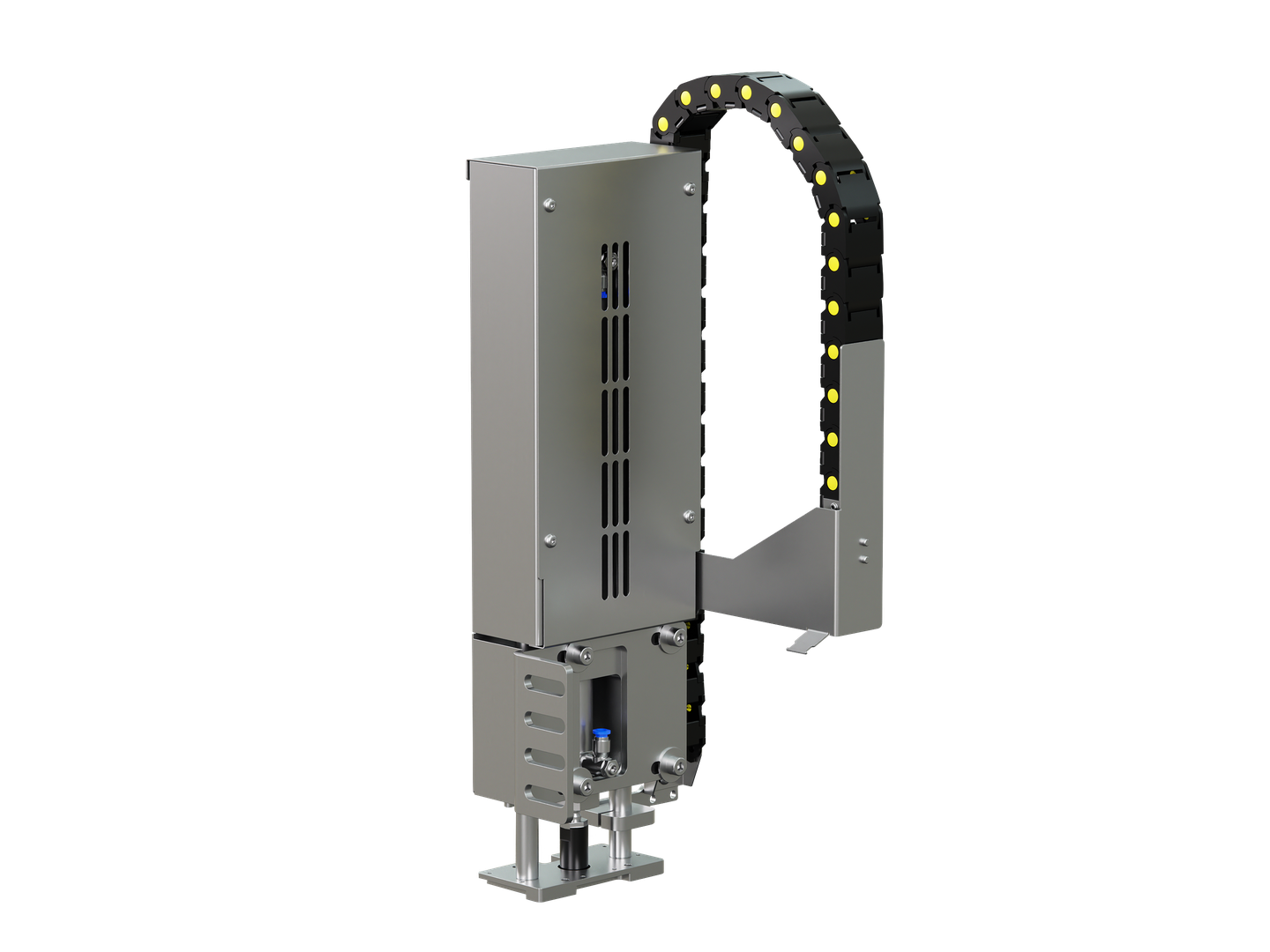

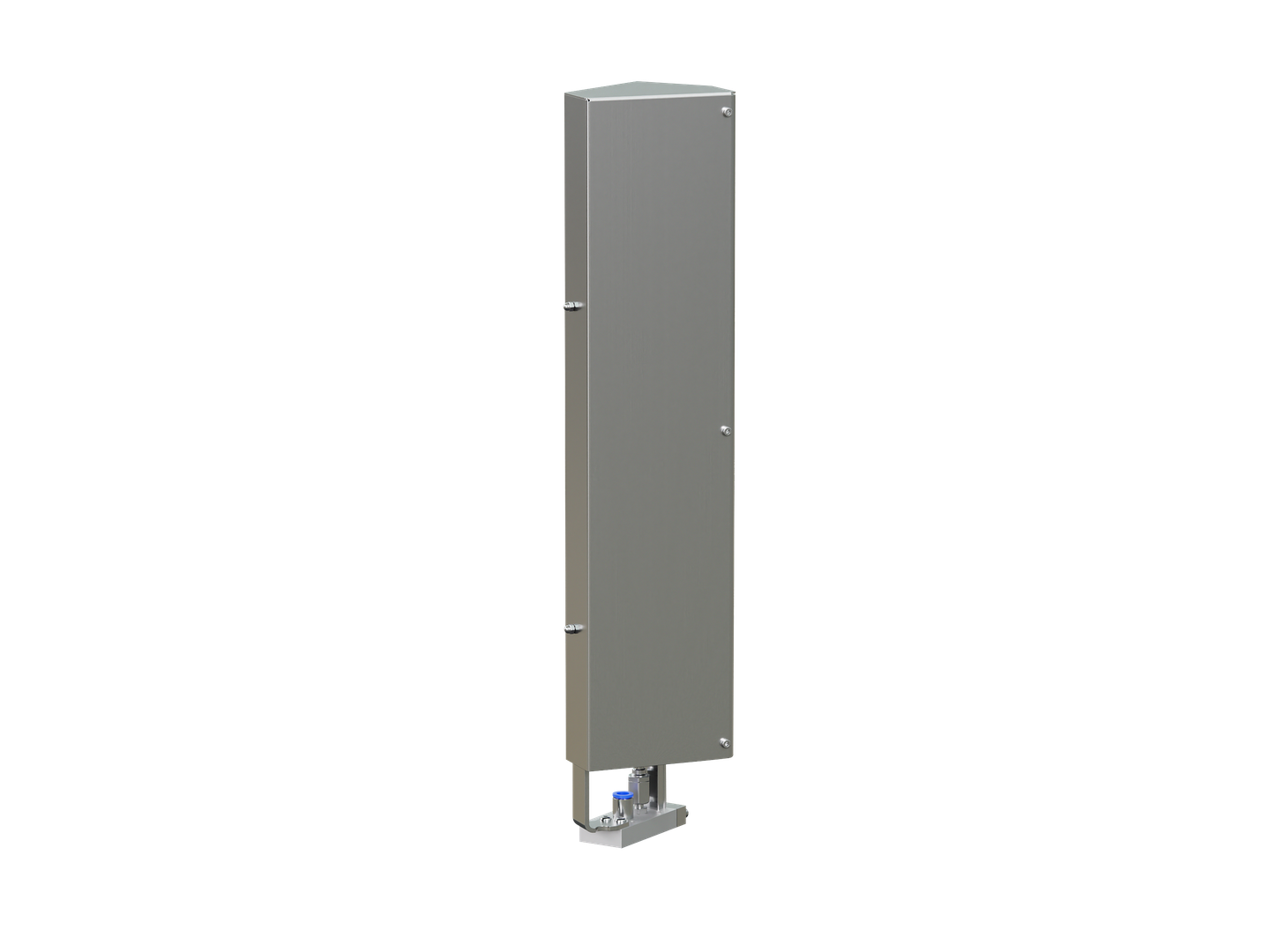

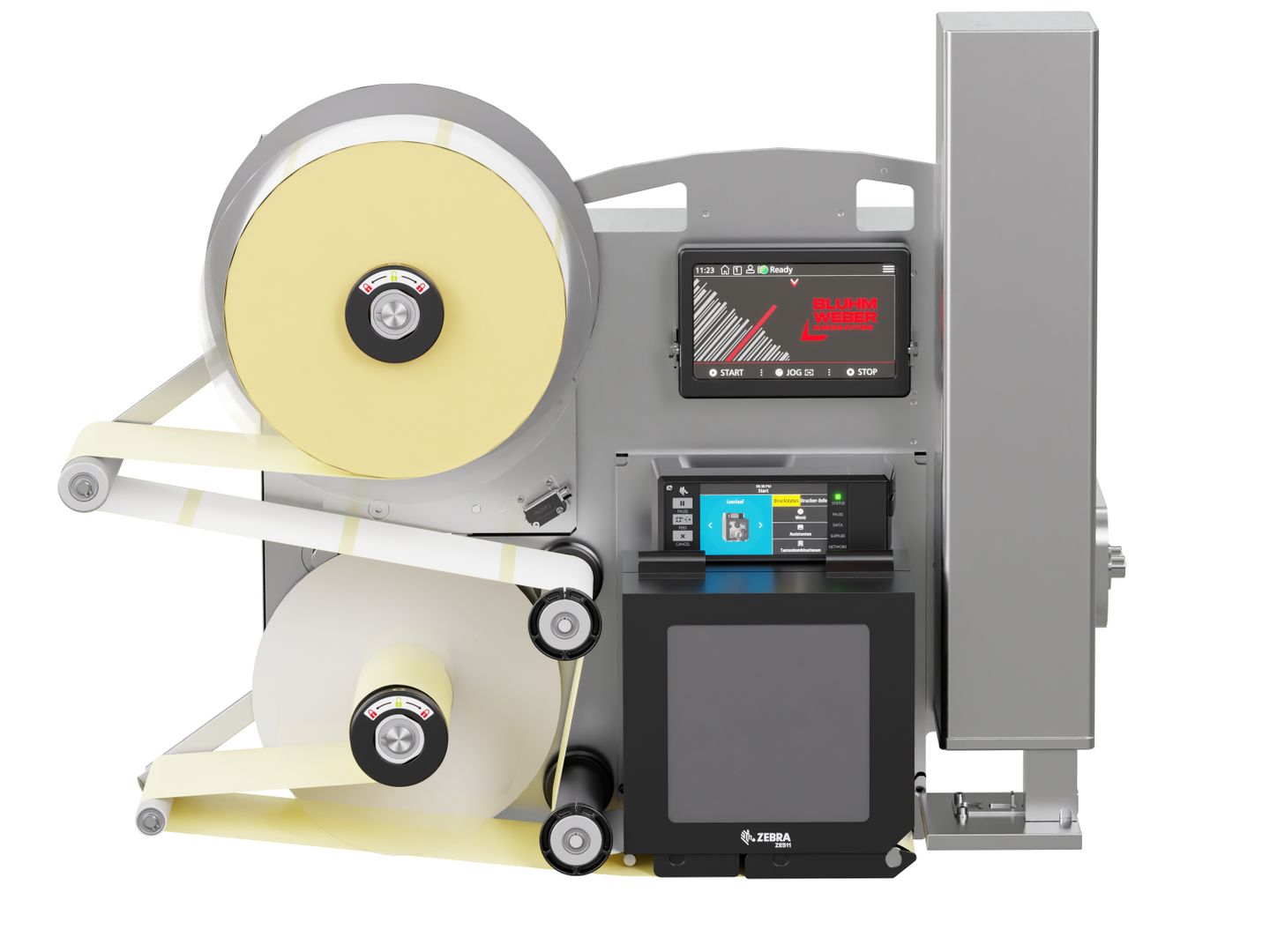

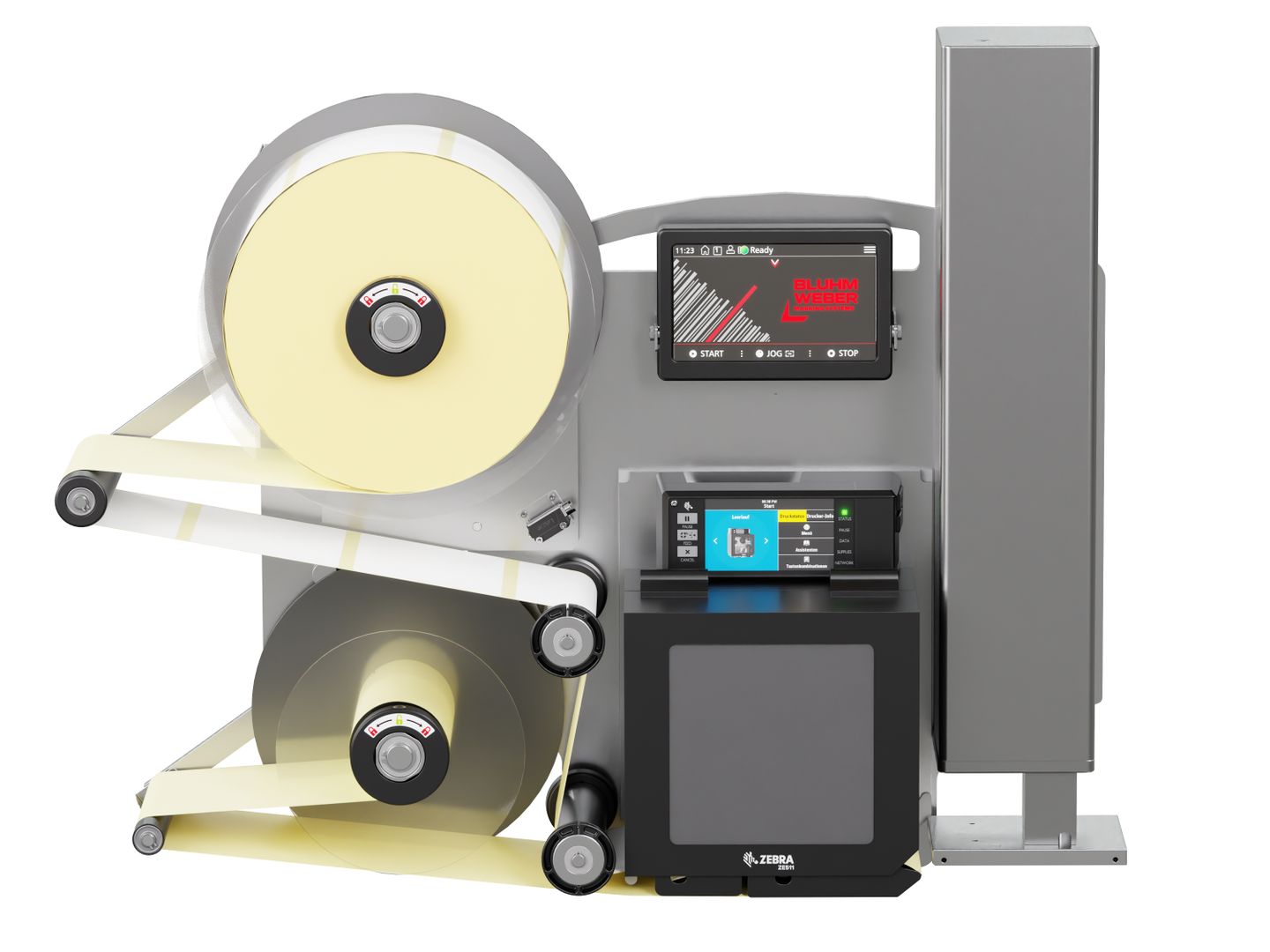

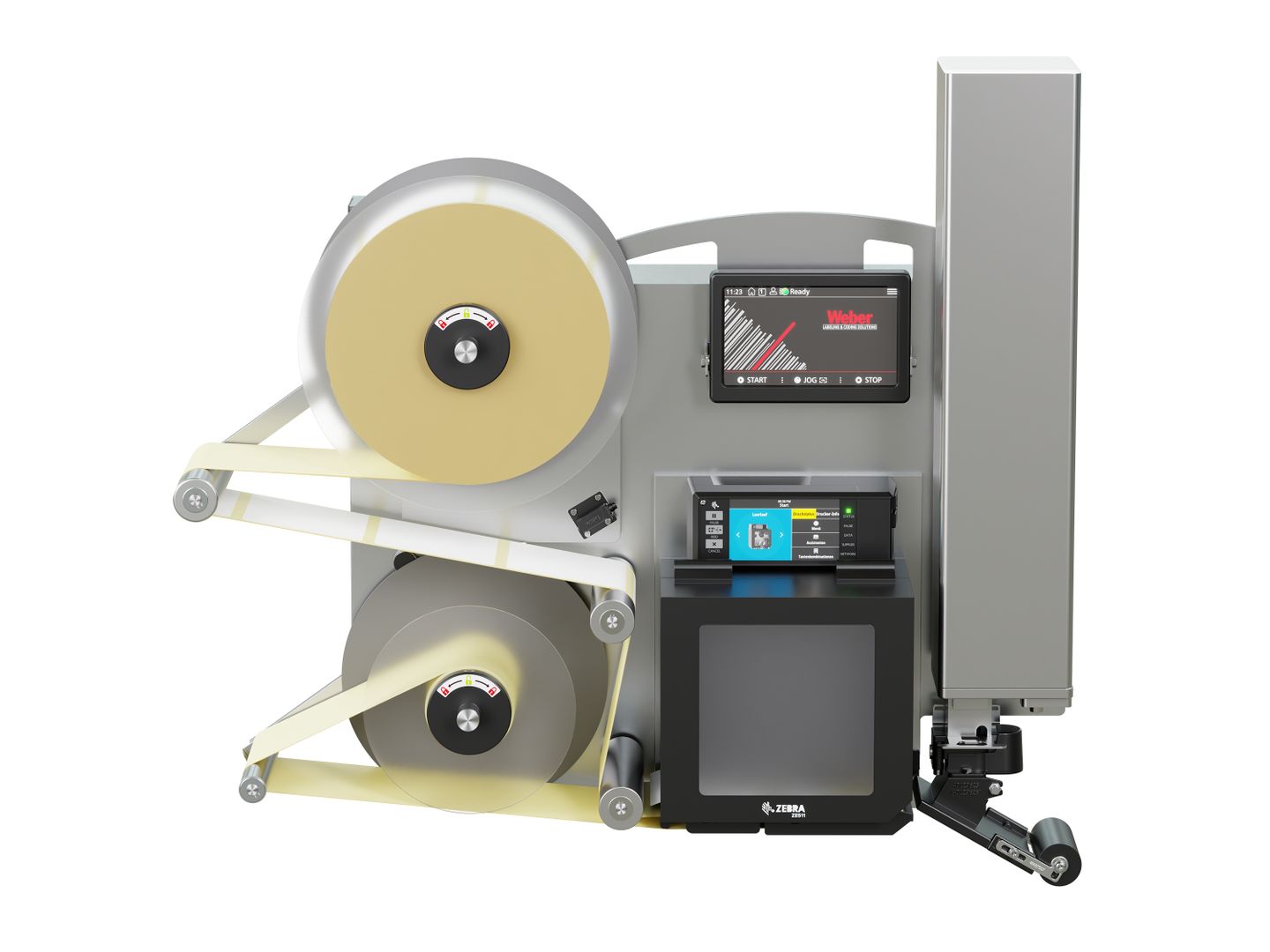

Extremely adaptable to harsh industrial environments

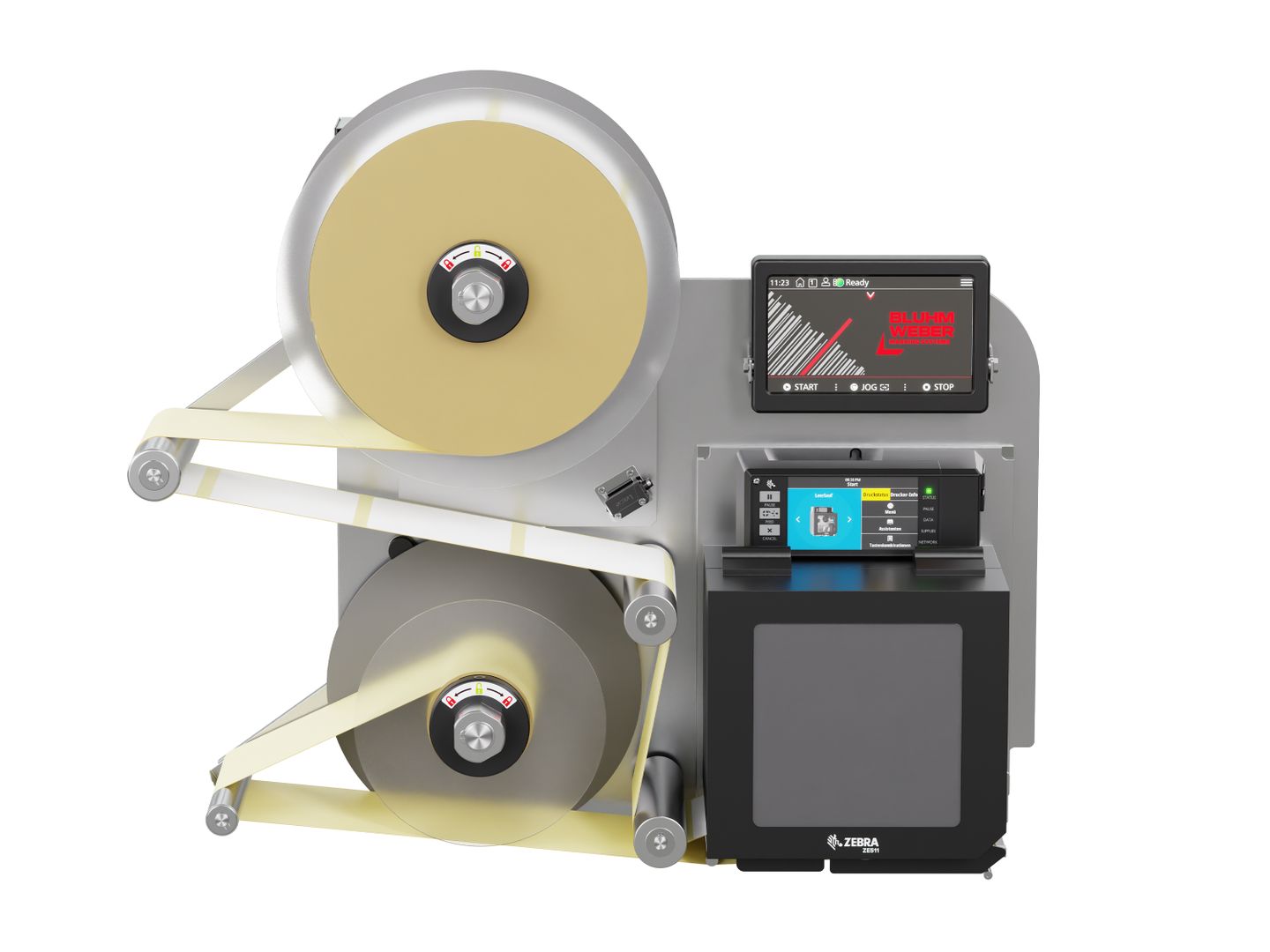

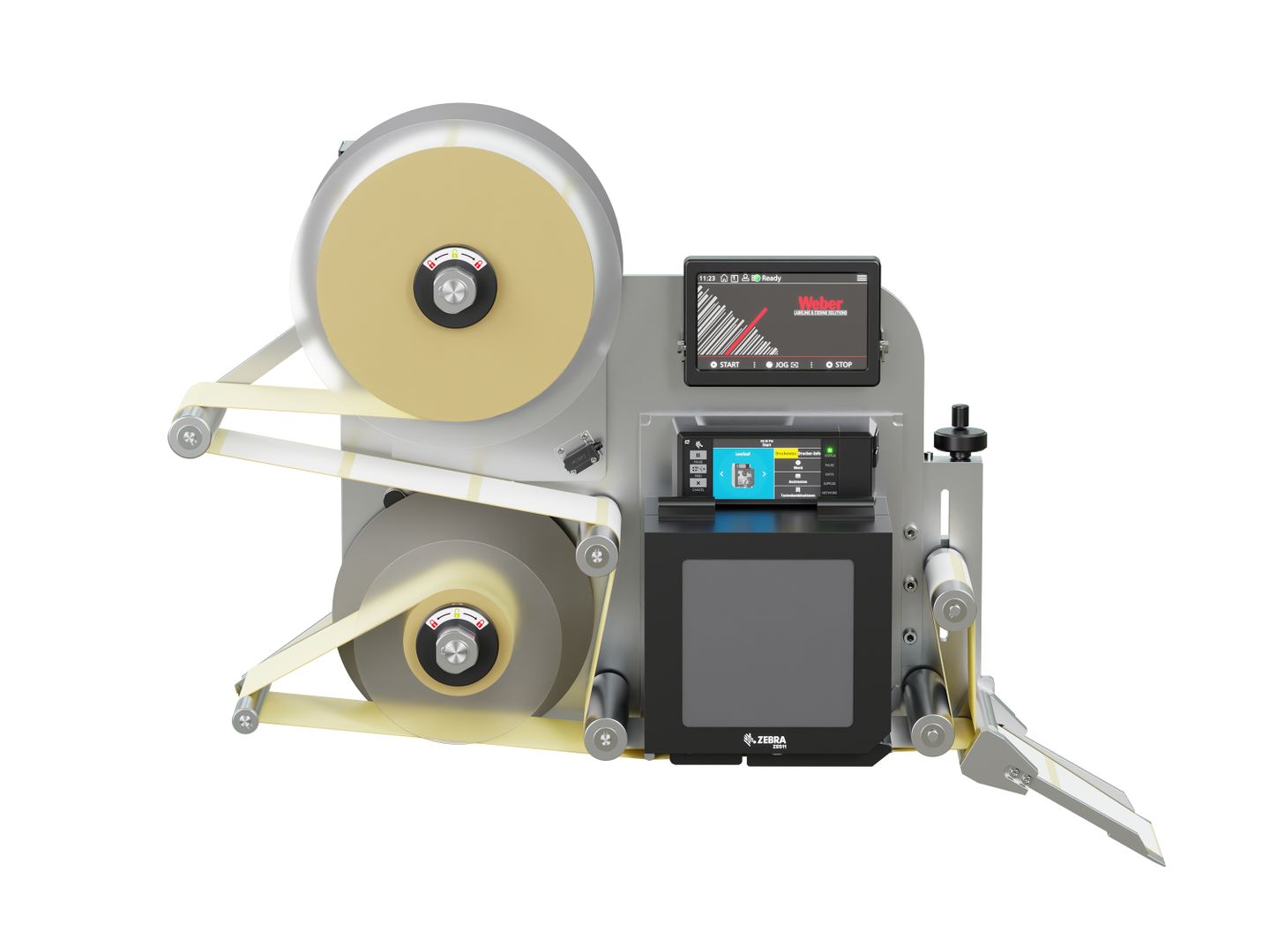

The Legi-Air 4050I label print applicator with stainless steel protective housing is particularly robust. It is housed in a sturdy protective cabinet that protects against dust, cold and heat and enables reliable labeling, especially in demanding industrial environments. Climate control solutions such as pressurisation kits, heating or cooling are optionally available. A stop valve, which prevents the applicator from dropping unintentionally, ensures maximum safety. Different applicators are available depending on the application.