![]() Most professional and industrial label printers let you choose between two thermal printing methods for label printing: thermal transfer and direct thermal. Which method should you choose for your business application? Here’s everything you need to know for perfect label results!

Most professional and industrial label printers let you choose between two thermal printing methods for label printing: thermal transfer and direct thermal. Which method should you choose for your business application? Here’s everything you need to know for perfect label results!

The difference between thermal transfer printing and direct thermal printing

First, let’s talk about the similarities: Both label printing methods each require a thermal print head that applies heat to the surface being marked. The print head consists of tiny heating elements (dots) that heat up in selected areas to produce the desired print image. Therefore, the rather general term thermal printer may be used for direct thermal label printers as well as for thermal transfer printers. Their printing resolution is determined by the size, number and arrangement of heating elements, specified in dots per inch (dpi). It is usually 203, 300 or 600 dpi. The higher the number, the higher the print resolution and quality.

The actual difference between the two methods is in the surface that is heated by the print head: Thermal transfer printing uses a wax- or resin-based ribbon that transfers ink onto the label when heated. Direct thermal printing, on the other hand, uses heat-sensitive labels which blacken where they are heated directly.

How does a thermal transfer printer work?

In thermal transfer printing, the heating elements of the print head apply punctual heat to the passing ribbon, causing it to melt onto the label and form the print image. The label absorbs the ink so that it becomes part of the media. The ribbon and label stock (material and adhesive) must be carefully matched to each other and to the specific application, in order to receive optimum quality and durability.

How does a direct thermal label printer work?

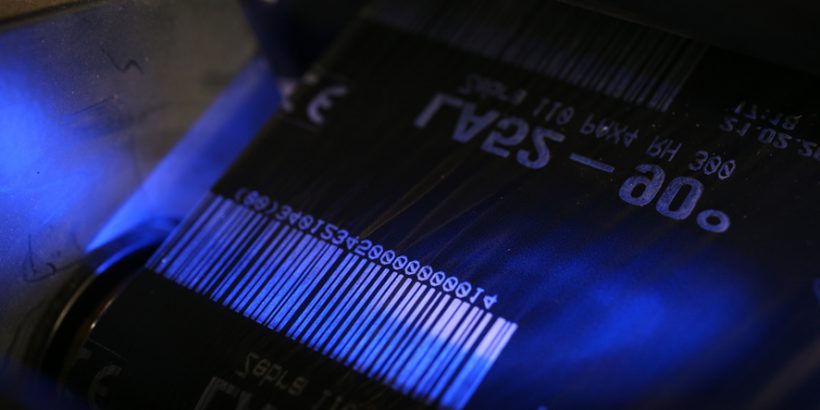

In direct thermal printing, the heating elements of the print head apply punctual heat directly to the passing label, which has a heat-sensitive coating. A chemical reaction causes the label to change color from white to black.

Thermal transfer printing and direct thermal printing for label printing – A comparison

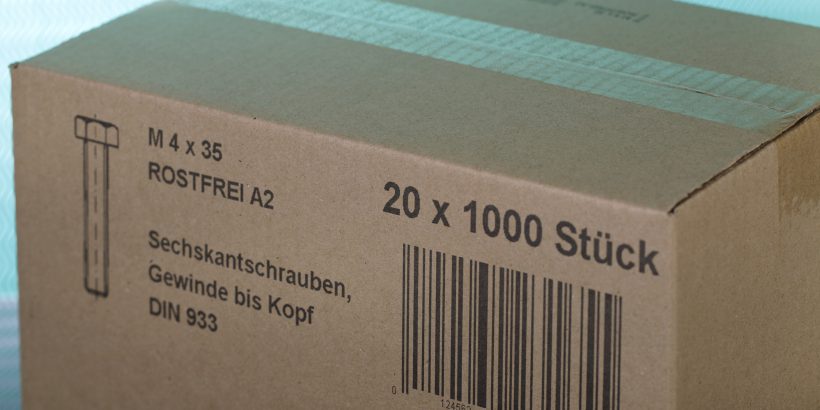

Thermal label printers in general are great to produce barcode labels, because they create high-quality images with excellent edge definition, which is required for barcode scanners to capture data successfully. For more information on this topic, check out our 6 tips for better barcode quality and our quick guide on how to check barcodes without a scanner.

We would also like to add that you can print both linear and two-dimensional barcodes such as data matrix codes or QR codes with either thermal printing method. The same goes for text and graphics, of course.

Let’s compare each method’s performance in different categories:

Thermal transfer | Direct thermal | |

| Print quality | Maximum readability and scannability | Good readability and scannability |

| Print durability | Long-life image stability | Extremely sensitive to heat, light and other environmental conditions (label will darken when overexposed to such) |

| Color printing | Possible with colored ribbon | Only black and white |

| Print head life | Ribbon acts as buffer between print head and label material; ribbon back-coatings reduce static and friction | Direct contact with abrasive labels (and possible dust and debris) promotes wear-out and increased replacement costs |

| Printer configuration and maintenance |

|

|

| Media selection and cost |

|

|

| Environmental aspects |

|

|

| Typical applications | Product and packaging labels, GHS labels, asset tags | Shipping labels, receipts, tickets |

Conclusion

Go for thermal transfer printing if you need durable and high-resolution images, especially for traceability applications and labels that need to withstand abrasion, chemicals and exposure to light and heat. For simple and cost-effective labels with a short shelf life, direct thermal printing might make more sense.

If you are looking for an efficient way to apply your printed labels to packaging alsongside the production line, you might want to have a look at our professional labeling systems that include automatic labels dispensers as well as modular print & apply solutions. You might even want us to check if our industrial inkjet printers can save you costs by replacing labeling with direct marking:

Still not sure or ready to start?

Either way: Contact our team for FREE expert advice and top deals for label printers that best suit your business needs! Weber Marking Systems is an official trade partner for the world’s most popular printer brands such as Zebra, Sato, Epson and Datamax. We offer an excellent global sales and service network for all of our marking systems.

Contact us for more information