The barcode is the most important part of the packaging as it allows for automatic identification (AutoID) and recording data about the product. You can spice up such an important part of the packaging with colour, but beware… some colour combinations affect the readability of a barcode.

Bad colour combinations can result in errors when scanning. These are not only annoying during scanning. They also slow down processes, cause correction costs and problems in the supply chain. That is why you need to print a good barcode and use the right colour combination.

1. Best practice: black on white barcodes

Barcode scanners require a certain amount of light/dark contrast between the bars and gaps of barcodes so that their sensors can optimally detect and evaluate the reflected light.

The reflection difference between light and dark elements is called Print Contrast Signal (PCS). If you don’t want to take any risks with the scanability, make sure it is not lower than 80 %.

Black and white makes for the highest contrast. Therefore, it is the most reliable and common combination for industrial markings, such as those made with barcode labels. They are usually produced via so-called thermal printing methods and include barcode labels, GS1-labeling and LPN-labeling.

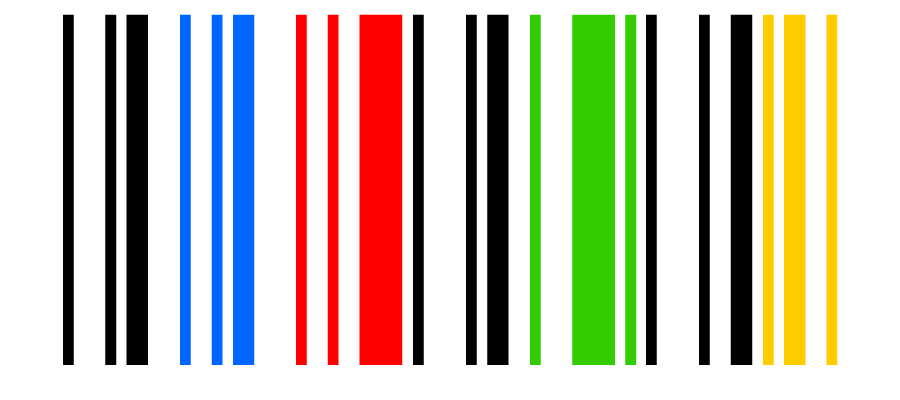

2. The right barcode colour match

The rule is quite easy: always put dark colours on light backgrounds.

These are the right colour combinations for a barcode.

3. Bad colour combinations for barcodes

There are bad colour combinations for which you can sometimes do a trick.

Light on dark

Barcode colours must not be reversed! If the background is dark and cannot be changed or covered, there is a trick: Print white spaces instead of black bars!

Light / light & dark / dark

Light stripes on a light background or dark stripes on a dark background are unsuitable because the contrast between the colors is usually insufficient for scanners.

Red / white

Barcode scanners use red light or infrared light. This creates reflection on red surfaces, which are then interpreted as white. If the background is then light, there is insufficient contrast. Other shades with a high red, pink or orange content are also not suitable in combination with light colours.

Barcode scanners use red light or infrared light. This creates reflection on red surfaces, which are then interpreted as white. If the background is then light, there is insufficient contrast. Other shades with a high red, pink or orange content are also not suitable in combination with light colours.

Green / black & blue / black

Because green is the complementary colour to red, green also has a drawback with barcodes. Green swallows the scanner’s red light and is then interpreted as black. Similarly, turquoise and blue shades do not make a good team with dark colours either.

Metallic colours

Shiny metallic colours and shimmering effects are problematic because they can reflect too much light. As a result, the barcode scanner can no longer distinguish between bars and white spaces.

Patterns / transparency

It is probably already clear that patterned backgrounds are not suitable for reliable barcodes. The same applies to transparent surfaces that let the dark contents of the package shine through, which can reduce contrast.

4. Possible alternative: Datamatrix code

Data matrix codes are two-dimensional barcodes and offer a few more advantages. Since a contrast of only 20 % is sufficient for most 2D barcode scanners, they allow more design options. In addition, they require less space and can therefore be integrated even more discreetly into the packaging design. Learn more about them here:

Data matrix codes are two-dimensional barcodes and offer a few more advantages. Since a contrast of only 20 % is sufficient for most 2D barcode scanners, they allow more design options. In addition, they require less space and can therefore be integrated even more discreetly into the packaging design. Learn more about them here:

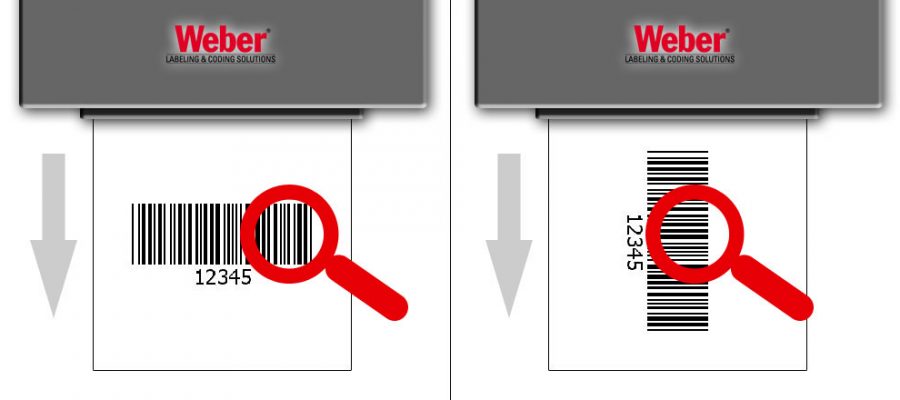

5. Test barcode quality and follow guidelines

When designing barcodes, there is a lot to consider. In some cases, legislators or business partners specify guidelines for product labeling. Incorrect marking could even lead to recalls.

All barcodes used along the supply chain should therefore be thoroughly checked for quality in accordance with defined standards (see ISO/IEC 15416). Many manufacturers install appropriate verification systems in their production lines.

Rely on professional barcode systems

Whether it is label printers, labeling machines or inkjet printers for industrial barcode applications, always look for a reliable partner who will look at your process and work with you to come up with the right solution. Only then can you be sure that your products are properly traceable and that you never get hassle with wrong barcode colours!

Weber Labeling & Coding has more than 50 years of experience in the field of barcodes. The Weber team is always ready for advice and likes to think along with you.

Contact