Pipes and storage tanks, such as those found in the chemical industry or in the maritime and offshore sectors, usually contain substances that are hazardous to health and can pose a risk to people working in these environments. The new global ISO 20560 standard ensures greater occupational safety by standardizing the marking of pipes (above ground) and tanks.

Pipes and storage tanks, such as those found in the chemical industry or in the maritime and offshore sectors, usually contain substances that are hazardous to health and can pose a risk to people working in these environments. The new global ISO 20560 standard ensures greater occupational safety by standardizing the marking of pipes (above ground) and tanks.

The ISO 20560 standard regulates marking

In the past, there were various national and international standards for the labeling of pipes (in Germany, for example, DIN 2403) and tanks. The new global standard ISO 20560 provides for uniform hazardous substance labeling of aboveground pipes and tanks, which can be used to better identify the contents. The standardized labeling is intended to protect workers as well as subcontractors or even first responders on site when working on pipelines and tanks. Occupational accidents due to misunderstandings, for example during maintenance work, are to be prevented in this way.

In addition to information on the ingredients, the labeling also provides for clear GHS symbols or CLP pictograms that visualize the respective hazard class. This makes it immediately clear at a glance what the contents are and what hazards they pose. This is important when working on the pipelines and tanks and helps to avoid accidents.

What requirements for pipe marking does the ISO 20560 standard contain?

The pipe marking according to ISO 20560 is divided into two color zones: One zone in the basic color of the respective flow substance – this is, for example, the color orange for acids – and one zone in the safety color yellow. In the field with the basic color, information about the content such as the exact designation is printed. The field with the safety color contains appropriate warnings or warning symbols according to the GHS regulation or supplementary also to the ISO 7010 standard. The hazardous substance symbols must be placed on the side of the marking opposite to the flow direction. The flow direction must be indicated by means of an arrow.

The new standard also contains specifications on the size of the marking. For example, the size of the pipe marking depends on the respective pipe diameter. The pipe markings must be placed at appropriate intervals and in particularly hazardous areas such as wall penetrations.

In addition, the marking on pipes and tanks must be weather-resistant and withstand extreme temperatures, rain or high humidity, for example. It must also be resistant to chemicals and fuel. The marking must therefore not peel off under any circumstances or the GHS print become blurred.

Marking of pipes and tanks according to ISO 20560 standard:

- Two color zones

- Basic color of the respective substance/ingredients

- Safety color yellow

Symbols / Pictograms

Symbols / Pictograms- For hazardous substances: GHS symbol or CLP pictogram on the opposite side of the marking to the direction of flow.

- ISO 7010 warning symbols

- Marking size

- Oriented e.g. to the pipe diameter

- Indication of the flow direction

- By arrow

- Attaching the marking to pipes

- At appropriate intervals

- At danger points

How to mark pipes and tanks with hazardous material labels

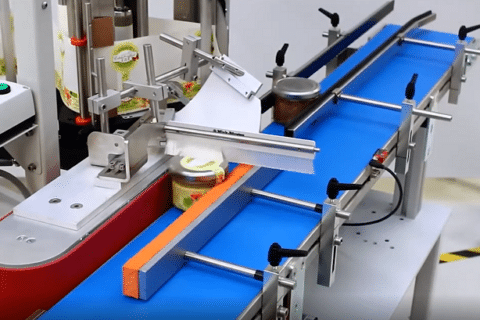

The marking of pipes and tanks according to the ISO 20560 standard can be done with adhesive labels. Weber Marking Systems offers a variety of label materials and adhesives for different requirements, including, for example, UV- or frost-resistant label materials as well as adhesives with very good adhesion even on rough substrates.

Creating ISO 20560-compliant hazardous material labels is possible with the Epson C7500 color label printer. With this color label printer, companies can easily create the desired color labels themselves. If the labeling requirements change, for example due to a new regulation or standard, they can react quickly and immediately print new information labels or hazardous material labels with the Epson C7500. The pigmented Epson DURABrite™ Ultra ink, for example, is particularly UV-resistant on matte label materials. It is ideally suited for GHS labeling.

Alternatively, it is possible to obtain ready-printed safety or hazard labels. As a label manufacturer, Weber Marking Systems produces all types of labels, including those for pipe marking.

Get in touch with our marking and coding experts

Symbols / Pictograms

Symbols / Pictograms