The labeling of frozen foods is very specific, since these products are stored under extreme conditions.

Labeling frozen foods

For frozen meat, frozen meat preparations and frozen unprocessed fishery products, the date of freezing must be indicated in accordance with the Food Information Regulation. This is done by stating “frozen on…” followed by the date of the first freezing.

For frozen meat, frozen meat preparations and frozen unprocessed fishery products, the date of freezing must be indicated in accordance with the Food Information Regulation. This is done by stating “frozen on…” followed by the date of the first freezing.

In the case of foods that have been frozen prior to sale and are sold thawed, the words “thawed” shall be added to the name of the prepackaged food. This requirement does not apply to frozen ingredients used in the processing of compound foods and contained in the finished product, foods for which freezing is a technologically necessary step in the manufacturing process, foods for which thawing has no negative impact on the safety or quality of the food.

The challenge of deep-freeze labeling frozen foods

Blast-frozen products are frozen at the time of their labeling. They must be labeled with special frozen labels that not only adhere very well to the frozen adhesive substrate, but also stick later in the thawed state – in the consumer’s kitchen – to meet all the necessary regulations. These labels are coated with frozen adhesives that have special adhesive strength. They are also low-migration, so no substances hazardous to health can transfer to the packaged food. The materials have ISEGA and FDA approval and can therefore be used without restriction for food, including fatty goods.

Blast-frozen products are frozen at the time of their labeling. They must be labeled with special frozen labels that not only adhere very well to the frozen adhesive substrate, but also stick later in the thawed state – in the consumer’s kitchen – to meet all the necessary regulations. These labels are coated with frozen adhesives that have special adhesive strength. They are also low-migration, so no substances hazardous to health can transfer to the packaged food. The materials have ISEGA and FDA approval and can therefore be used without restriction for food, including fatty goods.

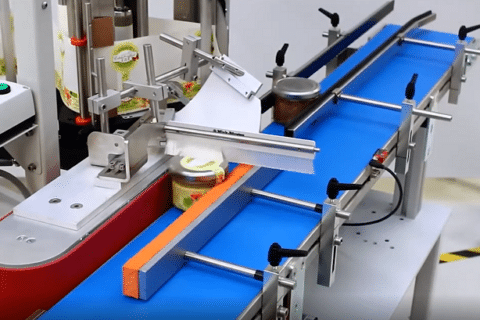

But not only the label material, but also the labeling technology must be able to withstand temperatures of minus 24° Celsius. Here, the cables and bearings have to be adapted to the extreme conditions.

Two-sided pallet labeling at minus 10° Celsius

Ambient temperatures of minus six to minus ten degrees Celsius prevail at the palletizing station of Eisbär Produktions GmbH from Plummendorf. For this reason, the pallet labeler sits in an air-conditioned housing. As soon as a freshly foiled pallet, which consequently needs to be labeled, approaches, the label print dispenser prints the information transferred from the ERP system onto a pallet label and pushes it forward onto the dispensing stamp. Once the corresponding pallet is in position, a pneumatic sliding window of the labeling housing opens and clears the way for the dispensing stamp. The stamp extends, labels the passing pallet at the end face, and immediately moves back again. While the pallet continues to move, the print module pushes another label onto the dispensing stamp. The applicator extends again, labels the pallet at the side and disappears back into the housing. The sliding window closes and the pallet moves on to the high-bay warehouse.

Ambient temperatures of minus six to minus ten degrees Celsius prevail at the palletizing station of Eisbär Produktions GmbH from Plummendorf. For this reason, the pallet labeler sits in an air-conditioned housing. As soon as a freshly foiled pallet, which consequently needs to be labeled, approaches, the label print dispenser prints the information transferred from the ERP system onto a pallet label and pushes it forward onto the dispensing stamp. Once the corresponding pallet is in position, a pneumatic sliding window of the labeling housing opens and clears the way for the dispensing stamp. The stamp extends, labels the passing pallet at the end face, and immediately moves back again. While the pallet continues to move, the print module pushes another label onto the dispensing stamp. The applicator extends again, labels the pallet at the side and disappears back into the housing. The sliding window closes and the pallet moves on to the high-bay warehouse.

Marking frozen ice containers

For traceability purposes, every single ice cream container at Giovanni L. Handels- und Produktions GmbH in Kiel must be labeled. Here, not only is the production environment cool and damp, but so are the ice cream containers themselves. Every 15 seconds, a continuous inkjet printer prints the cryogenic containers with product names, production and best-before dates, and EAN 13 barcodes. The printing system not only withstands the production conditions, but also ensures labeling that adheres reliably to frozen surfaces. Since the print head is completely sealed, no moisture can penetrate.

For traceability purposes, every single ice cream container at Giovanni L. Handels- und Produktions GmbH in Kiel must be labeled. Here, not only is the production environment cool and damp, but so are the ice cream containers themselves. Every 15 seconds, a continuous inkjet printer prints the cryogenic containers with product names, production and best-before dates, and EAN 13 barcodes. The printing system not only withstands the production conditions, but also ensures labeling that adheres reliably to frozen surfaces. Since the print head is completely sealed, no moisture can penetrate.

At Weber Marking Systems, we support you with state-of-the-art solutions to meet your identification, marking, labeling and related consumables needs. Our industrial labeling systems, as well as our Markoprint inkjet printers are perfectly suited for integration into your production lines!

Contact us Want to know more? Get in touch with our expert team!