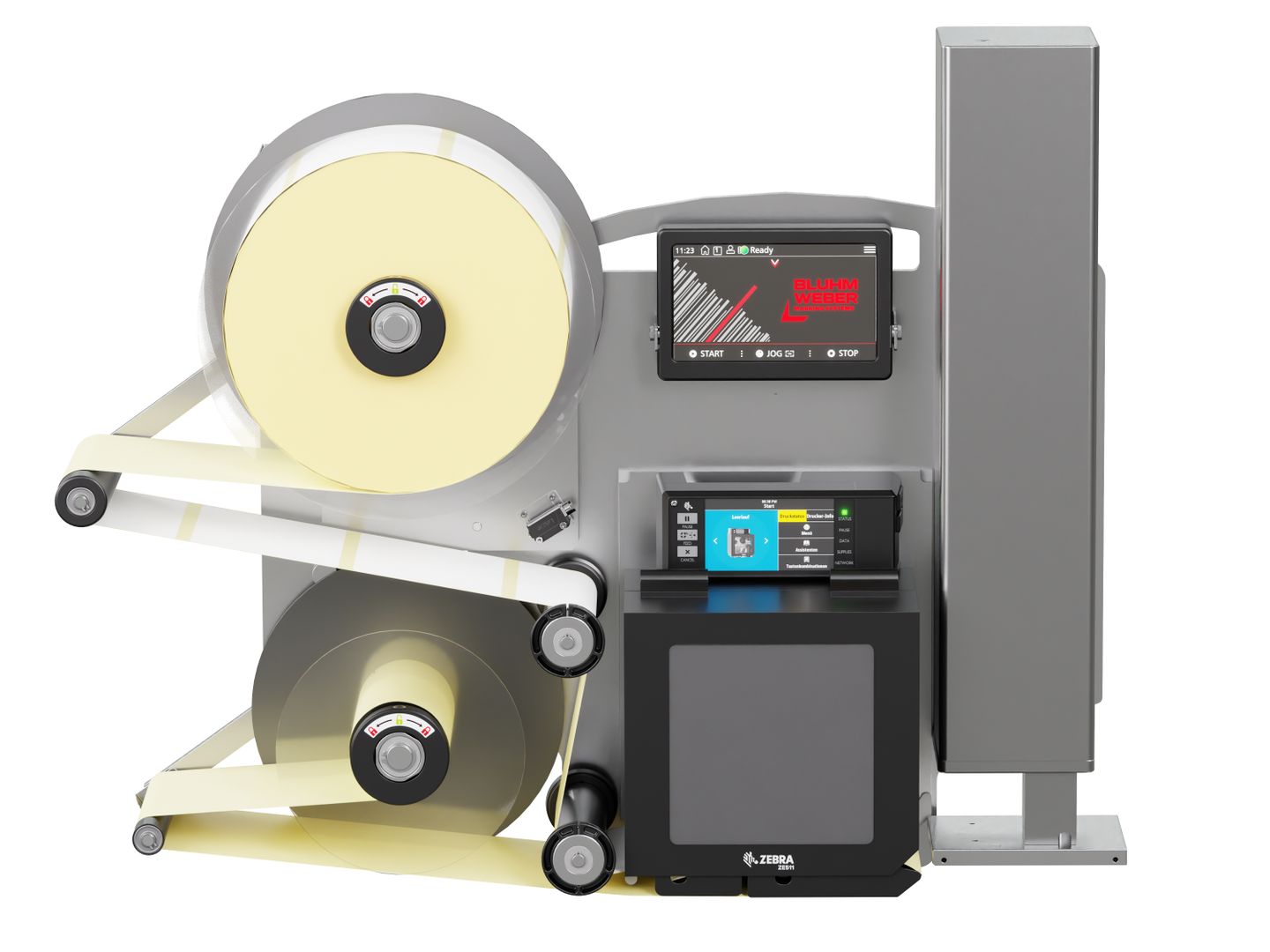

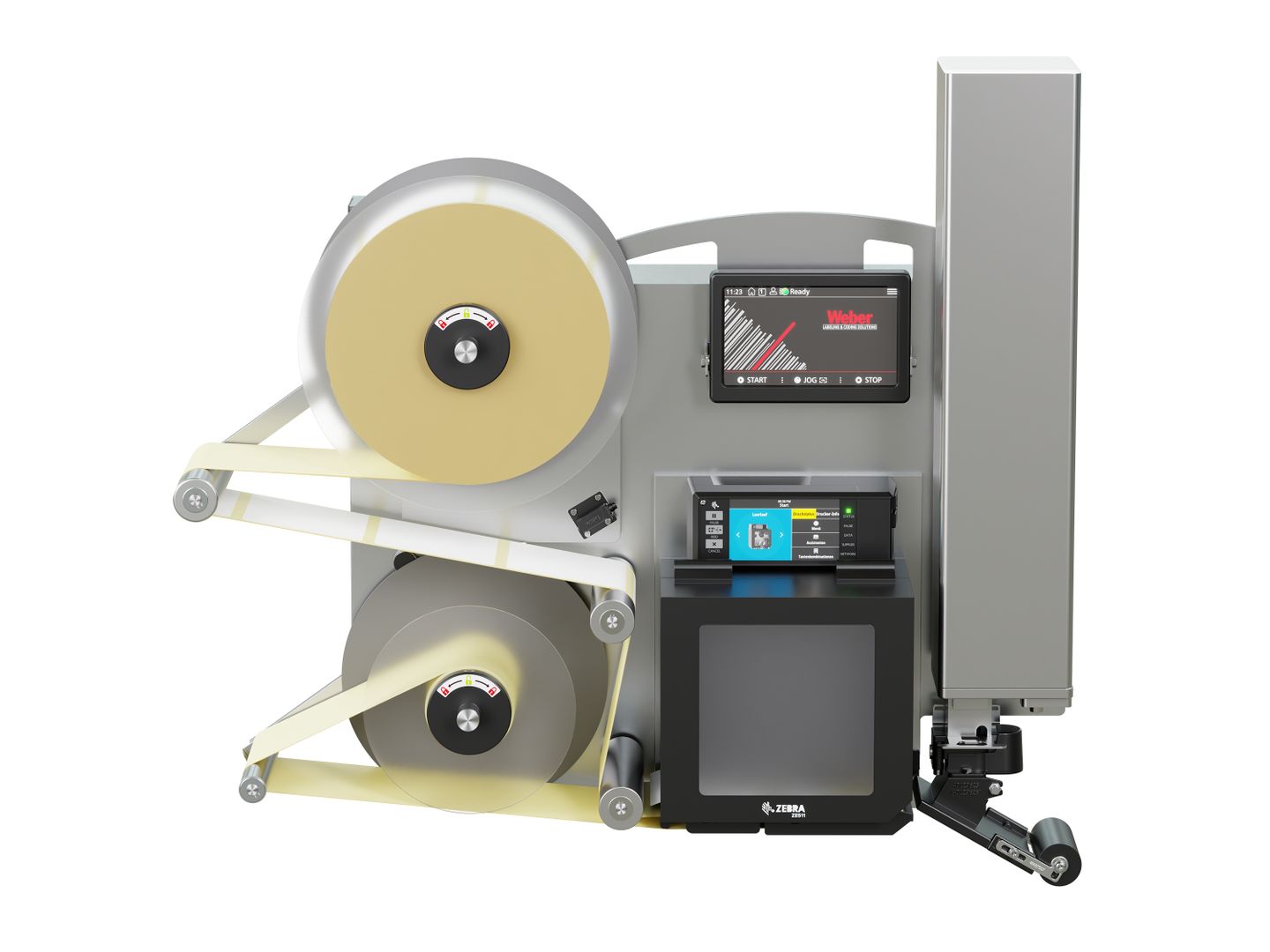

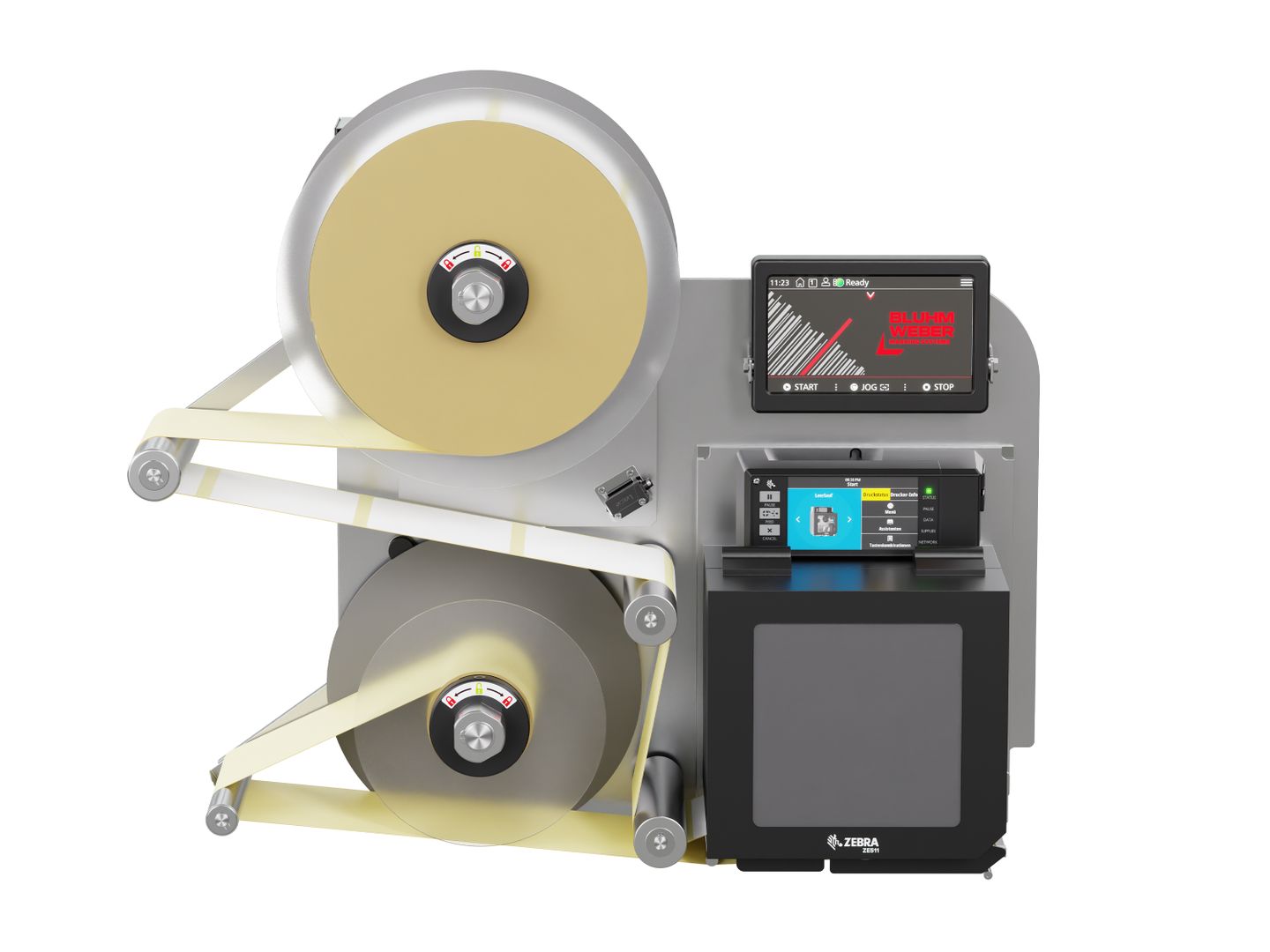

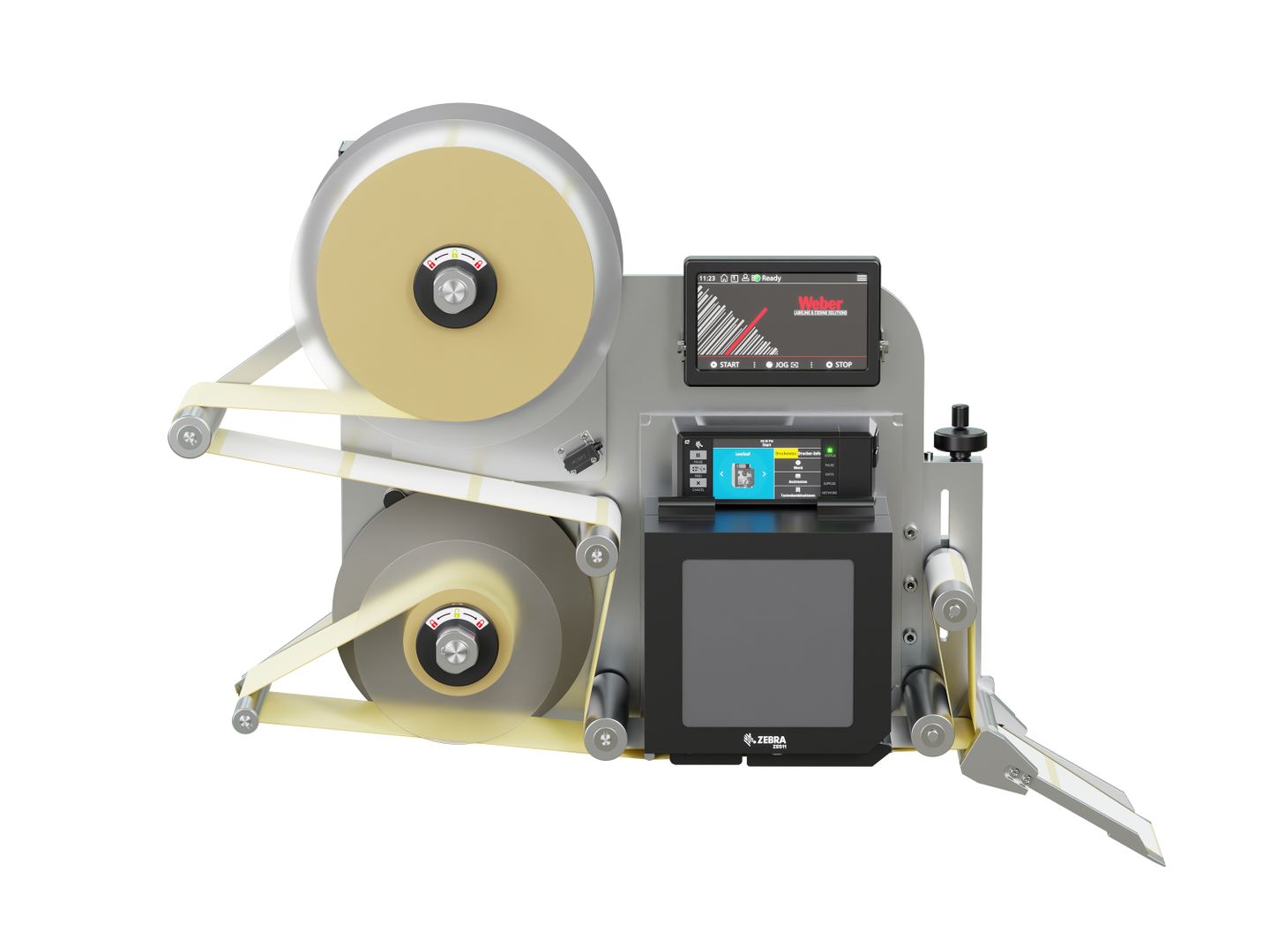

Over-corner labeling without modification for maximum flexibility

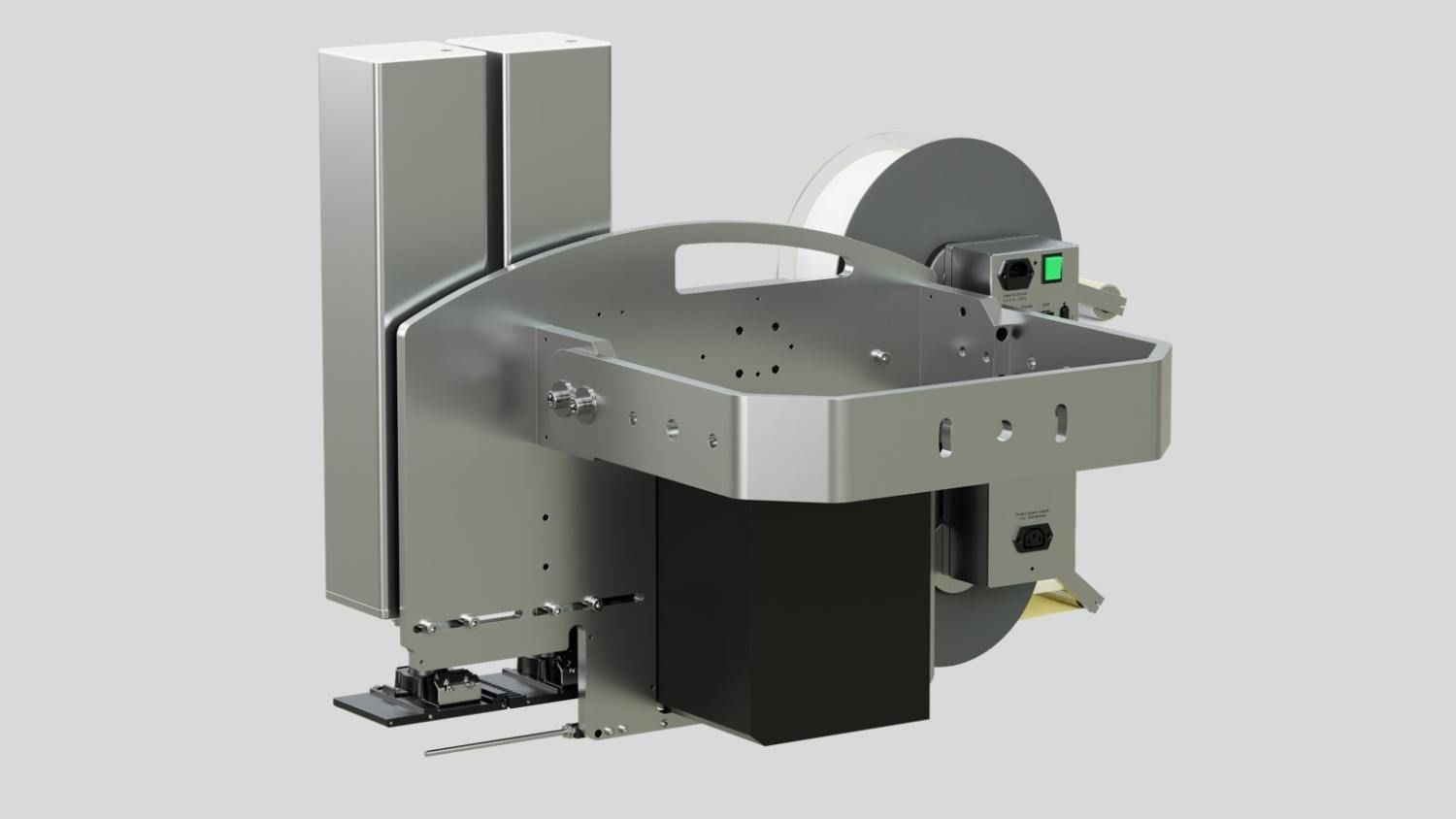

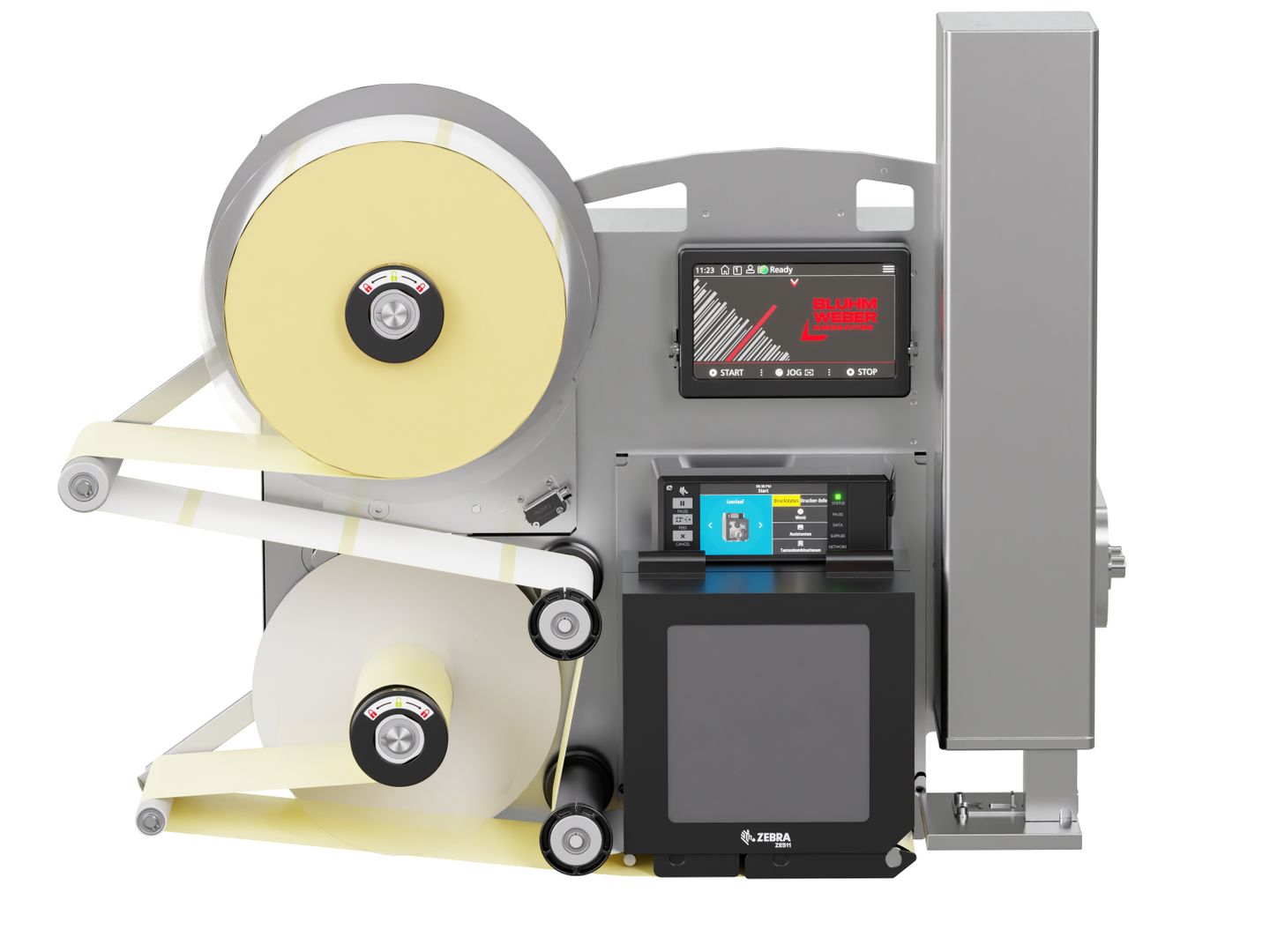

The CE-compliant Legi-Air 4050CWB is the perfect solution for corner labeling. This is particularly advantageous in block-stored warehouses, as commonly found in the pharmaceutical, food, and drugstore industries. Thanks to its innovative application concept, the system labels cartons across two sides with a single label produced in one printing process – maximum data security included. By using electric linear axes and multi-flex tampers, the labels are gently and precisely applied. Particularly practical: switching to single-side labeling or other corner modes can be done tool-free and without conversion. Even varying product heights and different label formats are handled effortlessly by the 4050CWB. With a printing speed of up to 400 mm/s, positioning accuracy of up to 1.5 mm, and CE compliance without additional protective measures, it offers maximum efficiency, flexibility, and safety – even with challenging label qualities.