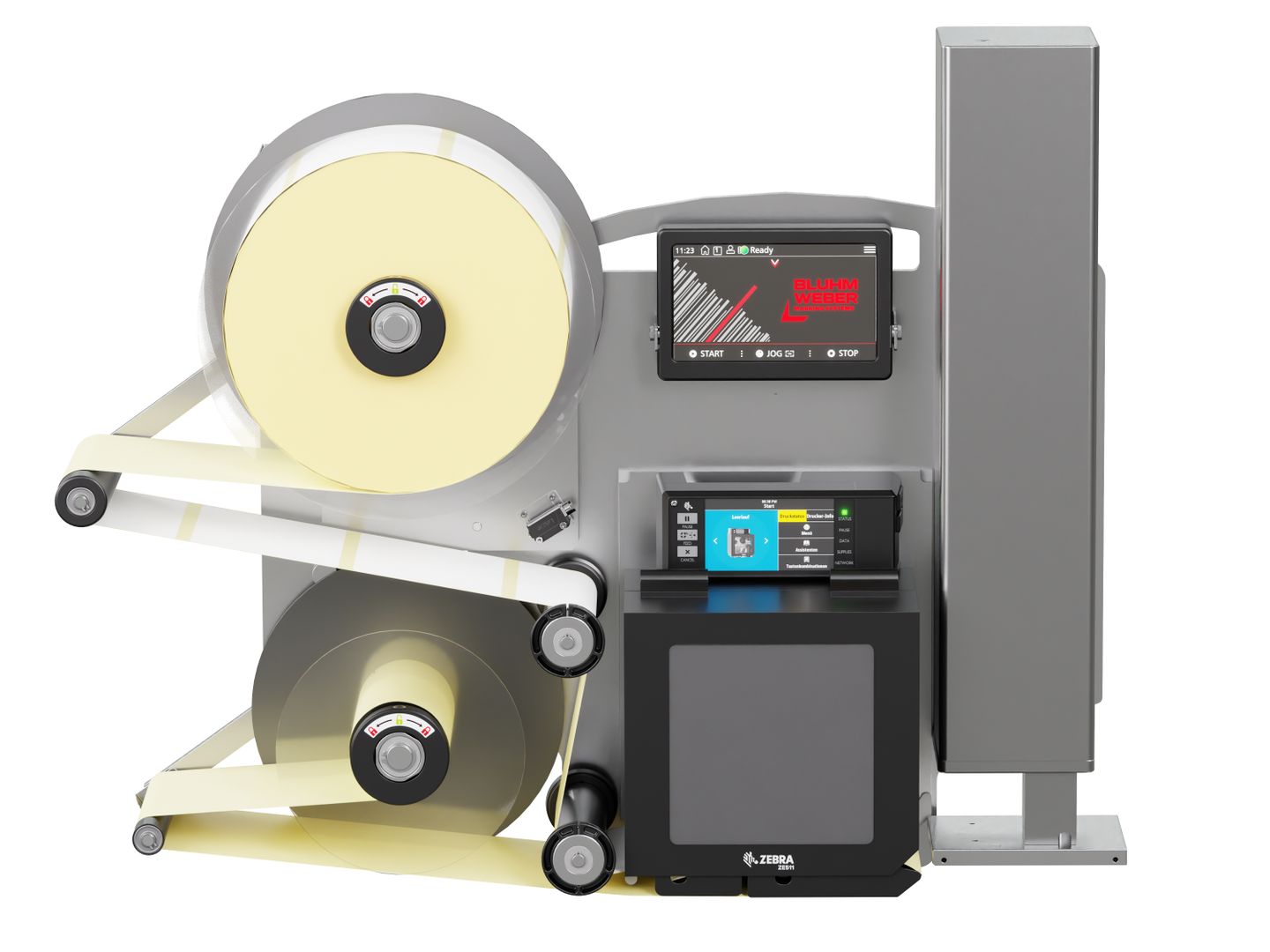

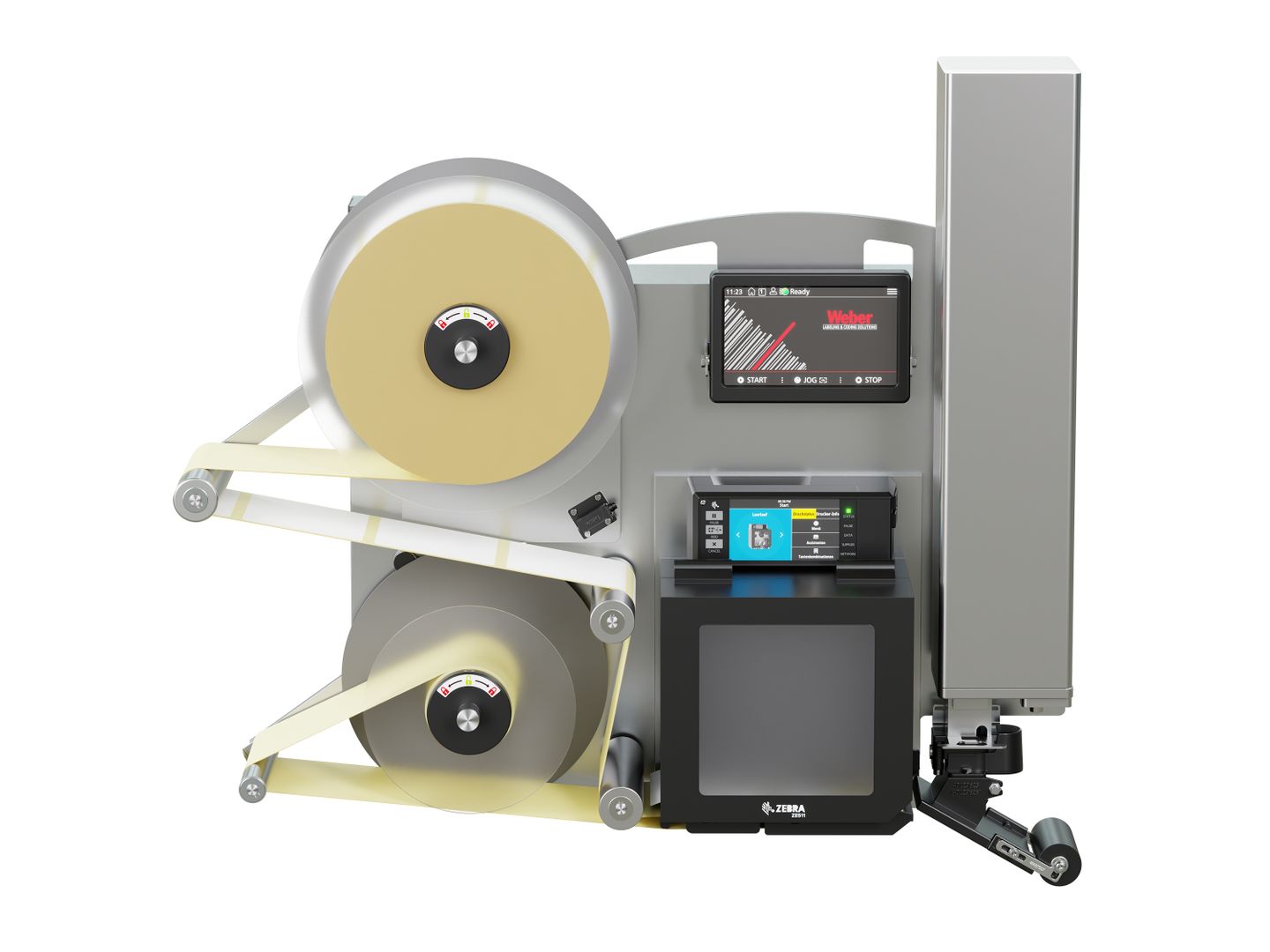

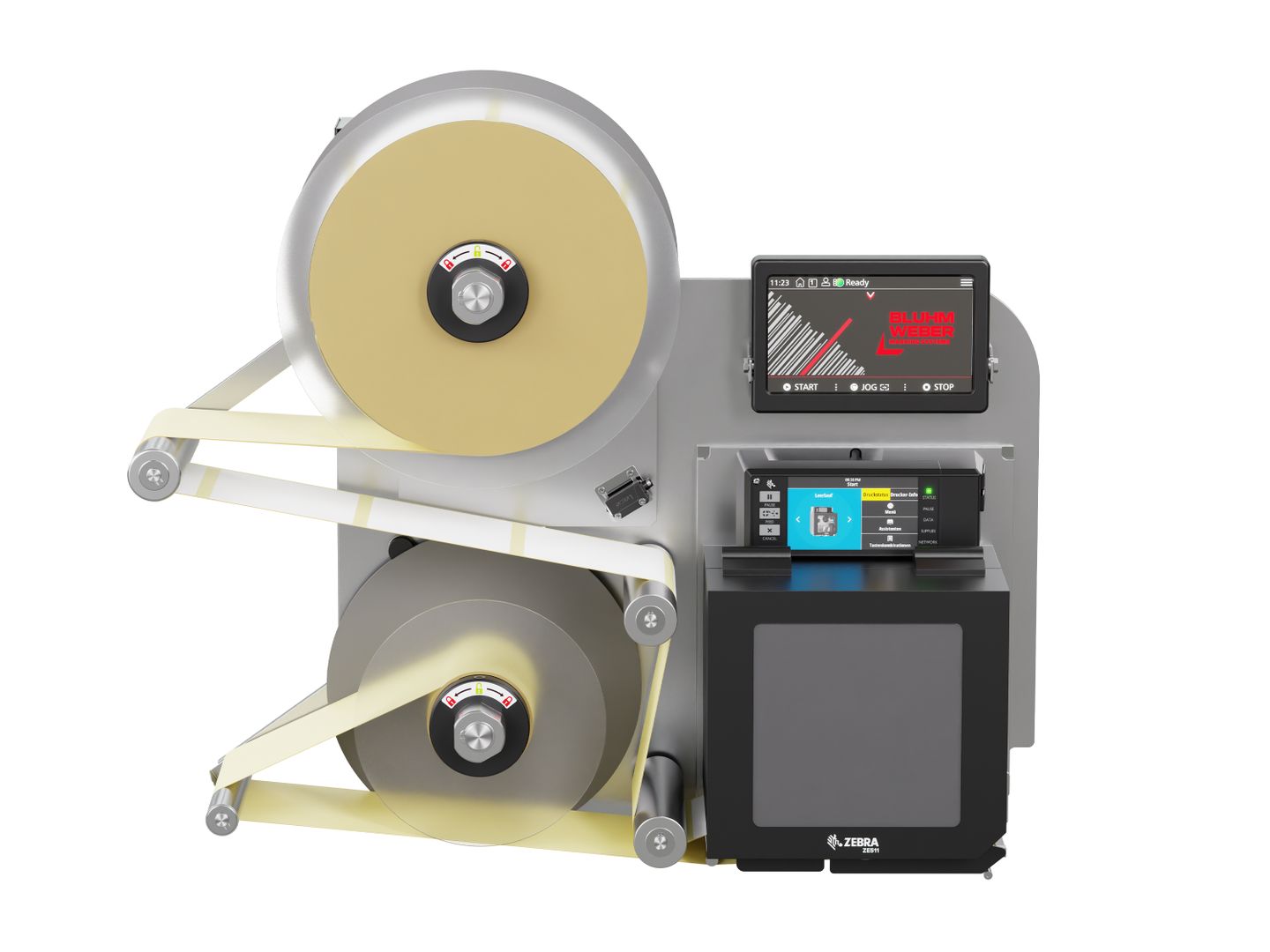

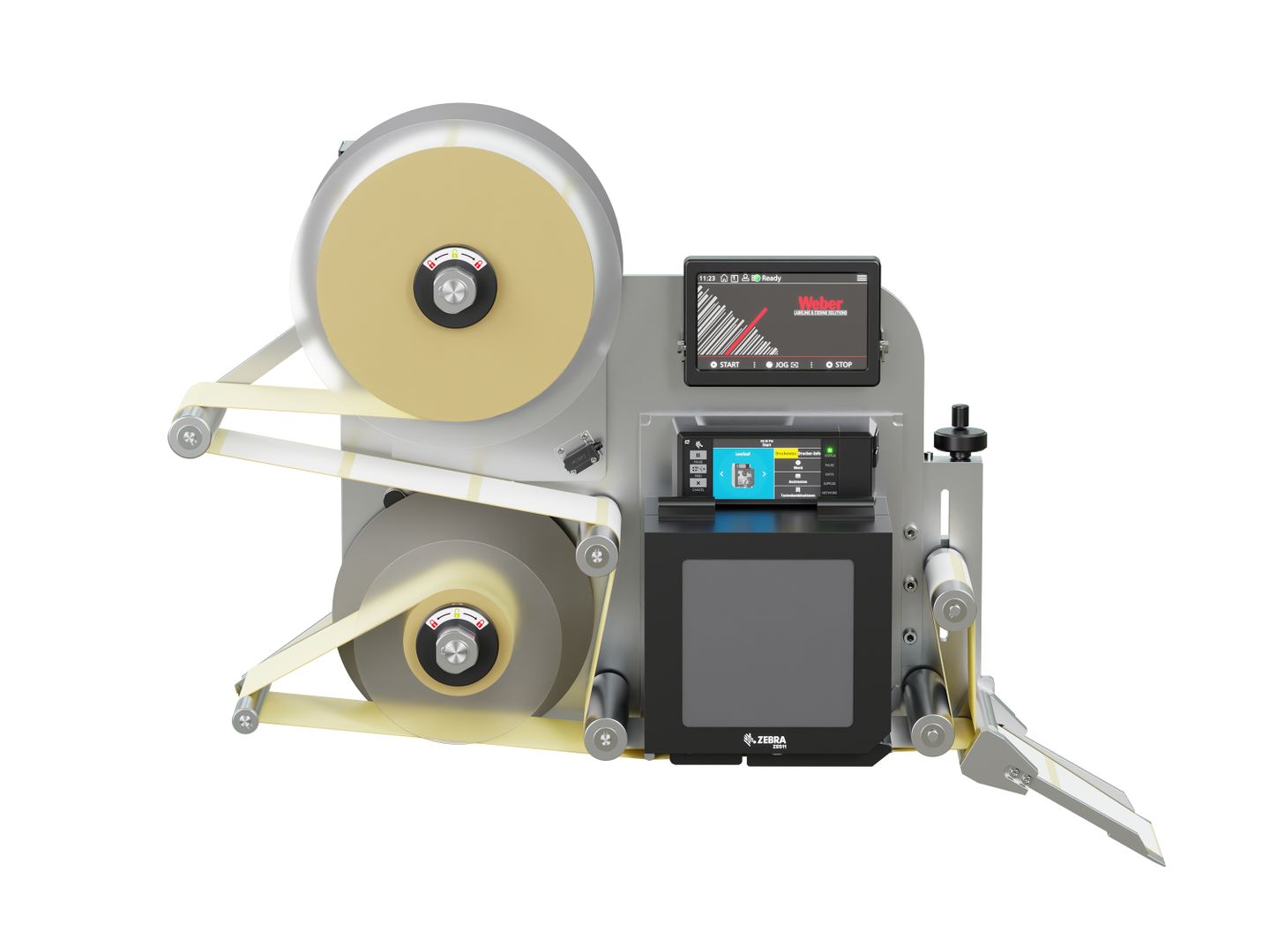

Faster labeling thanks to label liner buffer

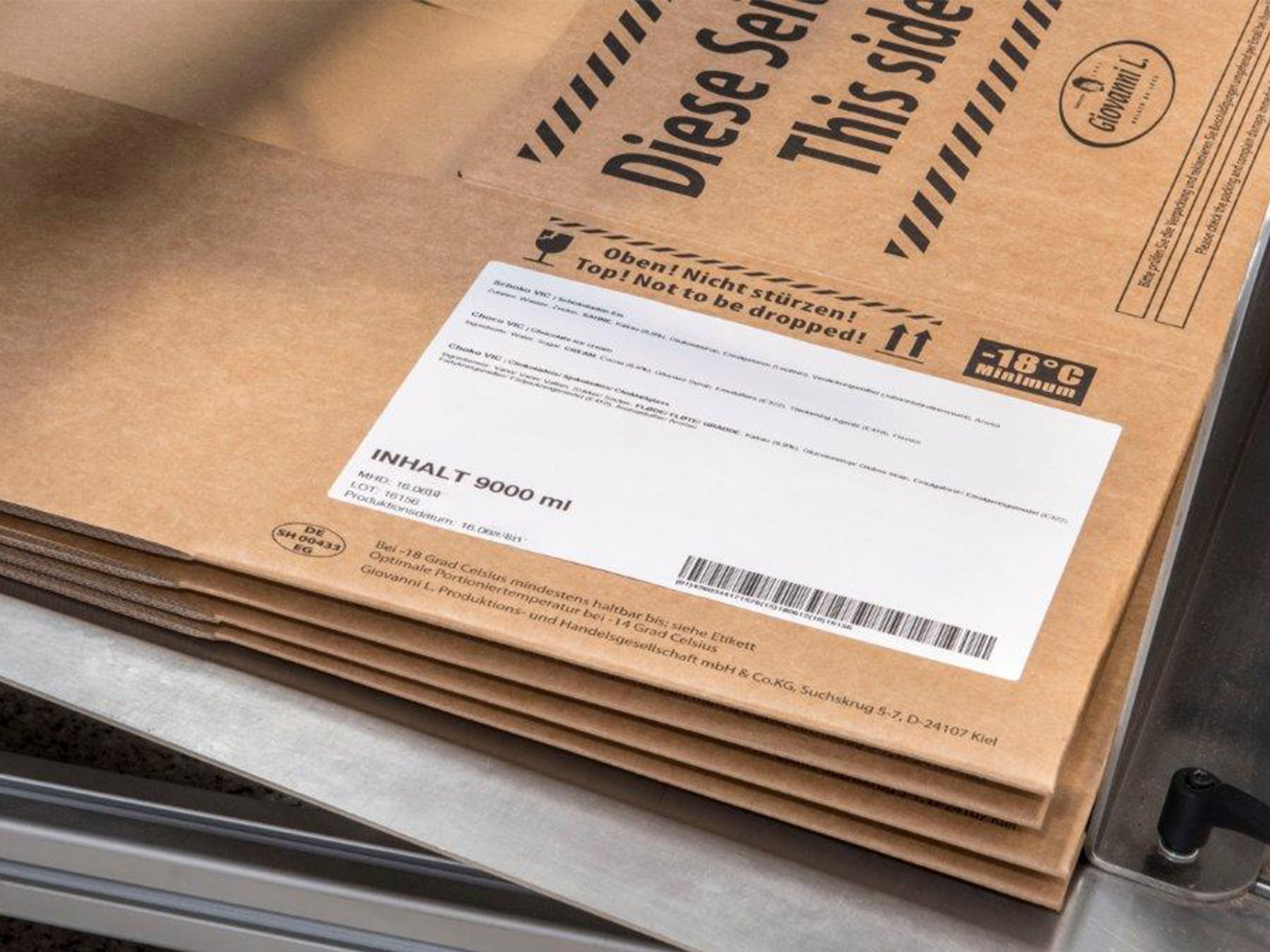

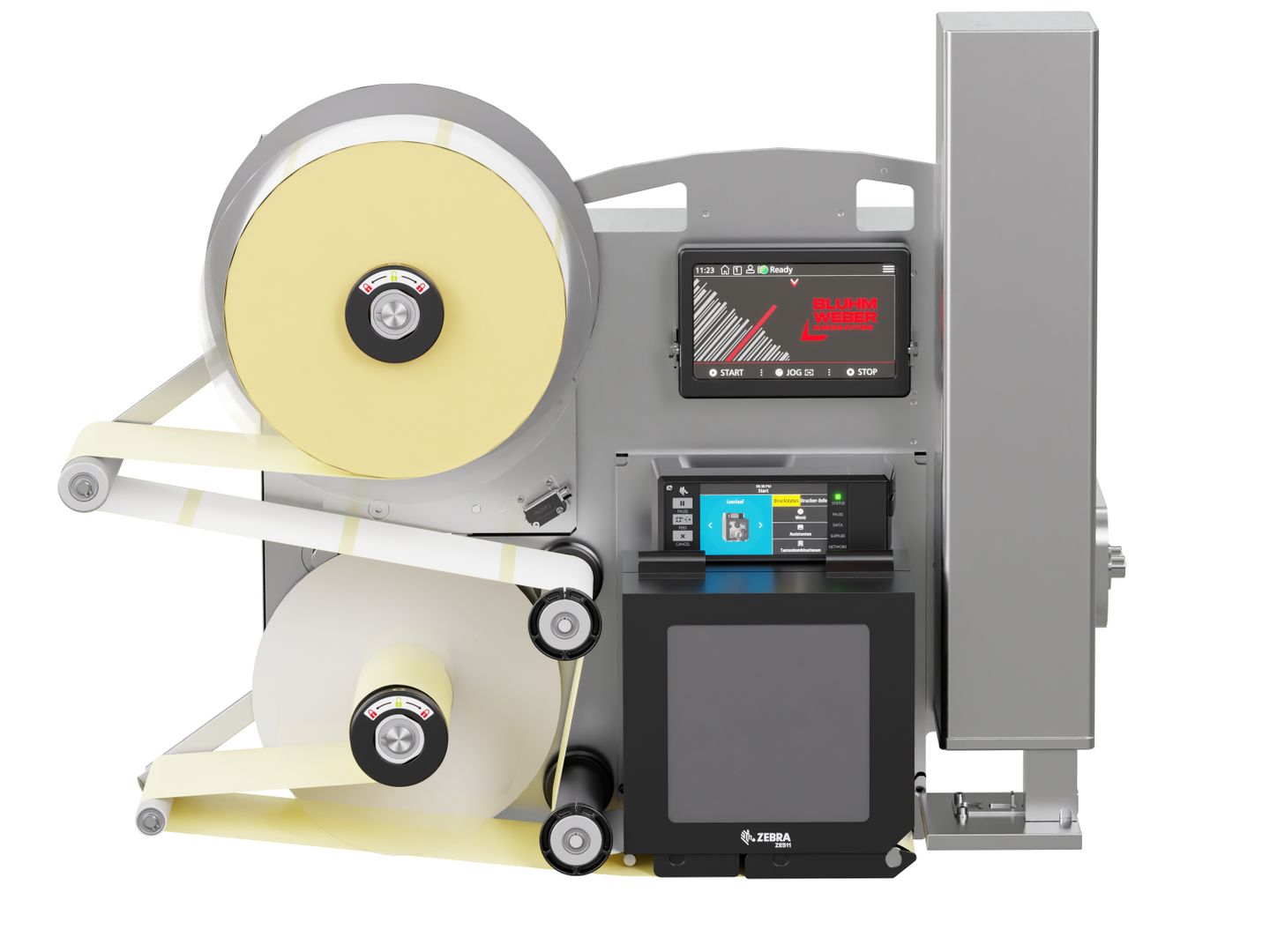

The Legi-E 4050AC is the perfect solution for anyone who wants to combine maximum labeling speed with maximum precision. A label liner buffer allows printed labels to be stored temporarily so that they can be dispensed onto products at up to 50 m/min - regardless of the print module cycle. Various dispenser modules are available for the Legi-E 4050AC, with a pusher roller or brush on request. This ensures that all types of labels adhere securely. Perfect for labeling cartons and outer packaging on the top or side.

The Legi-E 4050AC works completely without compressed air, which saves operating costs and minimises maintenance. The compact design and easy handling make it ideal for a wide range of production environments. Thanks to the wipe-on dispensing process, labels are applied gently and accurately - even when conveyor speed change or the conveying system stops briefly. Automatic calibration to the relevant format saves time and prevents mislabeling.