Cardboard boxes are perfect for transporting goods safely. Everything it takes is the right label for logistics, shipping or traceability. In some of these cases, costs can be reduced if you choose inkjet printers over labeling systems. But when exactly is direct marking just as suitable as applying labels? We compared both methods in terms of print quality, flexibility and speed. Find out which method is best for you!

Labeling cardboard boxes

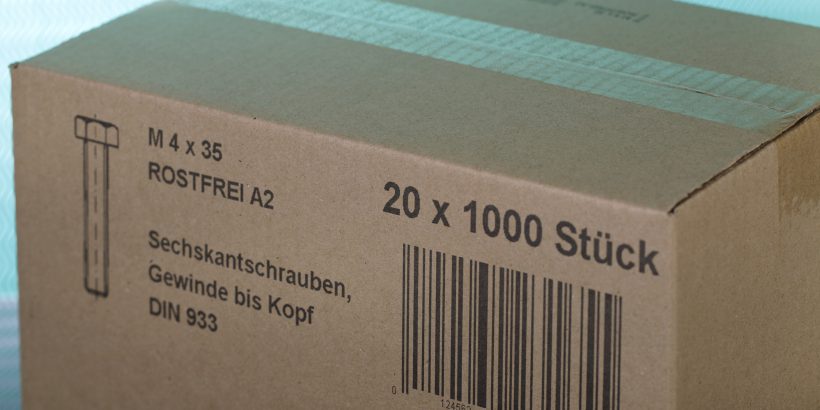

White labels paired with black thermal-transfer printing achieve excellent print resolution. Furthermore, they compensate for unevenness on corrugated cardboard surfaces. Both factors are important when external partners and customers are supposed to read out markings such as barcodes or data matrix codes without errors. For example, retailers often demand very high print quality that complies with ANSI Code Grade A.

White labels paired with black thermal-transfer printing achieve excellent print resolution. Furthermore, they compensate for unevenness on corrugated cardboard surfaces. Both factors are important when external partners and customers are supposed to read out markings such as barcodes or data matrix codes without errors. For example, retailers often demand very high print quality that complies with ANSI Code Grade A.

In addition, labeling machines are more adaptable than inkjet printers. You can label your goods sideways, from above or below and around the corner. Even with variable carton heights, they label very accurately thanks to extendable dispensing temples and contactless labeling techniques. The maximum printing speed is 400 mm / s.

Directly printing labels on cartons

The print quality of ink on cardboard is usually slightly lower compared to labels, as cardboard is very absorbent. Nonetheless, large-character piezo inkjet printers also achieve a high printing resolution, which is ideal for coding tasks in warehouse logistics, picking or quality assurance. Whether the color and quality of the cardboard allow the desired print image, must be checked individually.

The print quality of ink on cardboard is usually slightly lower compared to labels, as cardboard is very absorbent. Nonetheless, large-character piezo inkjet printers also achieve a high printing resolution, which is ideal for coding tasks in warehouse logistics, picking or quality assurance. Whether the color and quality of the cardboard allow the desired print image, must be checked individually.

Specific advantages of direct marking are the higher maximum printing speed (up to 1,000 mm / s) and lower printing costs (about 60% less per 1,000 prints). At the same time, the font size can be changed during the current printing process, which is not possible when labeling. Cardboard surfaces can be printed on the side or top, but the printhead must be installed very close to the surface.

Labeling vs direct label printing in comparison:

Labeling

| Direct printing

(piezo inkjet) | |

| Maximum resolution | 600 dpi | 200 dpi |

| Printing quality | Pin sharp thermal transfer printing on label material | Absorbency of the cardboard reduces print quality |

| Scannability | Excellent (black print on white label) | Reduced on brown cardboard |

| Maximum print size | Height: variable / maximum width: 160 mm | Width: variable / maximum height: 800 mm |

| Print of text, images, graphics and codes | Possible | Possible |

| Various printing colors | Possible | Possible |

| Investment costs | Comparable | Comparable |

| Operating cost / consumables | Higher (labels, thermal transfer ribbon) | Lower (ink) |

| Printing costs per 1,000 prints* | Higher (ca. 9.50 €) | Lower (ca. 3.10 €) |

| Maximum printing speed | 400 mm / sec | 1.000 mm / sec |

| Adjustability of labeling plate / printhead | Adjustable and variable, corner wrap is possible | Static, not adjustable |

| Print position |

|

|

| Format change | No change of label size possible while process is running | Change of print size possible while process is running |

| Suitable surfaces | Absorbent and non-absorbent substrates | Absorbent and slightly-absorbent substrates |

| Maximum distance to the carton | Large (due to extendable dispenser and/or blow-off technology) | Small (printhead must sit close to surface) |

* in the format 105 x 150 mm, printed image see above, at 1 million prints p.a.

Conclusion

While print-and-apply-labelers are very versatile, cost-effective inkjet printers meet demands of many applications as well. In direct comparison, labels provide a better readability and are ideal for external logistics. On the other hand, inkjet printers work cheaper and faster. The print quality is suitable for many applications in internal logistics. The right decision often depends on the individual case. The experts at Weber Marking Systems will be happy to advise you personally and at no cost!

Get in touch for more information and FREE consultation

(print and apply)

(print and apply)

Hi

Good comparison between labeling and direct printing. Personally, labeling is better by resolution (depending on printer), and my preference is due to the barcode reader. For which label must be clear and legible.

regards

Nahum