Modern labeling systems are automation solutions that can optimize any production line. Integrating an automatic labeling system offers many benefits such as making production more efficient and agile while guaranteeing traceability all along the supply chain, maximising precision in the label application and minimising human mistake.

In this article, we present the best solutions for automatic label application and introduce their features, including how they perform and the industries in which they fit best.

Label dispenser or Tamper Evident dispenser

– Label dispenser Alpha HSM:

The Alpha HSM is the most famous label dispenser within our portfolio. It allows the application of up to 2.000 labels per minute and is optimal for hostile environments given its protection class IP65. Thanks to its modular construction, the Alpha HSM can be built to meet the specific needs of each and every production line.

The Alpha HSM is usually chosen by pharmaceutical companies and OEMs. However, the construction and food sectors also use it quite often.

– Label dispenser Tamper Evident:

When it comes to the pharmaceutical industry, ours best-seller is undoubtedly the Legi-Air 4050B Corner Wrap. However, we must not forget the Tamper Evident 122, the first label dispenser within the Weber Marking Systems’ portfolio dedicated to fulfil the needs of the pharmaceutical sector. Available in both right-hand and left-hand versions, the Tamper Evident applies transparent seals on boxes and medicines in order to prevent counterfeiting and tampering.

When it comes to the pharmaceutical industry, ours best-seller is undoubtedly the Legi-Air 4050B Corner Wrap. However, we must not forget the Tamper Evident 122, the first label dispenser within the Weber Marking Systems’ portfolio dedicated to fulfil the needs of the pharmaceutical sector. Available in both right-hand and left-hand versions, the Tamper Evident applies transparent seals on boxes and medicines in order to prevent counterfeiting and tampering.

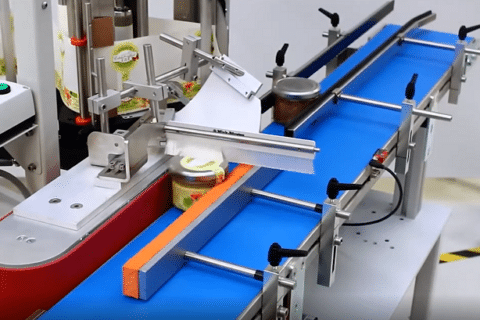

Print & Apply systems: Solutions for secondary packaging

– Label printer and dispenser Legi-Air 4050Be Electric:

The Legi-Air 4050B is one of our most famous label printers and dispensers.

This electric solution can save up to 80% in compressed air consumption, representing a significative saving in the system’s Total Cost of Ownership.

The Legi-Air 4050B is available in five versions: the Electrical Linear, the Electrical Belt, the Electrical Swing Arm, the Corner Wrap and the Blow Box.

Each version of the Legi-Air 4050B is built upon the modularity concept, which allows the easy replacement of every single part while facilitating maintenance.

Chosing between the five versions of the Legi-Air 4050B depends on several factors. For example:

– The Electrical Belt is a great labeling solution for high volume packaging lines.

– The Electrical Corner Wrap, on the other hand, is the ideal solution for pharmaceutical packaging lines.

– The Electrical Blow Box, on its turn, is best suited for fragile products that require a contactless application.

– Label printer and dispenser Legi-Air 4050E:

The Legi-Air 4050E is Weber Marking Systems’ best-seller. What makes this label printer and dispenser stand out is its robustness and versatility.

This system has been developed to work in industrial and hostile environments, including working 24/7. When in sync with another Legi-Air 4050E, they are able to function in Zero Downtime Mode.

Thanks to the wide variety of applicators, the Legi-Air 4050E can fulfil any labeling need.

Its flexibility is not only a result of its dispenser but also of its operation: its integrated cutting-edge technology enables an incredible operator-machine interaction. A multilingual, color-touchscreen display turns a system’s operation into an intuitive and agile labeling experience. In addition, the Legi-Air 4050E counts with all the required interfaces for the 4.0 industry.

Thanks to its robust construction and multiple application possibilities, the Legi-Air 4050E is usually OEM’s preferred choice.

Labeling solutions for pallet: Print & apply for tertiary packaging

– Label printer and dispenser for pallets AP182:

The very end of the line is surely tertiary packaging. Weber Marking Systems’ labeling solutions are not only dedicated to secondary packaging but also accompany clients and the ever-growing industry offering solutions for tertiary packaging.

Intrinsically safe, the AP182 is Weber’s label printer and dispenser for pallets. Leveraging the technology developed for the Legi-Air 4050B, the AP182 is also electric and allows the application of 2 or 3 labels on adjacent sides of a pallet in either orientation, portrait or landscape, reaching up to a performance of 90 pallets an hour, and when applying two labels, 120 pallets an hour.

Thanks to its protective cabinet, the AP182 is the choice of packaging lines that need to resist hostile environments and extreme temperatures.