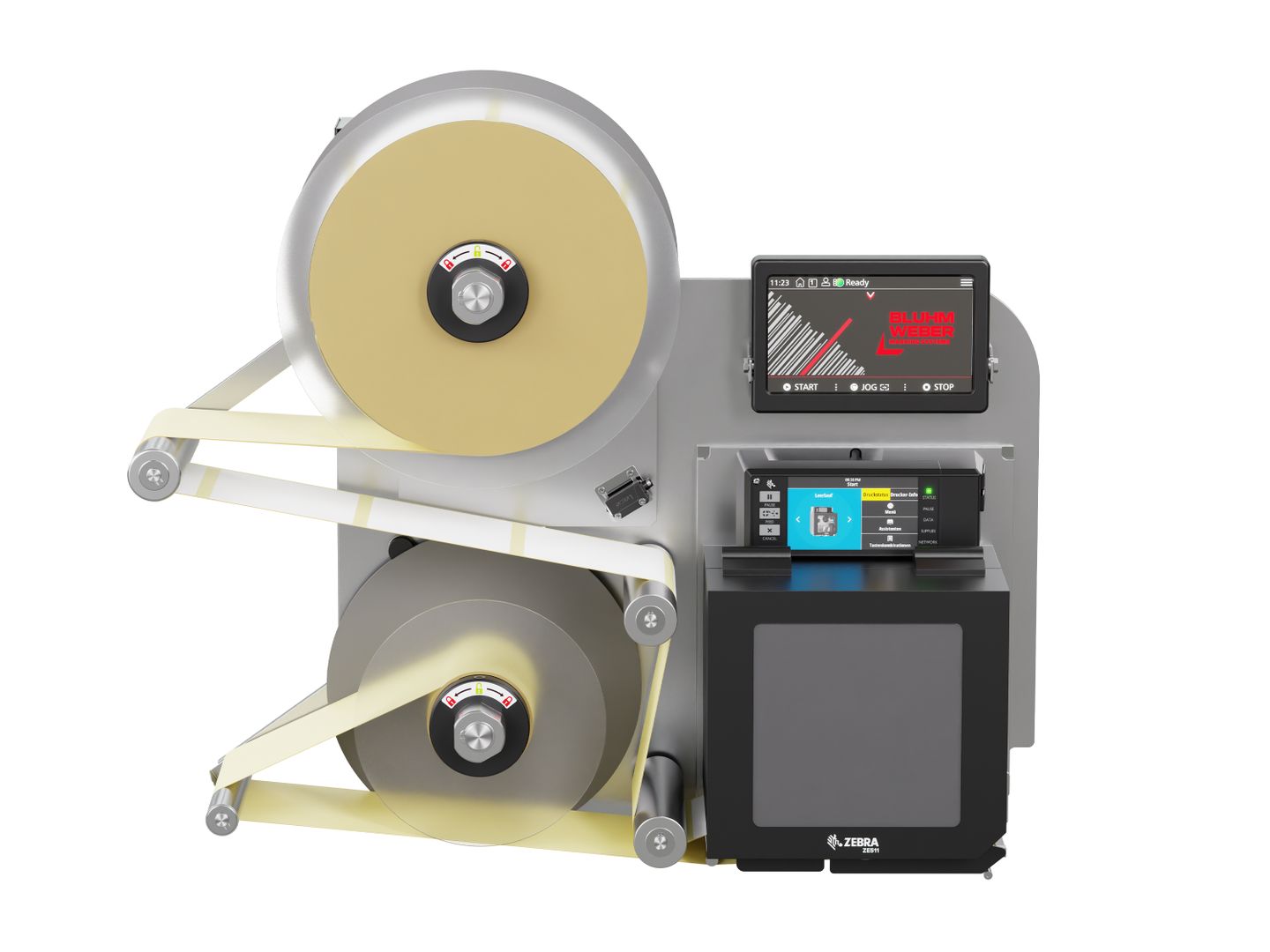

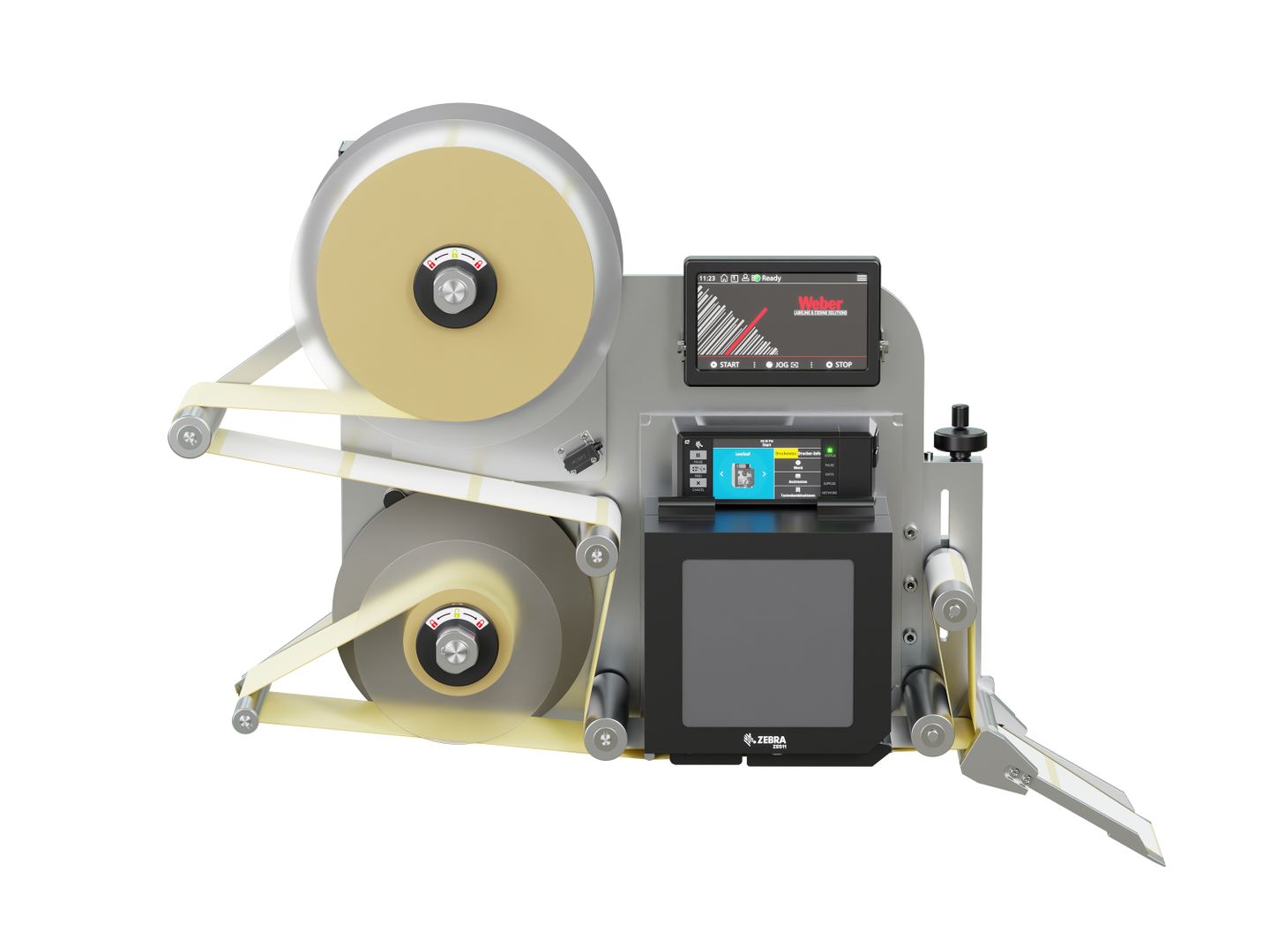

Proven technology with three innovative applicator variants

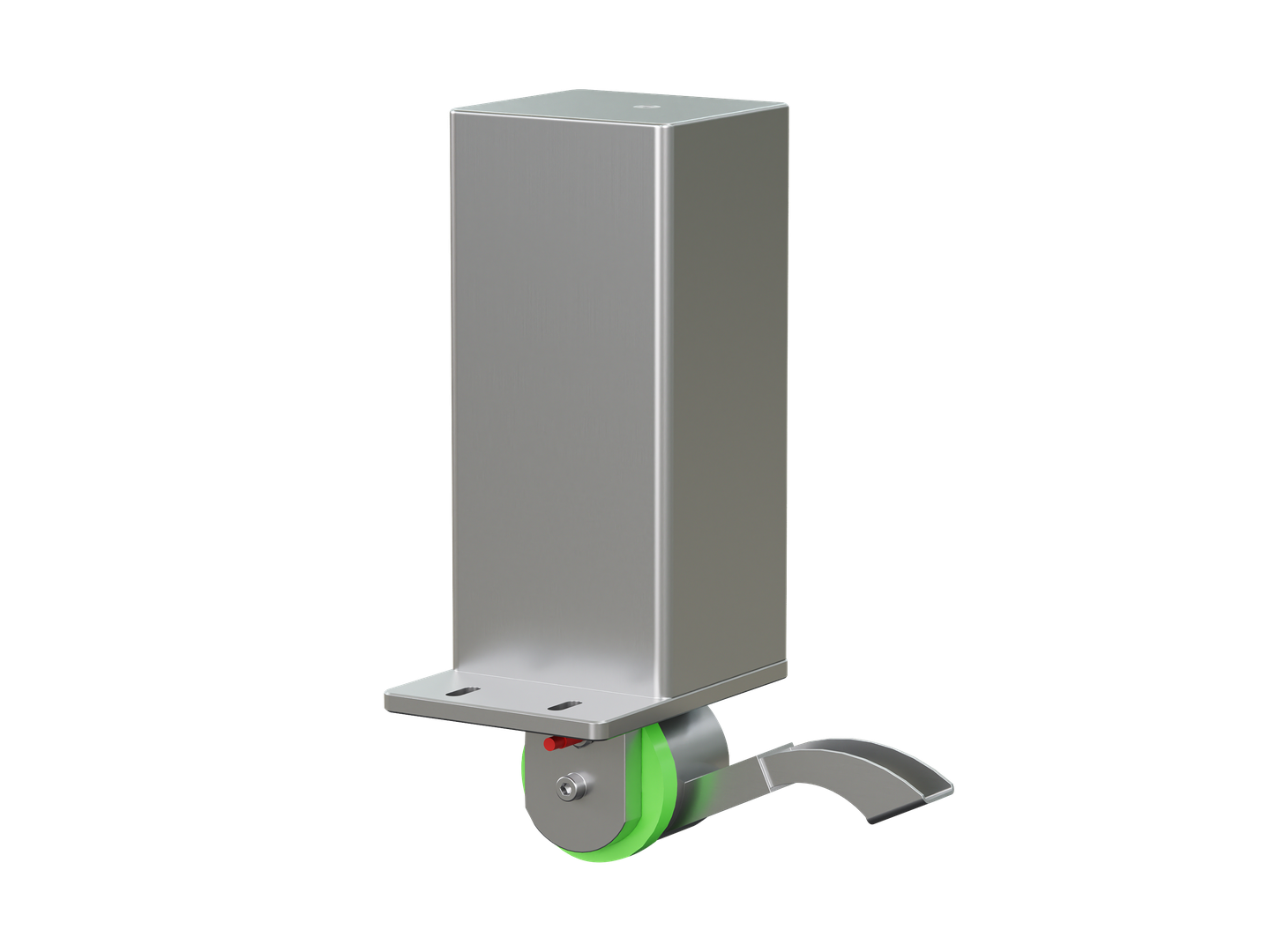

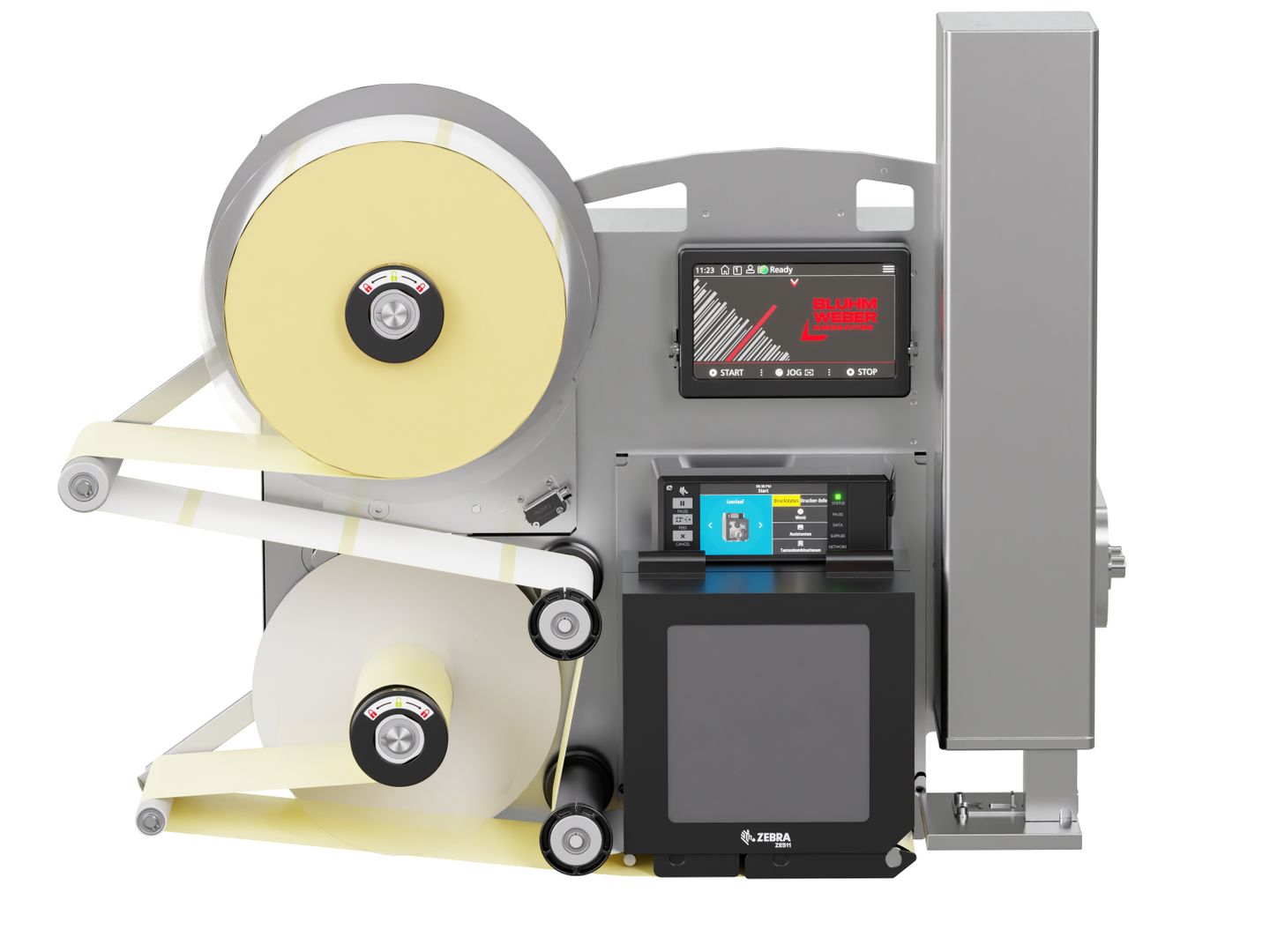

With the Legi-Air 4050B you benefit from proven technology from large-scale production: The versatile print & apply labeling system was developed in a modular design and can be easily integrated into existing processes. It prints either in thermal transfer or direct thermal mode and applies labels to stationary or moving products. High-performance print modules from leading manufacturers, designed for continuous industrial use, are available.

Thanks to the electric applicators, the system benefits from a significantly reduced compressed air consumption. Three different applicator variants are available:

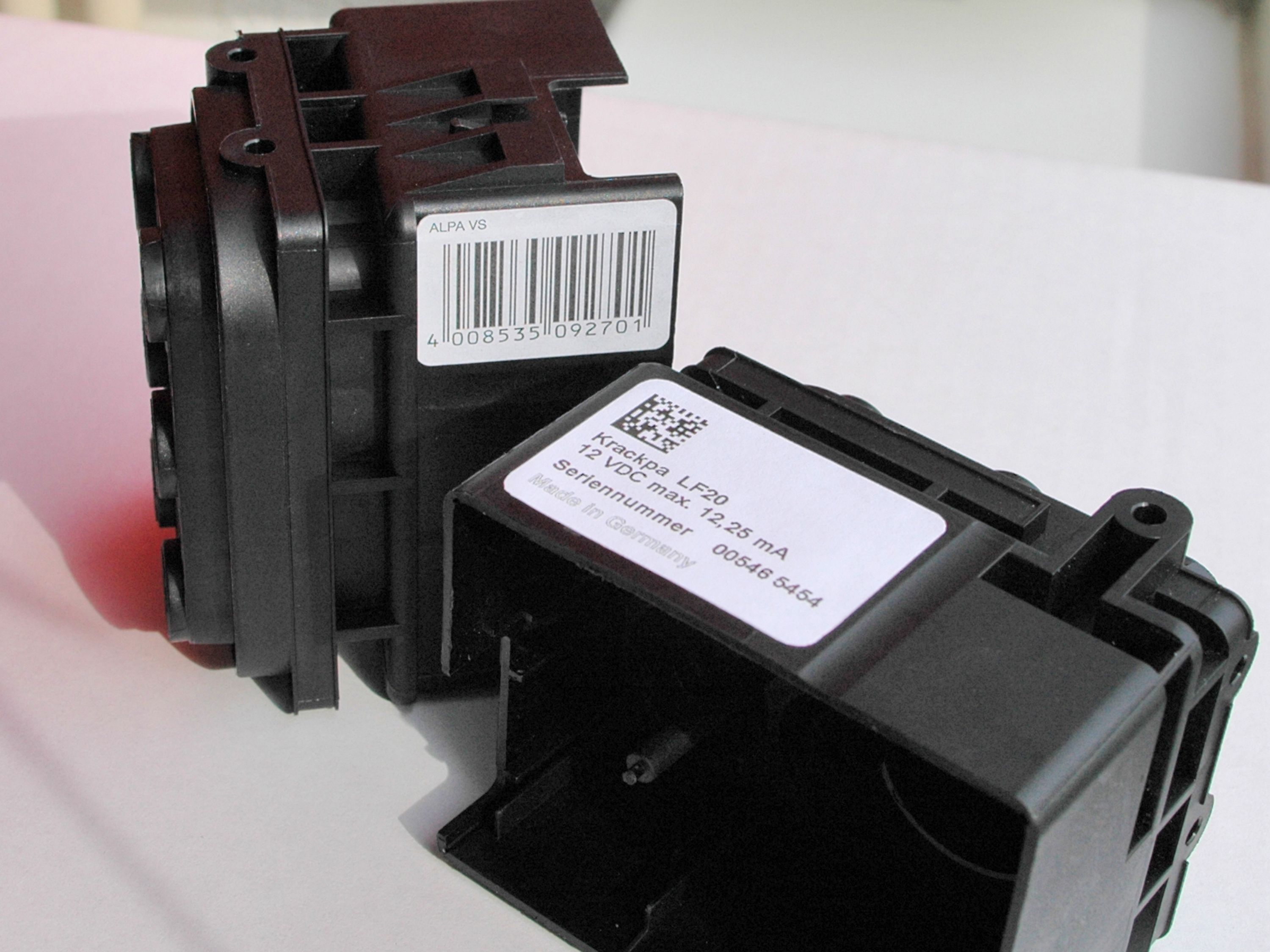

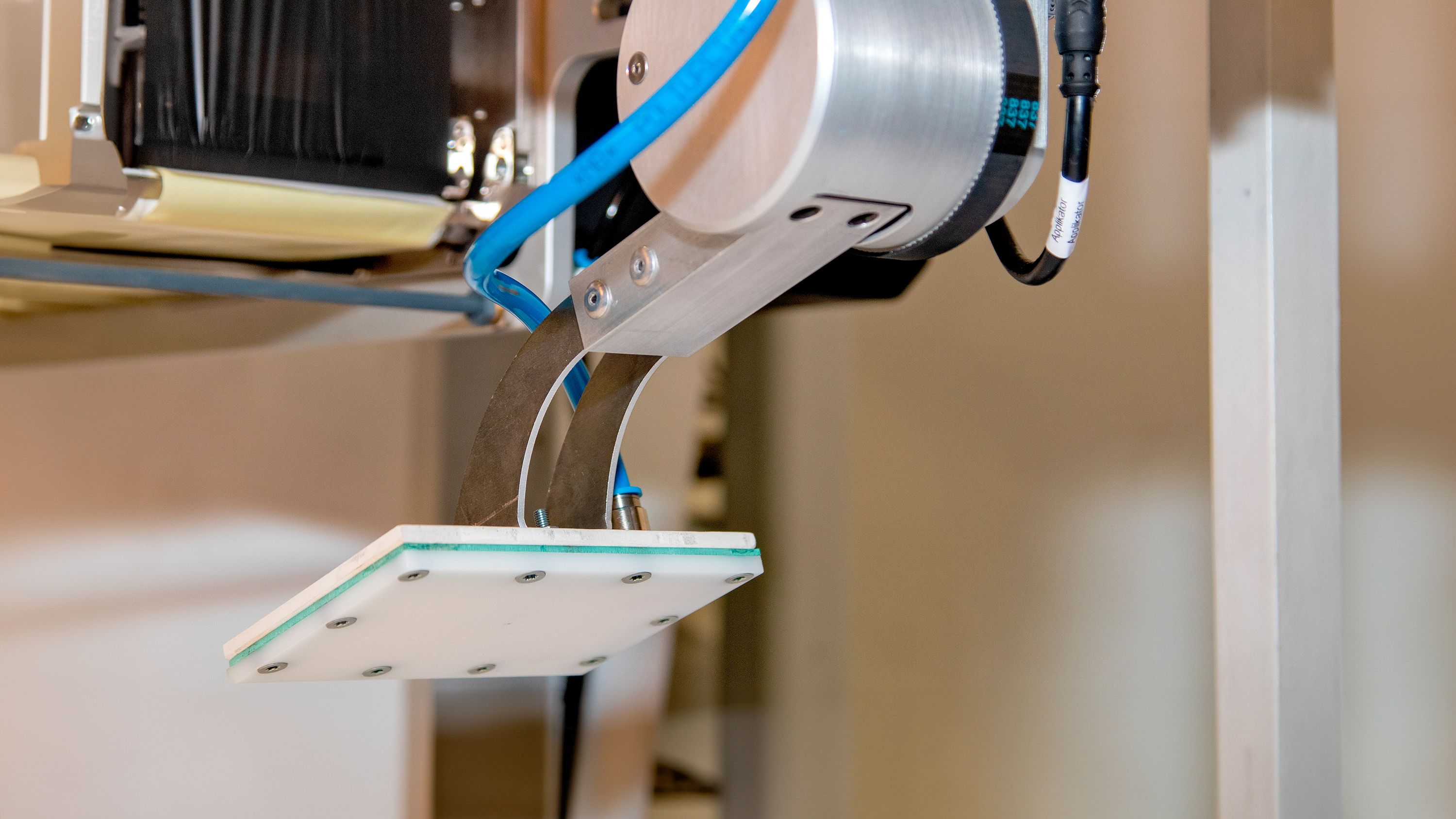

The EL linear applicator for particularly precise labeling of stationary products or uneven product surfaces.

The ES swing applicator with its 90-degree angle is ideal for front, rear, or end-face labeling.

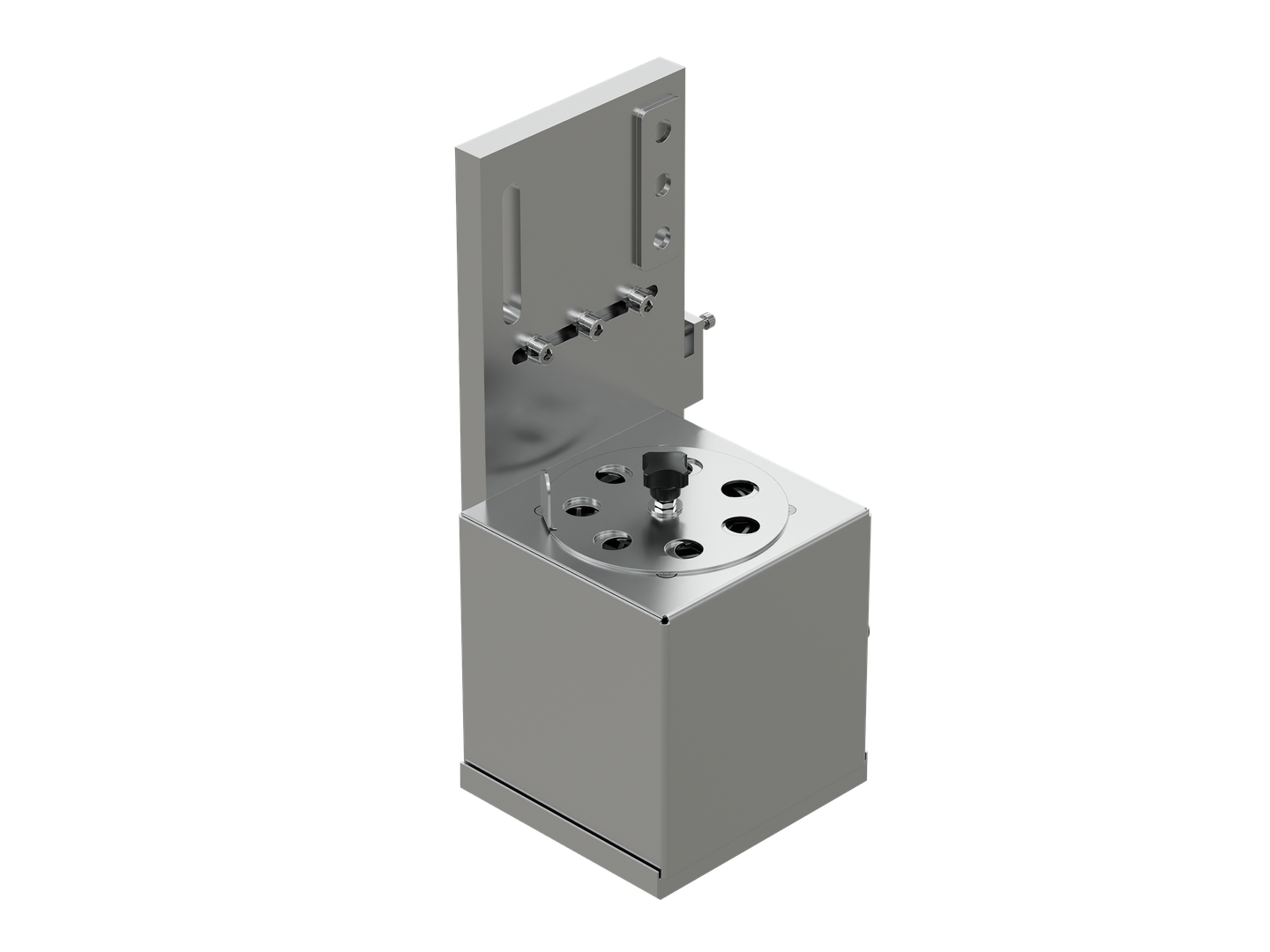

The BB Blowbox offers non-contact high-speed labeling in continuous operation.